Crimp pneumatic – Quick Cable Quick Crimp Pneumatic Crimper User Manual

Page 3

3

Extremely high operating pressures may

cause explosive failure and flying debris

You can crimp a variety of connectors

from 8 gauge to 4/0 using the Quick Crimp

Pneumatic Crimper

Maintaining the Quick

®

Crimp Pneumatic

The internal operating parts of the Quick Crimp

Pneumatic Crimper are factory lubricated and do

not require additional maintenance. A grease fitting

is supplied so you can grease the roller assembly

periodically. If you are using the B-crimp die set, the

guide pin should be lubricated with moly grease.

• Wear Safety Goggles.

• Do not operate without protective shields in place.

• Do not operate if crimping dies are worn or damaged.

• Disconnect air supply before changing dies or performing other maintenance.

• Do not allow bystanders around the machine while it is operating.

• Use caution with the foot pedal—be sure to remove your foot until you are ready to

initiate a crimp cycle. The Quick Crimp Pneumatic Crimper can develop more than 6

tons (12,000 lbs.) of force.

• Our Universal Hex Dies (part number 4255UDA & 4255UDB) can be used to crimp

cast copper connectors, heavy-wall copper tube lugs, standard copper tube lugs,

brazed seam lugs and SB, SBX and DIN contacts.

• An additional die set is available to make diamond crimps in these same connectors

(part number 4252D).

• A unique die set is required to crimp lead-free OEM style band terminals

(part number 420506).

• A special die set is also available for brazed seam flag connectors (420579).

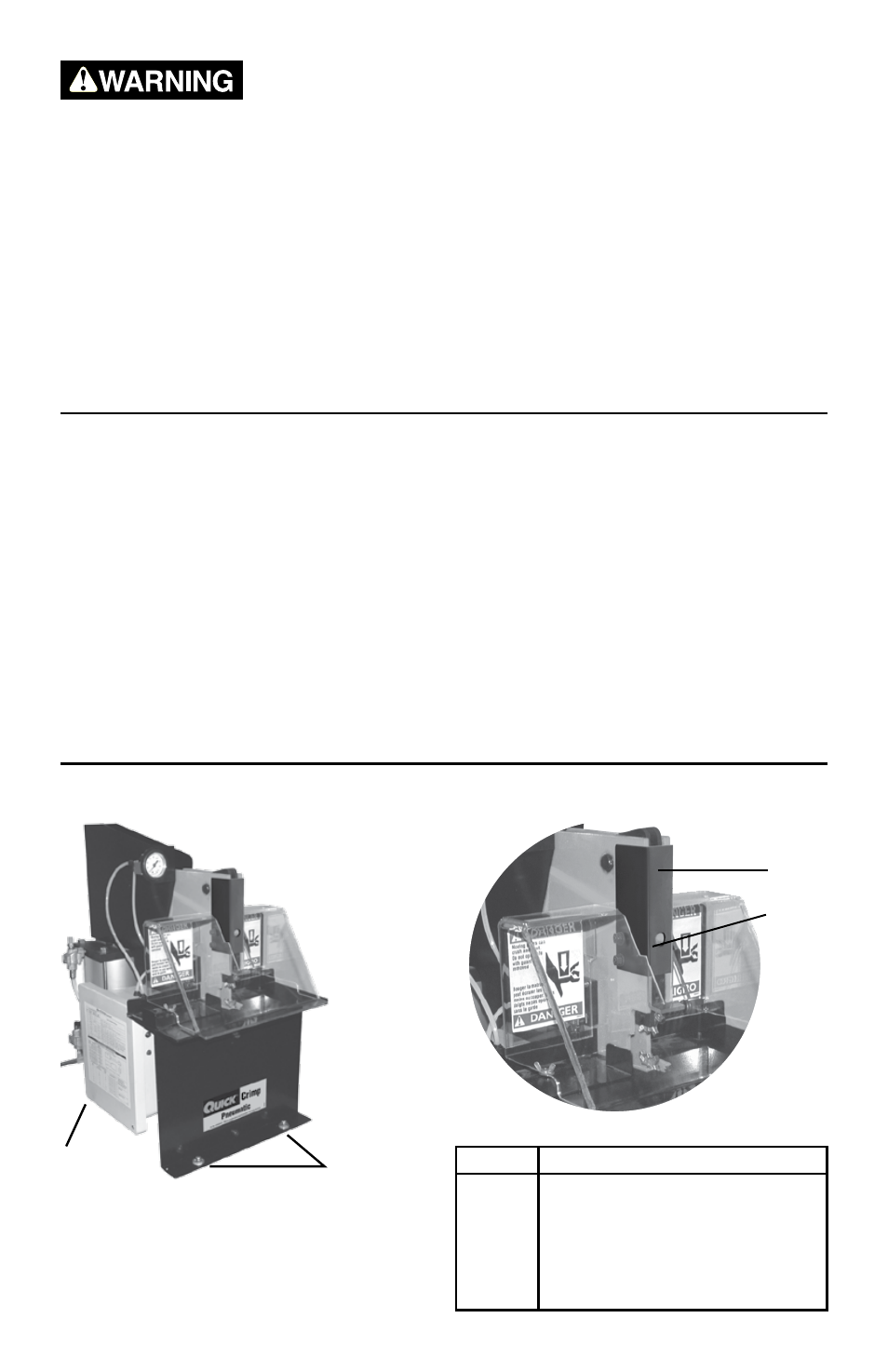

Grease

fitting

Roller

Mounting

points

Figure 1

Mounting

point

Spare Parts

420550-2

420550-3

420550-4

420550-5

420550-6

420550-7

Replacement die guard with warning labels

Replacement quick release pin with ring

Replacement upper crimp die shaft with snap ring

Replacement guide plate with nut

Replacement upper die shaft spring

Replacement filter/regulator

Part No.

Description