Storage requirements, Temporary storage of equipment – Goulds Pumps 3498 - IOM User Manual

Page 20

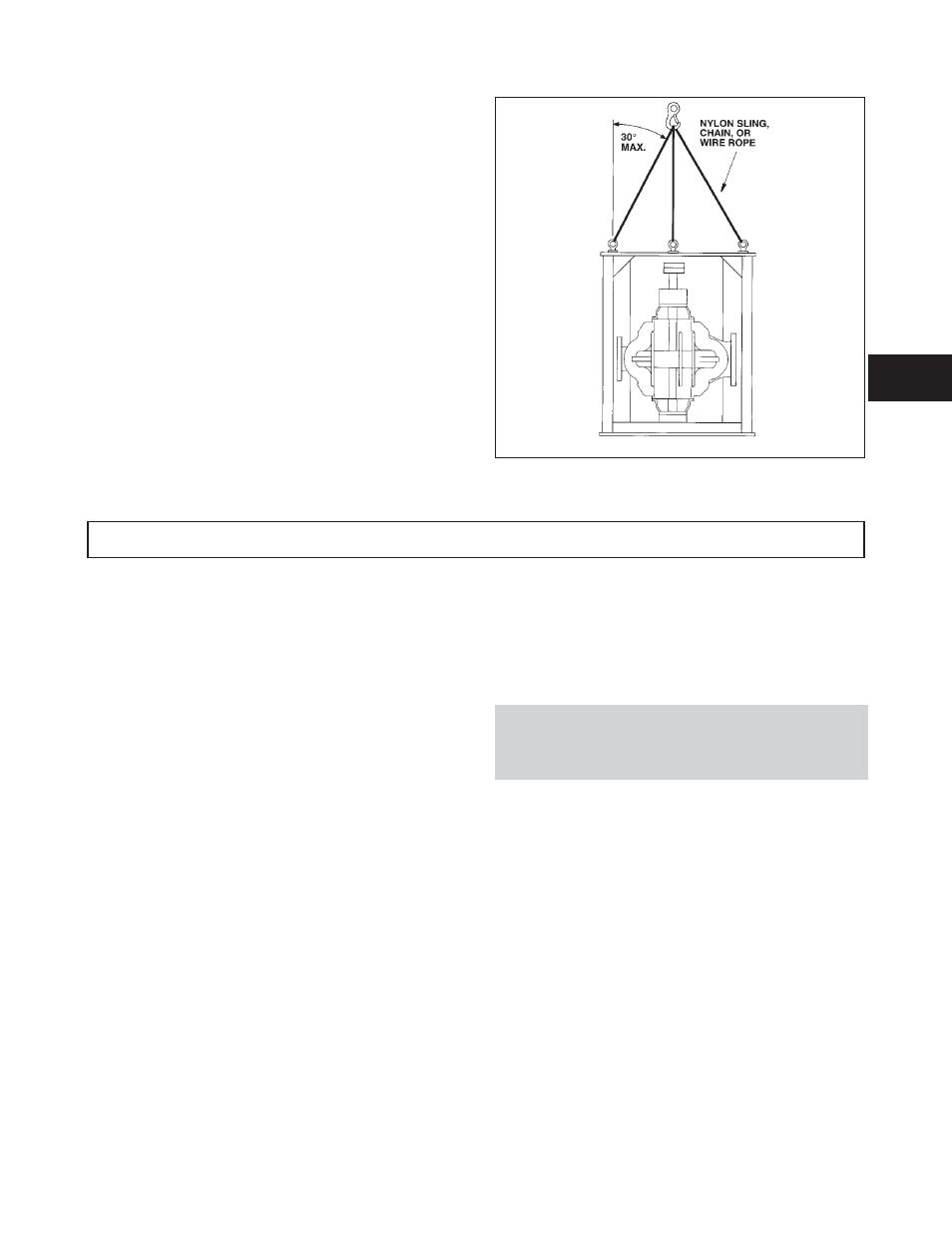

Full Pedestal

2.

Install eye bolts in the three holes provided at the top of the

support, being sure to tighten securely. Attach chain or wire

rope using latch hook or standard shackle and end loop.

Be sure to use shoulder eye bolts that are manufactured per

ANSI B18.15 and sized to fit the holes provided.

Be sure lifting equipment is of sufficient length to keep

the lift angle less than 30° from the vertical

(See Fig. 6).

STORAGE REQUIREMENTS

Consider a Unit in Storage When:

1.

It has been delivered to the job site and is awaiting

installation.

2.

It has been installed, but operation is delayed pending

completion of planned construction.

3.

There are long period (30 days) between operation cycles.

4.

The plant or department is shut down.

TEMPORARY STORAGE OF

EQUIPMENT

This procedure applies to horizontal and vertical pumps

only for storage of one month or less. For longer periods,

refer to LONG TERM STORAGE OF EQUIPMENT.

Accessories such as motors, steam turbines, gears, etc.,

must be handled in accordance with the respective

manufacturer’s recommendations.

Oil Lube Frames

Storage requirements vary depending on length of storage

and the climatic environment.

If the equipment is not to be installed and operated soon

after arrival, store in a clean, dry, well ventilated place, free

from vibration and rapid or wide variations in temperatures.

On all rotating equipment, rotate the shaft several

revolutions every week to coat the bearings with lubricant,

retard oxidation or corrosion, and prevent possible

brinelling. Shaft extensions and other exposed machine

surfaces should be coated with an easily removable rust

preventative such as Tectyl No. 502C, Valvoline Oil

Company, Division of Ashland Petroleum Company.

NOTE: Oil lubricated pumps are shipped without

lubricant. Fill the frame completely with oil for

storage. Before putting equipment into operation,

drain the oil to proper level.

Grease Lube Frames

Storage requirements vary depending on length of storage

and the climatic environment.

If the equipment is not to be installed and operated soon after

arrival, store in a clean, dry, well ventilated place, free from

vibration and rapid or wide variations in temperatures.

On all rotating equipment, rotate the shaft several

revolutions every week to coat the bearings with lubricant,

retard oxidation or corrosion, and prevent possible

brinelling. Shaft extensions and other exposed machine

surfaces should be coated with an easily removable rust

preventative such as Tectyl No. 502C, Valvoline Oil

Company, Division of Ashland Petroleum Company.

3498 IOM 12/04

17

Fig. 6

3