Disassembly / reassembly, Disassembly & reassembly, Disassembly – Goulds Pumps 3498 - IOM User Manual

Page 46

DISASSEMBLY & REASSEMBLY

DISASSEMBLY. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

ASSEMBLY . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

LIMITED END FLOAT COUPLINGS . . . . . . . . . . . . . . . . . . 45

DISASSEMBLY

The numbers used in the following procedures are part

numbers identified on the Pump Assembly Pix drawing.

Use acceptable mechanical practices when working on

pump to avoid unnecessary damage to parts.

1.

Disconnect coupling. Refer to coupling manufacturer's

instructions.

2.

Drain pump by opening vent plug and removing drain

plug on discharge and suction nozzles.

3.

Remove gland bolts, slide gland plates (107) away to

disconnect mechanical seal faces.

4.

Remove all casing main joint nuts and dowels. Use

jacking screws in two tapped holes to break joint. Lift

casing cover by cast lugs.

5.

Gasket

A strong Garlock 3000 gasket is placed between the

pump half casings at the factory. The gasket may be

readily replaced, when necessary, with the same or

similar material of the same thickness as original and

cut to proper shape. Heavier gaskets must not be used,

as they hold the casing apart allowing leakage around

the wearing rings. A lighter gasket will place undue

stress on the casing rings.

6.

Remove bolting holding bearing housings caps to

bearing housings (134D). Mark the caps to know to

what end they belong. Lift up the caps. The entire

rotating element may now be lifted out.

7.

Pull coupling half and key off shaft. Remove bearing

end plate (111).

8.

Remove both casing rings (127).

9.

Remove radial bearing (168).

10. Remove locknut and lockwasher (136 & 382) and pull

off thrust bearing (410).

11. Remove bearing endplates and bearing seals (333A &

332A).

3498 IOM 12/04

43

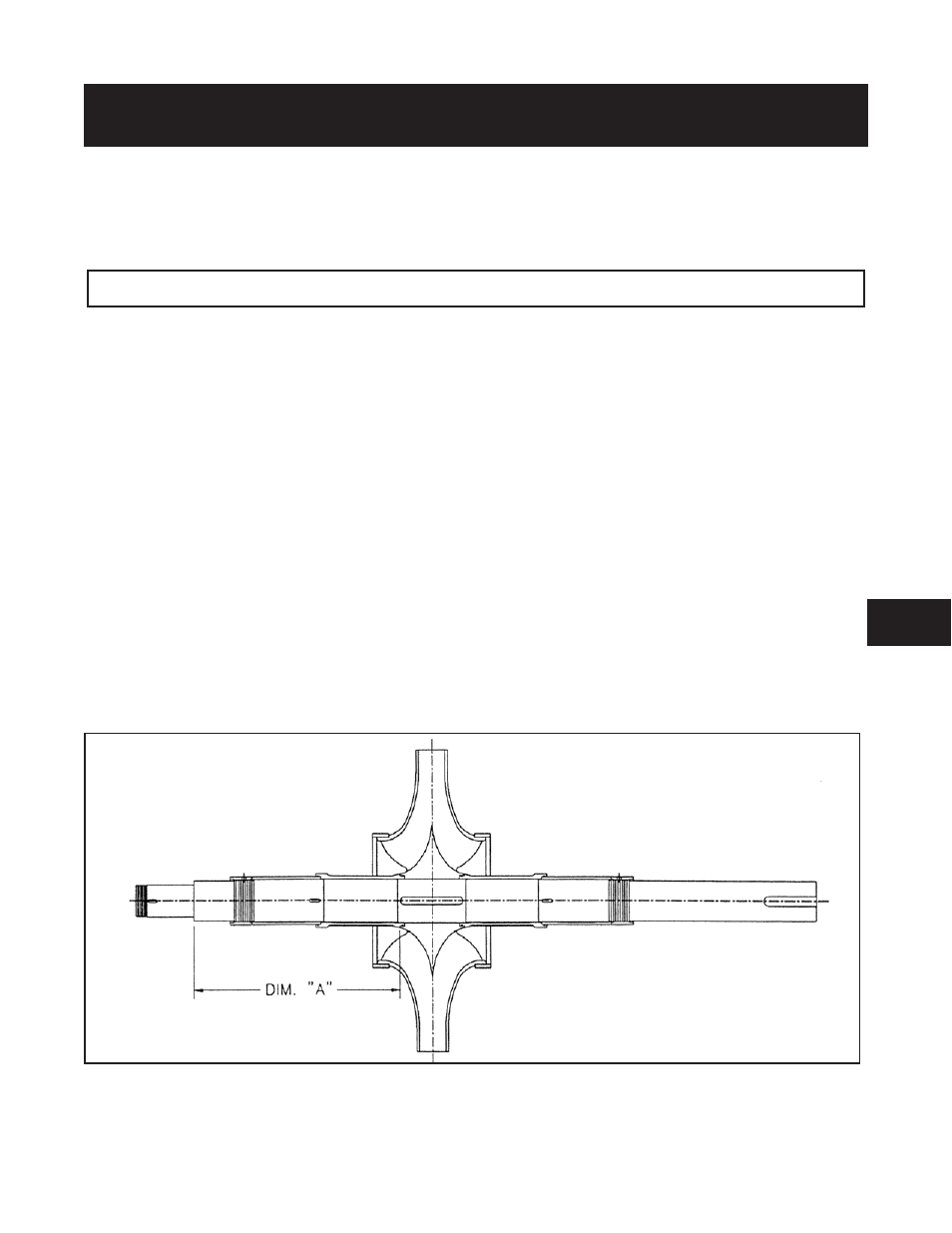

Fig. 14

6