540r brushless motor, Motor manual, Introduction features – Team Associated APEX Touring Brushless Powered User Manual

Page 16: Precautions and warnings, Installation and maintenance, Safety precautions, Warranty, Caution, Specifications

16

:: Motor Manual

540R

BRUSHLESS

MOTOR

Introduction

Features

Congratulations on your purchase of Reedy’s

540R Brushless Motor. The latest brushless

motor technology along with the design and

engineering experience that is responsible for 28

World Championship titles has been incorporated

into its design.

Due to its sensorless design, the Reedy 540R

Brushless Motor operates powerfully and

efficiently without complicated sensor harnesses.

This motor is perfectly suited for use with ESCs

that are designed to operate sensorless

brushless motors.

Please read the following before

installing and using your new motor.

• Oversized Precision Ball Bearings

• High-Strength Rotor

• Hardened Steel Shaft

• Triple-Insulated Windings

• Sensorless Operation

• 3.5mm Connectors

Precautions and Warnings

• Please read the instructions before installing

and operating your motor.

• Avoid over gearing by monitoring motor

temperature. Operating temperatures should

not exceed 80C (175F).

• Be sure to use the proper size motor mounting

screws.

• Do not over-tighten the motor mounting screws.

• Do not use a Schottky diode with this motor.

Installation and Maintenance

• Your motor should be installed using 3mm

screws with a length (generally 6mm or less)

that does not allow the screw to extend into the

motor more than 5mm. Otherwise, the screw

can damage the motor’s internal components.

• Do not over-tighten the motor mounting screws.

Doing so may strip the mounting hole threads.

• Connect the three leads exiting the motor to the

three motor leads from your Electronic Speed

Control (ESC). If the motor runs backwards

when giving it forward throttle, reverse any two

motor leads. The motor will now turn in the

desired direction.

• To clean your motor, lightly brush dirt away on

a regular basis paying particularly close attention

to the areas around the ball bearings. DO NOT

spray cleaners or solvents into the motor.

Safety Precautions

This product is a sophisticated hobby product and

not a toy. It must be operated with caution and

common sense and requires some basic

mechanical ability. Failure to operate this product

in a safe and responsible manner could result in

injury or damage to the product or property. This

product is not intended to be used by children

without direct adult supervision. It is essential to

read and follow all instructions and warning found

in this manual prior to installation, set up, and use

in order for the product to operate properly and to

avoid damage or injury.

Warranty

Your motor is warranted to the original purchaser

for 90 days from the date of purchase, verified by

the sales receipt, against defects in material and

workmanship. Motors that have been mishandled,

abused, used incorrectly, used for an application

other than intended or damaged by the user are

not covered under warranty.

Associated Electrics Inc. is not liable for any loss

or damage, whether direct or indirect, incidental or

consequential, or from any special situation,

arising from the use, misuse, or abuse of this

product

Caution

When switching to a higher voltage battery from a

lower one (to 11.1V from 7.4V, for example), a

change in gear ratio or a lower kV motor might be

necessary. Otherwise, the motor or ESC may

overheat and sustain permanent damage. Please

visit www.reedypower.com for the latest gear ratio

suggestions for your particular motor and vehicle.

Specifications

540R 3300kV

916

2-3 LiPo, 6-8 NiMH

3300

36x46mm

3.17mm

10~40A

45A/60s

190g/6.7oz

540R 3900kV

917

2-3 LiPo, 4-8 NiMH

3900

36x46mm

3.17mm

10~45A

50A/60s

190g/6.7oz

540R 4900kV

918

2-3 LiPo, 4-8 NiMH

4900

36x46mm

3.17mm

10~50A

55A/60s

190g/6.7oz

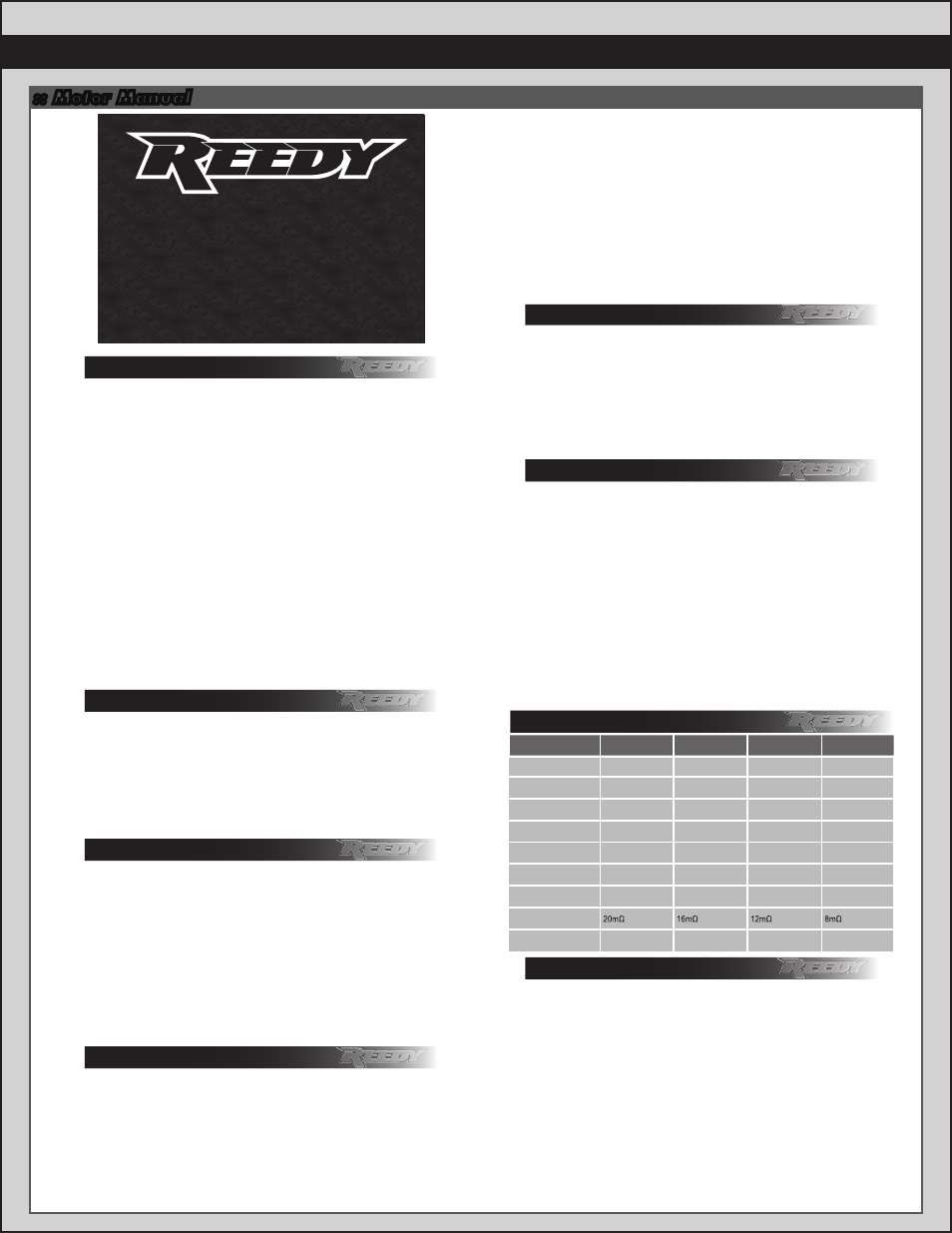

Model

Item No.

Cells

RPM/Volt

Dimensions

Shaft Diameter

Max. Efficiency Current

Max. Surge Current

Internal Resistance

Weight

540R 6100kV

919

2-3 LiPo, 4-8 NiM

6100

36x46mm

3.17mm

10~55A

60A/60s

190g/6.7oz