Rivera Primo Brute III Extreme User Manual

Page 2

NOTE: Replace the OEM hex-head bolt (Dyna Glide only) with the

button-head Allen bolt provided in the kit. TORQUE THE BUTTON-

HEAD BOLT TO 29 FOOT POUNDS.

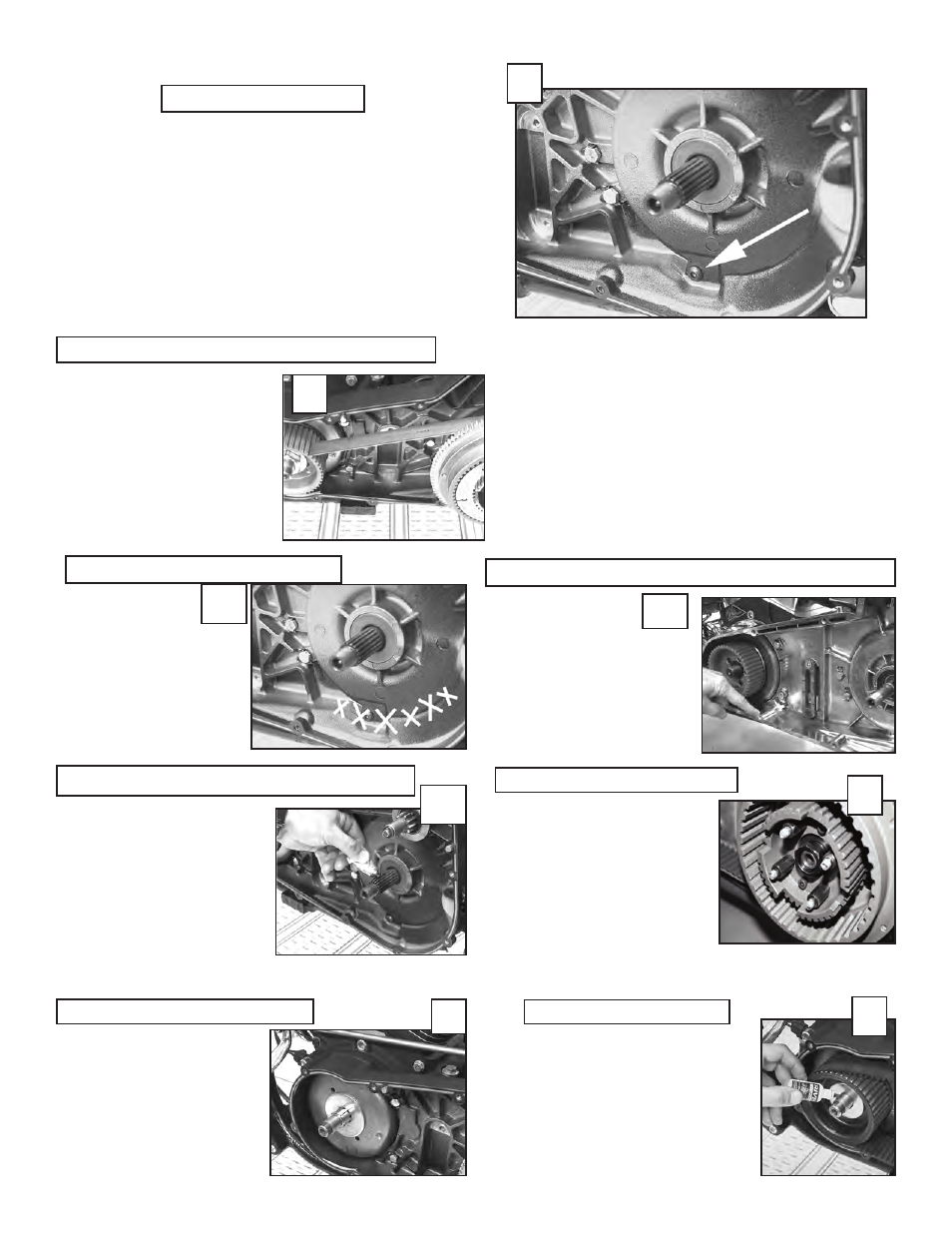

This inner primary (Early

Evo) has had a tab removed

to allow belt clearance in

the area indicated. Most in-

stallations require some

grinding on the inner and

outer primarys.

Install front pulley (together with

front inside guide plate) & rear

pulleys without the belt & check

alignment as shown(straight

edge flush with rear of ring-gear

lines-up with outer edge of front

pulley) remove pulleys and pro-

ceed with installation. If align-

ment isn’t satisfactory see photo

8. The provided .100” washer can

be used to space the front pulley

outward as needed.

After ensuring proper pul-

ley alignment, again check

the areas indicated in the

photo for belt and/or pul-

ley clearance. Always

check rear-pulley and belt

clearance here before op-

erating the motorcycle.

5

5A

Check pulley alignment with a straight-edge

Check primary belt clearance here

Check for proper belt clearance

Install Allen head bolt

4

Apply a thin coat of the special

Primo grease supplied in the kit

to the splines of the transmis-

sion main-shaft to act as both a

corrosion inhibitor, & lubricant.

The grease also acts as a cush-

ion for the splines on the trans-

mission

main-shaft

during

operation.

5B

Apply grease to the main-shaft splines

Install the rear pulley (clutch bas-

ket) & belt. Apply Rivera blue

thread lock to the main-shaft

threads as shown. INSTALL THE

CLUTCH HUB NUT & TIGHTEN

TO 70-80 FOOT POUNDS OF

TORQUE. (The center adjustment

screw with o-ring will prevent

transmission oil from leaking thru

the main-shaft into the clutch

pack).

Install rear pulley & belt.

A .100” washer may be

needed behind the front pul-

ley on some Dyna-Glide &

Softail applications.

7

Install washer as needed.

3

Install front pulley, washer & inner/outer

guides. Use 1-2 drops of blue thread-lock

on the threads of the motor shaft. IN-

STALL & TIGHTEN NUT TO FACTORY

SPECS (150-165 FOOT POUNDS) using a

quality torque wrench.

8

Use thread-lock here.

Shims are manufactured from high quality steel, precision

ground for parallel & flat surfaces to ensure perfect pulley

alignment. Correct pulley alignment & correct belt tracking

are a must for long belt life. These shims make pulley align-

ment easy. Shims are available in .020", .030", .050", .075" &

.100” thick dimensions, or sets of "one-of-each.”

Optional pulley shims,

PART # PX-1

Includes one of each

.020”, .030”, .040”,

.050” and .100”

www.riveraprimoinc.com

6