Operation, Maintenance, Disposal – Silverline Air Hammer Set 5pce User Manual

Page 8

www.silverlinetools.com

7

394970

5pce Air Hammer Set

• Air lines fitted with matching female quick connectors will now be a push

fit to the tool

Air supply connection

• This tool should be connected to a clean, dry air supply with inline oiler

and water separator

• Do not allow supply pressure to exceed the maximum stated (see

“Specifications”)

• Ensure that water is drained from air system daily

• Ensure that all parts of the system (hoses, couplers, etc.) are correctly

rated for the air pressure to be used

Fitting accessories

WARNING: Always disconnect the tool from the air supply before examining

or changing accessories. Examine your chisels before using them. If an

accessory is worn or cracked, DO NOT use.

1. Insert the required accessory into the head of the air hammer

2. Thread the Quick Change Spring (1) over the accessory and onto the

screw threads on the head of the air hammer

3. Tighten the Quick Change Spring (1) so that the screw threads are fully

engaged, the end loop is positioned vertically (12 o'clock position),

and the shank of the accessory is retained within the end coil, as

shown in the ‘Product Familiarisation’ image above

4. Pull the accessory back and forth several times by hand, to check that

it is securely retained

Note: Accessories can also be removed and fitted when the Quick Change

Spring (1) is screwed on to the body of the tool. Carefully push the end coil

of the spring sideways, so that the collar of the accessory can pass the

retaining spring coil.

Setting tool power

Note: This air hammer features a built-in pressure regulator.

• The tool speed can be adjusted by rotating the Air/Torque Control Dial

(4) as required

Operation

1. Grip the air hammer firmly with both hands

2. Rest the tip of the accessory on the workpiece you wish to chip/cut

3. Gently press the trigger and move slowly along the workpiece

Note: DO NOT allow the air hammer to run in ‘idle rotation’ for an extended

period of time. This will shorten its life.

Note: DO NOT exert excessive pressure on the tool - let the tool do the

work. If the material is not being cut as intended, examine the accessory

for wear and damage and replace if necessary. Consider changing to a

different accessory.

WARNING: Be aware that air tools may hold residual pressure after use.

Always bleed air pressure from the tool after shutting off air supply.

Accessories

• Accessories for this tool, including a 4pce Chisel Set (598430), are

available from your Silverline stockist. Other spare parts can be obtained

from your Silverline dealer or

www.toolsparesonline.com

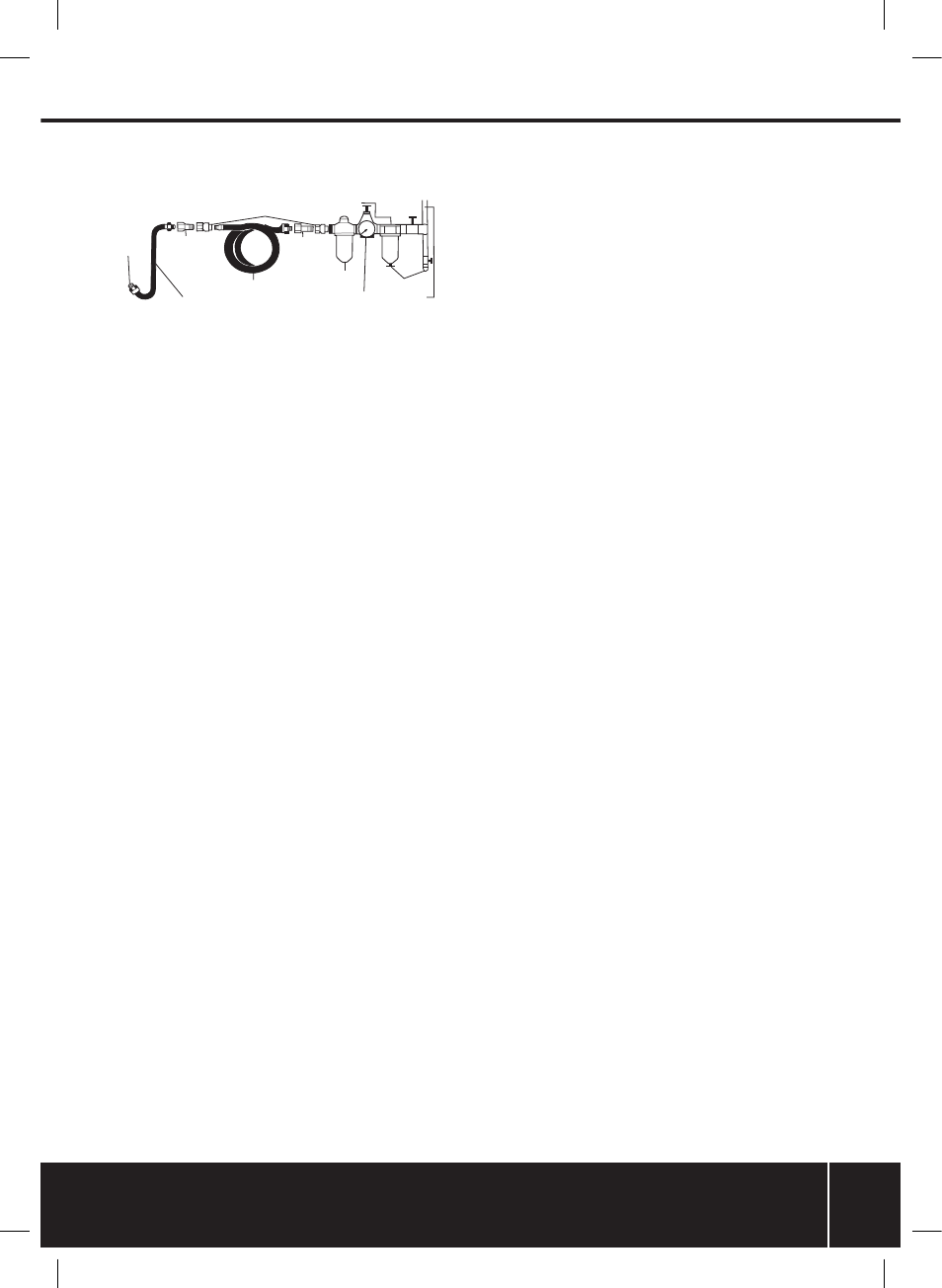

TO YOUR

AIR TOOL

LEADER HOSE

NIPPLE

QUICK COUPLER

WATER SEPARATION

OILER

NIPPLE

REGULATOR

DRAIN DAILY

AIR SUPPLY

RECOIL HOSE

Maintenance

WARNING: Always disconnect from the air supply and depressurise before

cleaning or carrying out any maintenance.

Cleaning

• Keep your tool clean at all times. Dirt and dust will cause internal parts

to wear quickly, and shorten the machine’s service life. Clean the body of

your machine with a soft brush, or dry cloth

IMPORTANT: There is very little that can go wrong with your air tool and it

should be noted that when an air tool fails to work it is generally because

the internal workings have corroded due to dirty, wet air and failure to

follow the instructions given below.

Daily maintenance procedure: Disconnect from the air supply, pour the

equivalent of a tablespoon of oil into the air intake. Operate the machine at

low speed to thoroughly lubricate all internal workings.

• If the machine is in constant use or used for long periods at a time, a

combined filter/lubricator must be fitted. There must be an air filter fitted

at all times

• Use air tool oil. DO NOT UNDER ANY CIRCUMSTANCES USE NORMAL

ENGINE OIL

• Failure to comply with the operating and maintenance instructions may

invalidate the guarantee

Storage

• Store this tool carefully in a secure, dry place out of the reach of children

Disposal

• As with other power tools, air tools should not be disposed of with

household waste

• Air tools may contain traces of tool oil and other lubricants and so must

be recycled accordingly

• Contact your local waste disposal authority for information on the correct

way to dispose of power tools

394970_Z1MANPRO1.indd 7

10/07/2013 16:01