Comfort-Aire AFM42-60 User Manual

Page 8

8

Multi-Position Air Handler with Hydronic Heat with X13 Motor

HWCGxxX0A

Heat Controller

8) Adjust the water heater thermostat so that the water

temperature entering the hot water coils is 120 –

180ºF depending on the amount of heat required by

the structure. This is done with the unit energized

and operating long enough for all temperatures to

stabalize.

Note: Massachusetts applicable diagram at end of manual

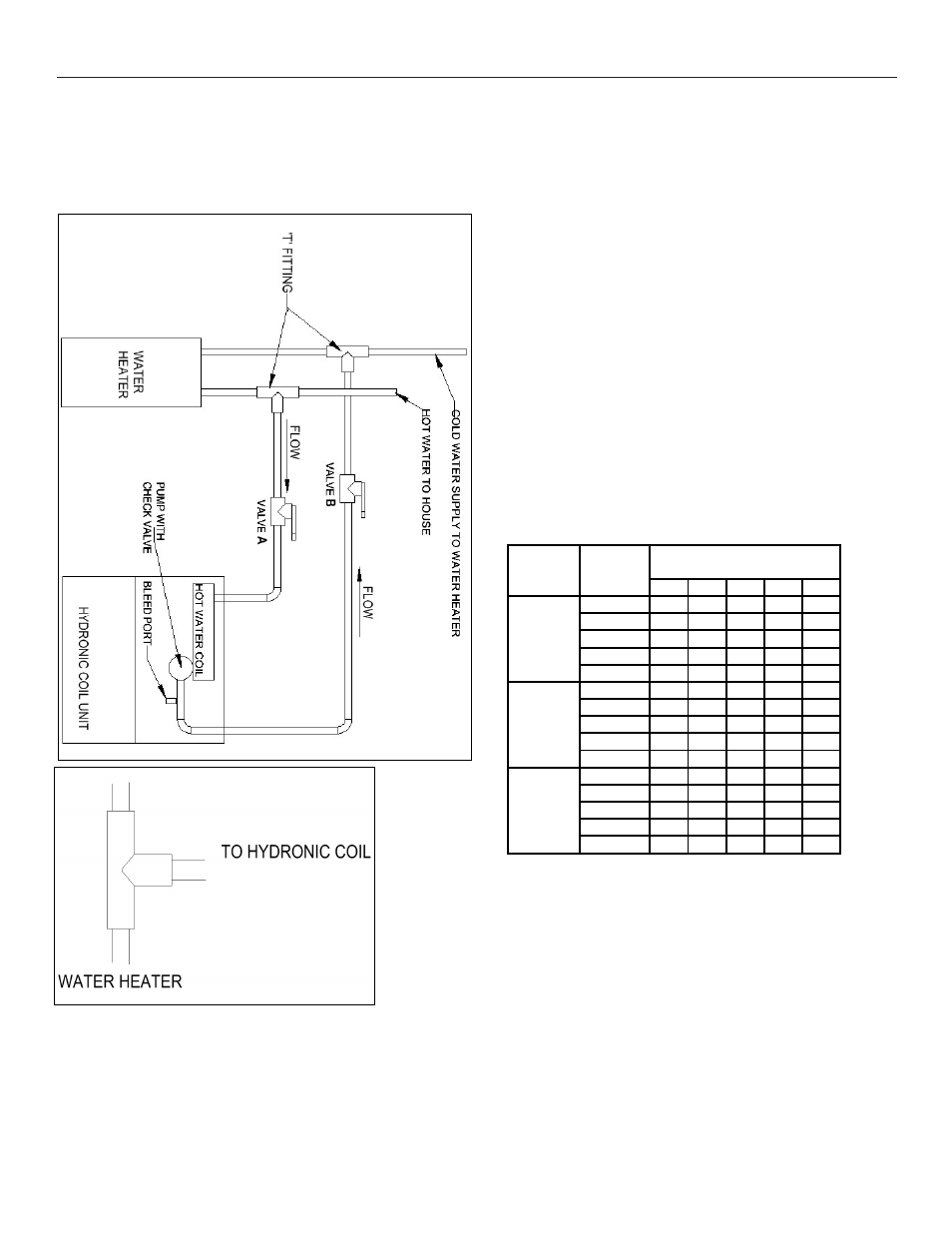

Fig.11. Schematic of hydronic unit set up and typical “T”

installation

After all connections are made, start-up and check-up

must be performed before proper evaluation of the entire

system can be made. Make sure that heat anticipator is

properly set as noted on thermostat instructions.

Load requirements can vary in each residence and it

may be necessary for the installer or homeowner to

make slight adjustments to the heat anticipator setting

for longer or shorter cycles. It is recommended to

change the setting no more than plus or minus 0.05

amps at a time. Greater changes can cause the unit to

rapid cycle or remain on excessively. To properly check

the unit's operation, the installer should have an

electrical current measuring device (0-10 amp Amprobe,

Fluke), air pressure measuring device (0-1.0 in slope

gauge), and a temperature-measuring device (0-200ºF

thermometer).

Install the Amprobe to measure blower current, the slope

gauge to measure static air pressure at the units and the

temperature device to measure unit supply and return air

temperature. Before taking measurements, be sure that

all registers, grilles and dampers are open or set to their

proper positions. Be sure that clean filters are in place.

Temperature measuring device must be installed to

obtain average temperature at both inlet and outlet. For

outlet, measure temperature of each main trunk at a

location far enough away to avoid heater radiation and

read the average temperatures. Table 1 below shows

the CFM that should be achieved at various external

static pressures

0.10 0.20 0.30 0.40 0.50

Tap 5

900 853 797 738 673

Tap 4

670 646 613 592 553

Tap 3

500 476 452 421 400

Tap 2

900 853 797 738 673

Tap 1

400 381 360 339 312

Tap 5

1150 1087 1030 975 910

Tap 4

1080 1048 1010 960 895

Tap 3

900 862 825 796 745

Tap 2

700 663 632 600 552

Tap 1

500 473 449 421 395

Tap 5

1850 1806 1752 1700 1652

Tap 4

1704 1656 1600 1532 1479

Tap 3

1494 1461 1426 1400 1364

Tap 2

1350 1310 1272 1229 1175

Tap 1

676 652 621 600 559

CFM V. External Static

Pressure

AFM18-24

AFM30-36

AFM42-60

SPEED

TAP

MODEL

Table 1. CFM delivered at various external statics

Electric Heat Controls

•

Turn on power supply. Set thermostat fan switch to

on. Set the cooling indicator to maximum, heating to

minimum. System switch may be on heat or cool.

Check slope gauge measurement against

appropriate air flow chart. Make damper, register

and motor speed adjustments to obtain required

airflow.

•

Set thermostat fan switch to auto, system to heat

and thermostat heating indicator to maximum heat.

Blower should start and all heat be energized.

•

Check air flow using temperature rise method.

HWCG48/60X0A

HWCG36/42X0A

HWCG24X0A