Mittler Bros Machine & Tool 2800 72” Ultimate Box & Pan Brake User Manual

Page 6

02-08-2013 Rev 4

For the following adjustments, use test strips of metal, each approximately 3 inches by 3 inches, of

the thickness being formed.

When bending use the longer bend fingers and leaf fingers, as the material allows.

Step 1: Clamping Pressure

Check clamping pressure by clamping test strips in the brake approximately 3 or 4 inches away from

each end of the brake. Clamping pressure should be enough to keep the material from slipping during

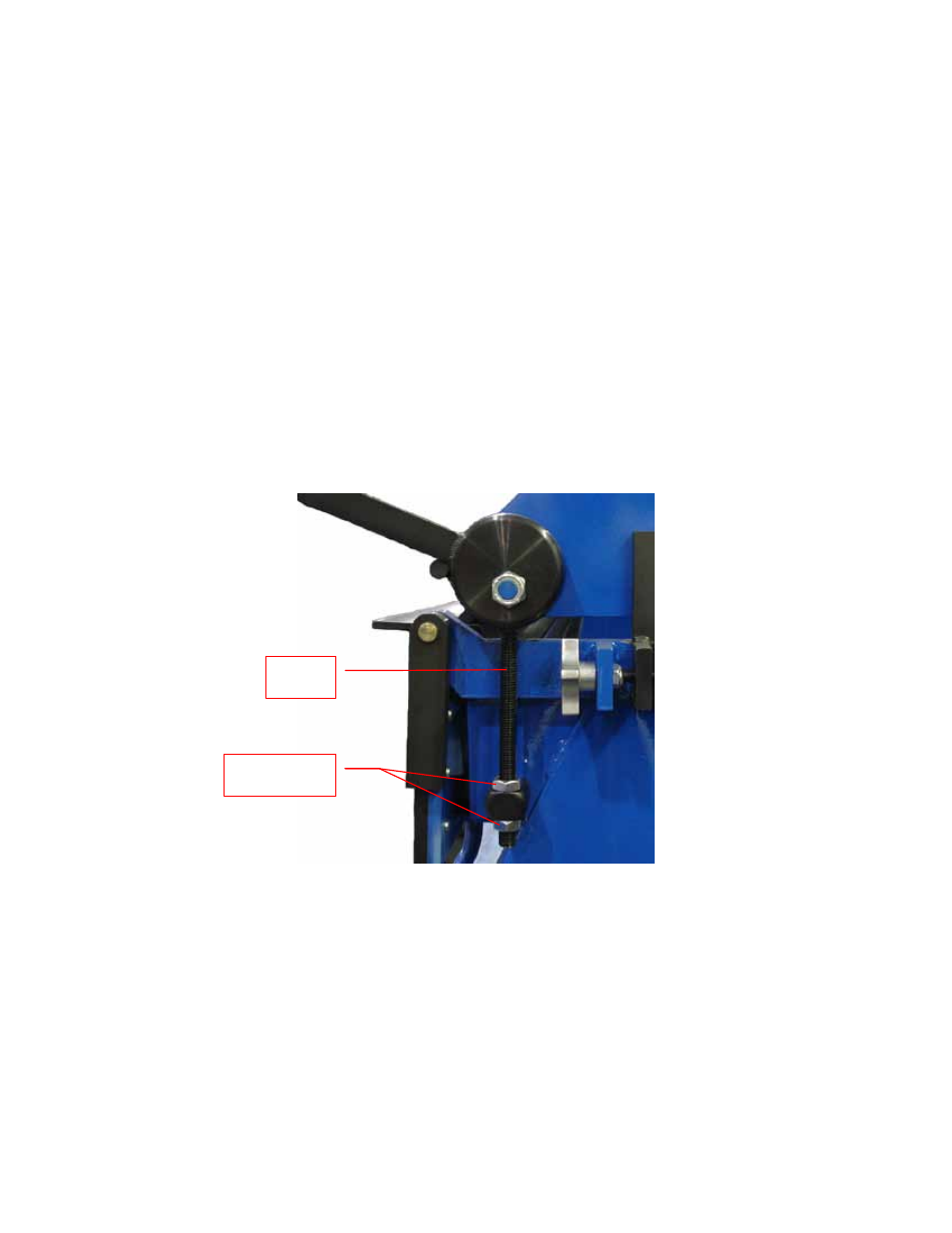

a bend. It is not desirable to use excessive clamping pressure. To change clamping pressure, locate

the stem coming from the bottom of the locking cam. There are two nuts on the stem. By loosening

the top nut and adjusting the bottom nut, clamping pressure can be increased or decreased.

Clamping pressure should be adjusted according to the thickness of the material being worked. A

common cause of bending and forming problems is excessive clamping pressure. Clamping pressure

should be adequate to hold the material securely in place but not so great as to require undue effort

in locking the clamp handles.

Stem

Lock Nuts

Lock Nuts