Instructions – Quick Cable Quick Crimp Pneumatic Crimper User Manual

Page 4

4

Instructions

Using Universal Hex Dies (4255UDA & 4255UDB)

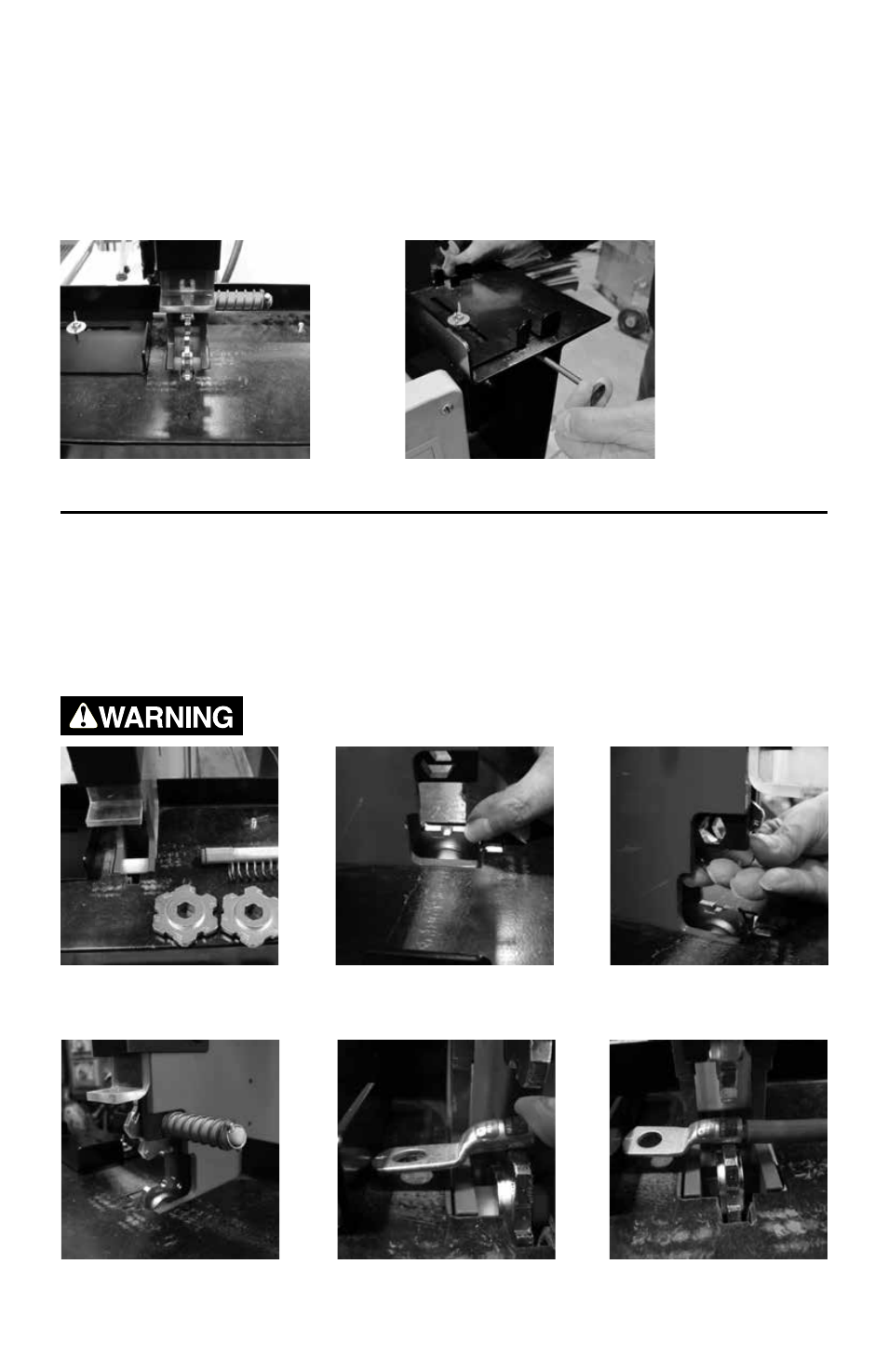

A. Adjustable guide plate on left.

B. Spring loaded upper die retainer.

1. Select the dies required to

crimp the gauge and type of

connector you want to crimp.

4. Completed die installation.

2. Install one die in lower

position.

5. Adjust guide plate so that

connector is positioned in die

set for 1st crimp.

3. Install other die in upper

position.

6. Insert cable in connector.

Spring loaded lower die retainer.

The Quick Crimp Pneumatic Crimper has an adjustable guide plate, a spring-loaded lower

die retainer, and a spring-loaded upper die retainer. The guide plate is used to position the

connector so that the crimp area is centered within the die area. The lower die retainer can be

pulled back using the knob on the left side of the machine. Die retainers have a round forward

shank and a hex toward the rear where they engage the die. Pulling back part way allows you

to rotate the die into position on the round part of the shaft, and then the hex end engages to

hold the die in place.

Our universal hex dies are used to crimp cast copper, heavy-wall copper tube and standard

copper tube lugs as well as brazed seam lugs, SB, SBX and DIN contacts. Refer to the supplied

die settings chart to identify the correct die settings for the particular gauge and type of connector

that you intend to crimp. There are four dies in the universal die set, two A dies and two B dies.

This provides die settings using two A dies, an A die and a B die, or two B dies. Once you have

determined which dies to use for the connector you want to crimp, follow these steps:

Disconnect air supply before changing dies or making adjustments.