Caution, Field – installed expansion valve coils, Warning – Comfort-Aire AFM42-60 User Manual

Page 4

4

Multi-Position Air Handler with Hydronic Heat with X13 Motor

HWCGxxX0A

Heat Controller

Fig. 2 shows the recommended position for the TXV bulb

installation in the horizontal plane.

The TXV sensing bulb

SHOULD be mounted using the

metal clamp provided. In order to obtain a good

temperature reading and correct superheat control, the

TXV sensing bulb must conform to ALL of the following

criteria:

1) The sensing bulb must be in direct and

continous contact with the suction line

2) The sensing bulb should be mounted

horizontally on the suction line.

3) The sensing bulb must be mounted above and

between the 4 and 8 o’clock position on the

circumference of the suction line.

4) The sensing bulb must be insulated from outside

air.

TXV BULB POSITION

4 O'CLOCK OR

8 O'CLOCK

METAL STRAP

SUCTION/VAPOR LINE

Fig.2. Recommended location of the TXV bulb in a

horizontal orientation

The mounting location and insulation guards the sensing

bulb from false reading due to hot outside air or liquid

refrigerant formed inside the suction/vapor line.

As recommended earlier, the TXV sensing bulb should

be mounted in a horizontal plane in relation to the

suction/vapor line. However, in case such a mounting is

not feasible and the sensing bulb has to be mounted

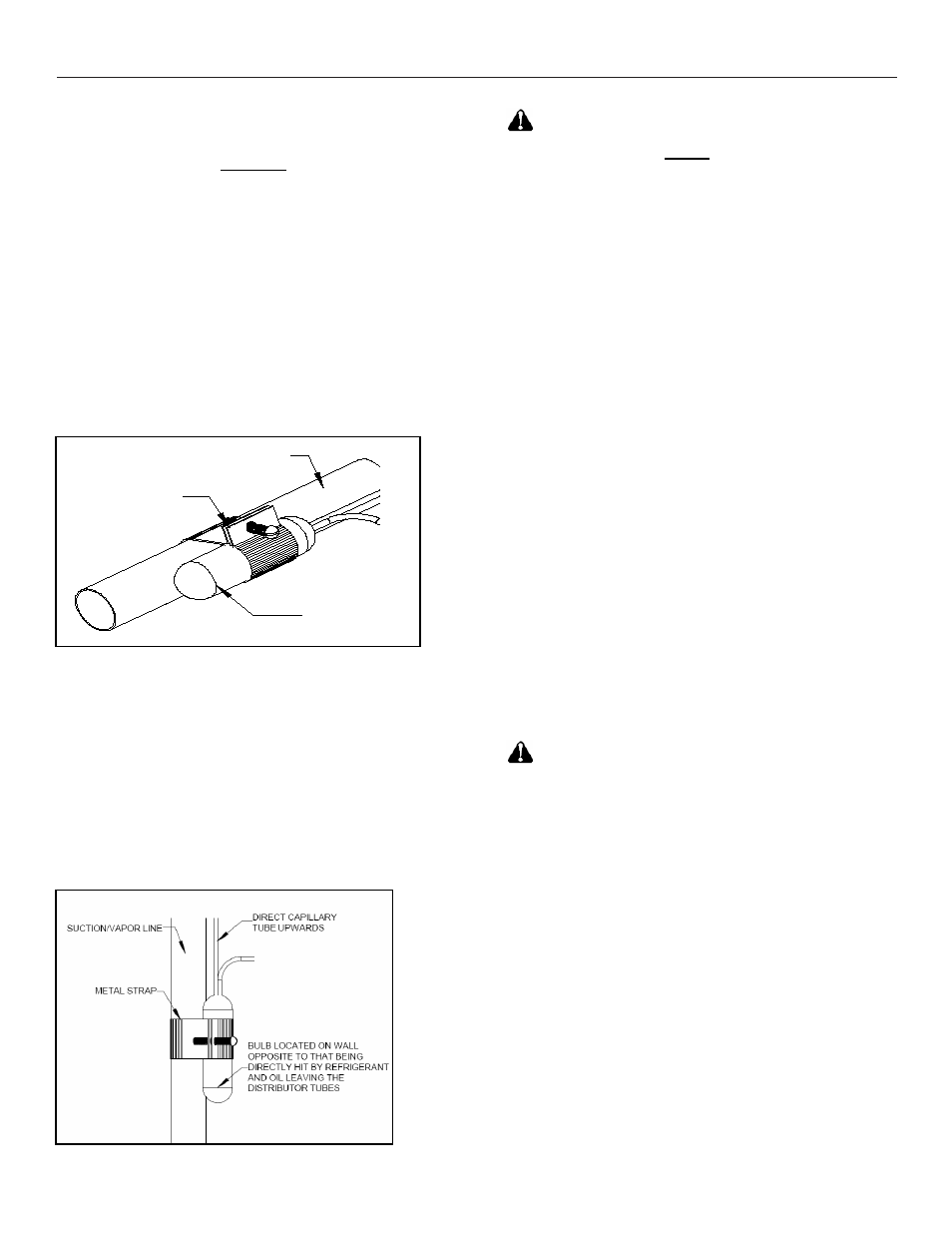

vertically; then place the bulb as shown in Fig.3.

Fig.3. Sensing bulb mounted in a vertical orientation

CAUTION

If the TXV sensing bulb is mounted

vertically; the capillary

MUST be directed upwards. The

bulb must be mounted on the wall opposite to that being

directly hit by the refrigerant and oil leaving the

distributor tubes.

Field – Installed Expansion Valve Coils

Remove the valve identification sticker from the valve

and place it adjacent to the model number on unit name

plate.

When installing an expansion valve, it is not necessary

to remove all the access panels and slide the coil out of

the housing.

1) Disassemble the flowrator body using two

wrenches. Unscrew the body with a counter-

clockwise motion.

2) Replace the white Teflon seal in place (located

between the halves).

3) Remove the existing flowrator piston using a

small wire or pick.

4) Inspect the TXV box to confirm that the valve is

compatible with the refrigerant in the system.

5) Remove the valve from the box and note the

location of the inlet side (threaded male port)

and the outlet side (female swivel nut port).

6) After ensuring that the white Teflon seal is still in

place inside the flowrator body, screw the

female swivel nut onto the flowrator body.

7) Place the attachment nut on the liquid line.

8)

Braze the stub-out portion to the liquid line and

let cool.

WARNING

Do not attempt to touch the braze

joint while hot. Touching it may cause sever burns.

9) Remove the additional white Teflon seal ring

from the box and place on the shoulder just

inside the inlet port. Screw the nut attached to

the stub-out portion of the flowrator body onto

the inlet port of the TXV.

10) Tighten all connections taking care to use proper

back up.

Some coils come with a Schrader valve on the suction

line. If a Schrader port is present

11) Remove valve stem from the Schrader port

mounted on the suction line

12) Screw flare nut on TXV equalization tube in to

the Schrader valve stem

Coils without Schrader Ports

11) Locate a convenient spot on the suction line

and punch a ¼” hole with a pick or other suitable

tool.