Model ht 3196 only, Post assembly checks – Goulds Pumps ANSI FAMILY IOM (ATEX Compliant) User Manual

Page 29

94

ANSIFAM IOM - 5/08

6.

Check total travel of impeller in casing. With new

parts, acceptable range is 0.030 in. (.76 mm). to

0.065 in. (1.65 mm). If outside this range,

improper parts or installation or too much pipe

strain is present. Determine cause and correct.

7.

Adjust impeller clearance according to procedure

outlined in the Preventive Maintenance Section.

8.

Replace auxiliary piping at this time.

9.

Fill pump with proper lubricant. Refer to

Section 5,

Preventive Maintenance for requirements.

NOTE: For reassembly of the C-Face adapter,

see Appendix V.

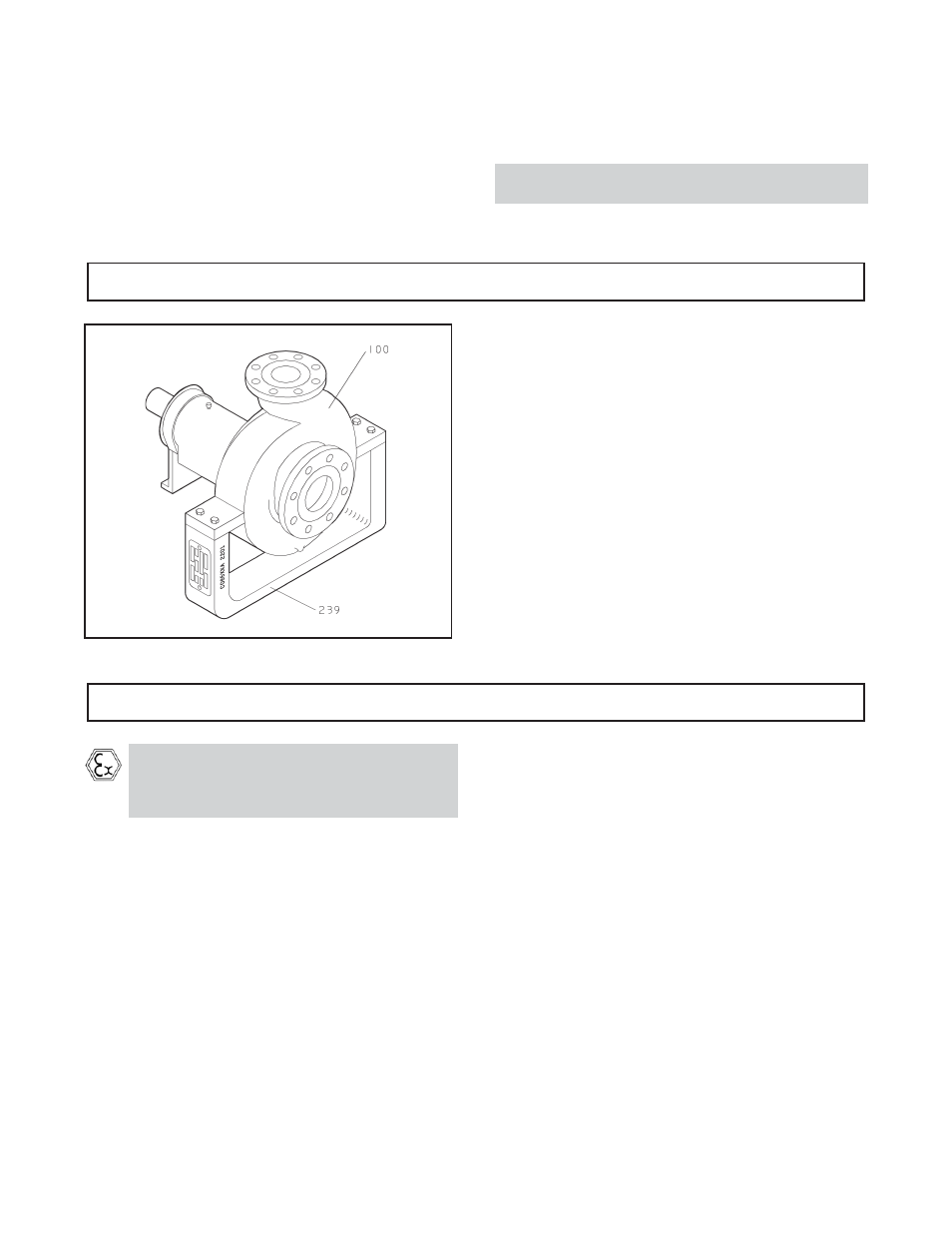

Model HT 3196 Only

1.

Assemble casing support (239) to casing (100) as

shown in Fig. 178. The stamped part number on

the casing support (239) is located on the left

hand side when facing the casing suction.

POST ASSEMBLY CHECKS

All checks and procedures listed under

Safety, Installation, Operation and

Preventive Maintenance sections must be

followed.

After completion of these operations, check if it is

possible to rotate shaft easily by hand. If all is proper,

continue with pump start-up.

Fig. 178