Xlt-x, x17, Warning – Goulds Pumps ANSI FAMILY IOM (ATEX Compliant) User Manual

Page 14

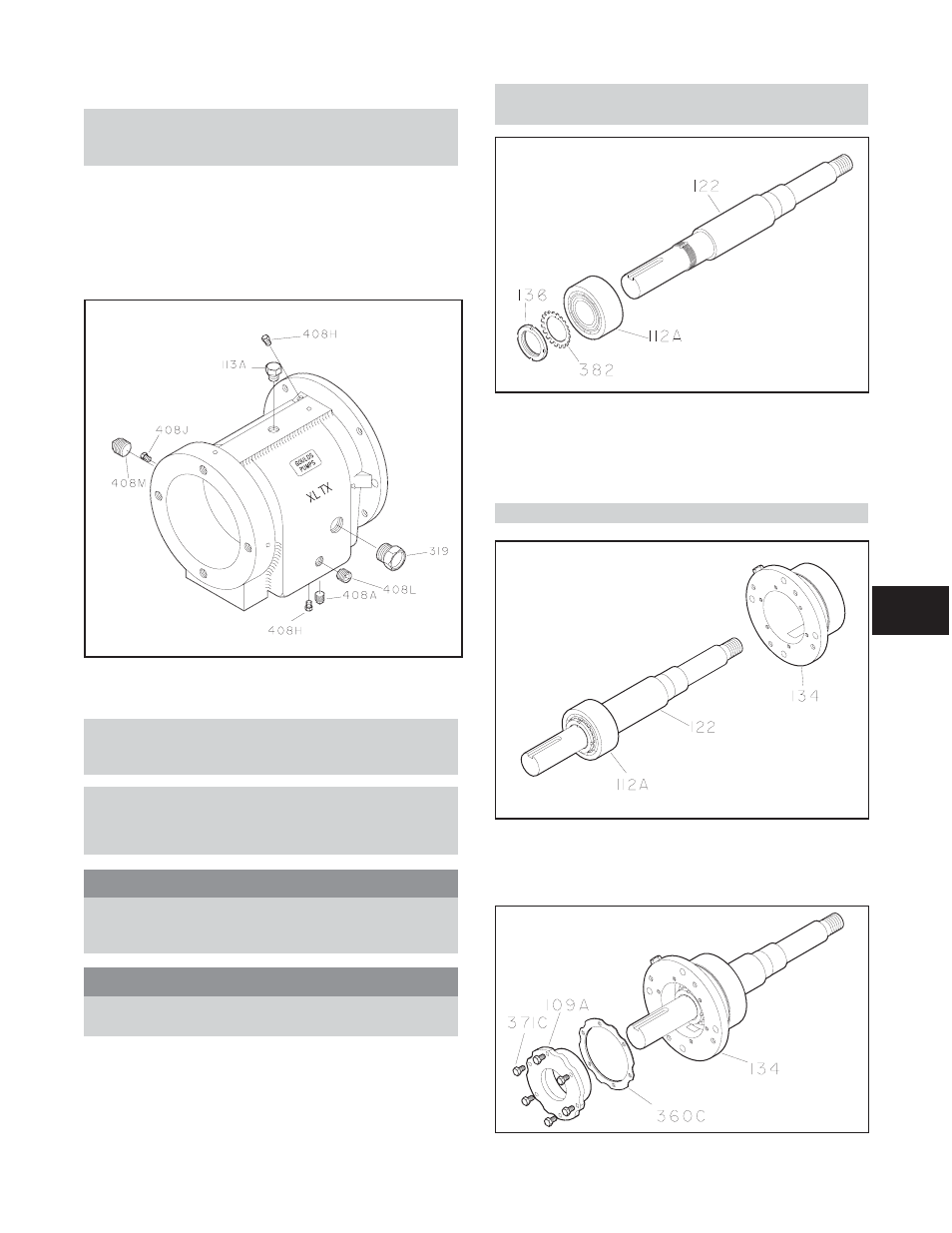

XLT-X, X17

NOTE: Make sure that threads are clean and

apply thread sealant to pipe threads and

fittings.

1.

Install oil fill plug (113A), oil drain plug (408A),

sight glass (319), sight oiler plug (408J), four oil

mist connection plugs (408H), or grease fittings

(193) and grease relief plugs (113), and oil cooler

inlet and outlet plugs or oil cooler (408L, 408M) in

bearing frame (228A) (Fig. 120).

2.

Install outboard bearing (112A) on shaft (122)

(Fig. 121).

NOTE: Regreaseable bearing has a single

shield. The outboard bearing is installed with

shield toward impeller.

NOTE: There are several methods used to

install bearings, The recommended method is

to use an induction heater that heats as well as

demagnetizes the bearings.

s

!

WARNING

Wear insulated gloves when using a bearing

heater. Bearings will get hot and can cause

physical injury.

s

!

WARNING

Shaft (122) may be heavy. Use care when

handling.

3.

Place lockwasher (382) on shaft (122). Place tang

of lockwasher in keyway of shaft.

4.

Thread locknut (136) onto shaft (122). Tighten

locknut until snug. Bend any tang of lockwasher

(382) into a slot of locknut.

NOTE: Tighten locknut if necessary to align the

closest tab of lockwasher with slot on locknut.

5.

Coat outside of outboard bearing (112A) and bore

of bearing housing (134) with oil.

6.

Install bearing housing (134) onto shaft/bearing

assembly (Fig. 122).

NOTE: Do not force assembly together.

7.

Install gasket (360C), end cover (109A), bolts

(371C). Refer to

Table 9 for bolt torque values.

Check shaft for free turning (Fig. 123).

ANSIFAM IOM - 5/08

79

6

Fig. 120

Fig. 121

Fig. 122

Fig. 123