Caution – Goulds Pumps 3409 - IOM User Manual

Page 47

7.

Assemble casing rings (127). (See Adjustable Wear Ring

Section, if required.)

8.

Install stationary seats (383) into the glands (250) with

lapped surface facing outward.

NOTE: Do not scratch or damage seal faces during

assembly. Stationary seat must bottom squarely in

gland.

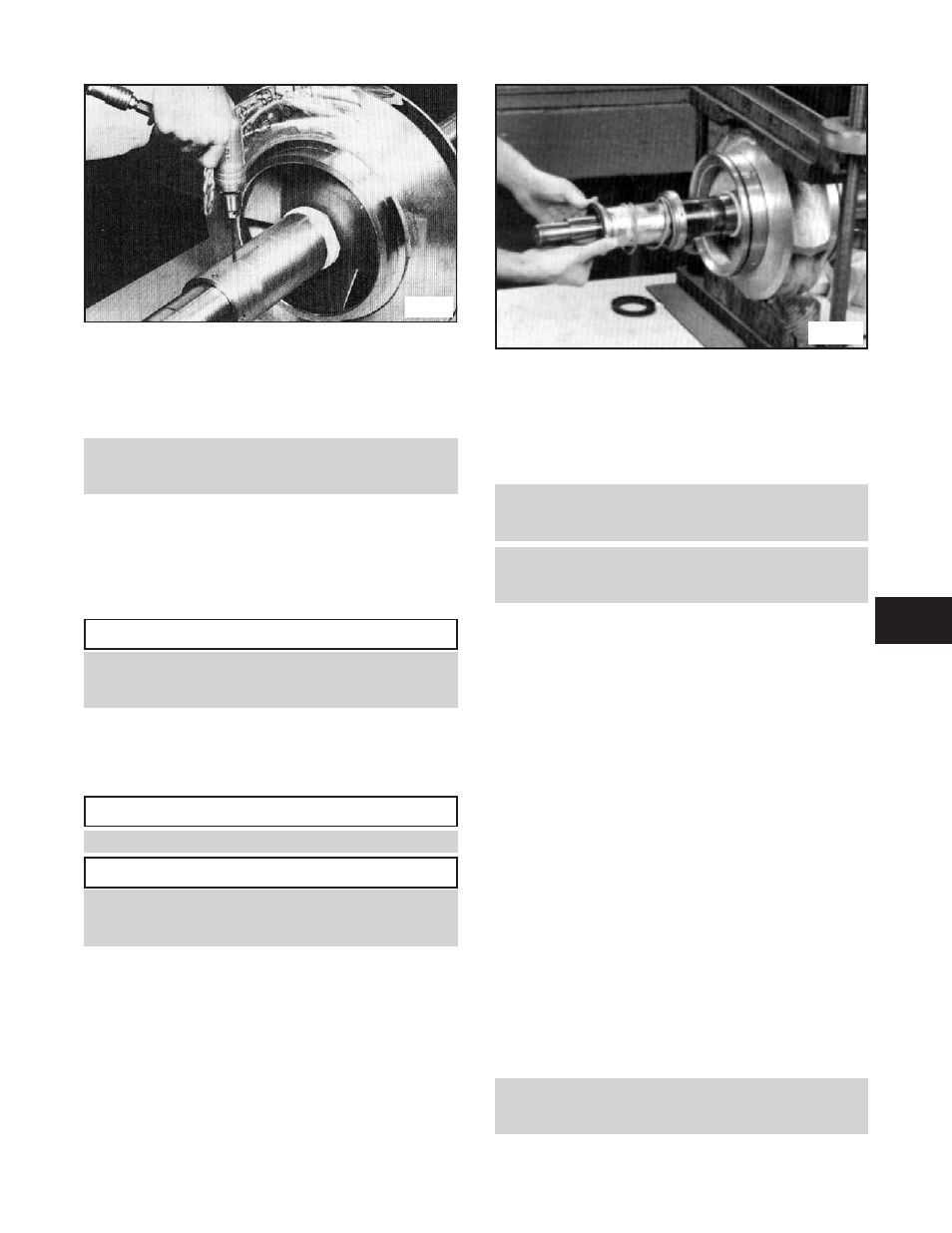

9.

Apply fine coat of silicon grease or equivalent to shaft

sleeve, and slide seal head assembly (383) over sleeve.

(See Fig. 26) If seal is a John Crane Type 8, set seal to

approximate dimension shown in Fig. 28 and tighten

set screws. Next, install O-rings (412G) onto glands

(250) and install glands on the shaft.

$

CAUTION

Do not use petroleum based products for installing

mechanical seal head as it may attack the rubber

elastomers.

10. Start heating bearings (168 & 410) so that they will be

ready when called for in step 13. Use dry heat from

induction heat lamps or electric furnace, or a 10-15%

soluble oil and water solution.

$

!

CAUTION

Do not exceed 275° F.

$

CAUTION

These are precision, high quality bearings. Exercise

care at all times to keep them clean and free of foreign

matter.

11. Press inboard bearing isolators (333A) in each bearing

cover. Install gaskets (360) on each bearing cover.

12. Slide bearing covers (109 & 119) on the shaft. Install snap

rings (276). Install thrust washer (535) on the outboard

end.

NOTE: For ease of assembly and protection of rubber

parts while sliding rubber parts onto shaft, cover O-ring

groove, keyways, and threads with electrical tape.

NOTE: Inboard bearing cover (119) is approximately 1/4

inch less in width than the outboard bearing cover (109).

This is the only dimensional difference.

13. Press heated bearing (168 & 410) on shaft against snap

ring or thrust washer. Install locknut (136) and lockwasher

(382) on outboard end. Make certain the locknut is secured

and then bend over tab on lockwasher.

PUMPS WITH GREASE LUBRICATION

14. Cool bearings at room temperature and coat with 2 or 3

ounces of a recommended grease.

PUMPS WITH OILLUBRICATION

See Oil Lubricated Bearings Section for installation of oil

lubricated parts.

15. Press outboard bearing isolator (332A) in coupling end

bearing housing.

16. Slide bearing housings (134) over bearings (168 & 410).

17. Assemble bearing cover to bearing housing with two cap

screws (371C).

18. Replace pump coupling half and key (400).

19. Assemble rotating element in lower half casing (100).

Correctly locate casing ring pins (445A) in casing main

joint slot.

NOTE: Sliding inboard bearing housing toward coupling

prior to assembling rotating element in casing will ease

assembly.

3409 IOM 11/04

47

Fig. 25

Fig. 26

6