Maintenance & storage lubrication – Agri-Fab PRO 125 User Manual

Page 9

9

IMPORTANT: Application rates (shown on chart) are

affected by humidity and mixture content of material (granu-

lar and pellet). Minor adjustment of the flow rate setting may

be necessary to compensate for these variables. The rate

chart is calculated for light and heavy application. The faster

you walk, the wider the broadcast width. A variation in speed

will determine the flow rates and width of broadcast.

NOTE: We do not recommend the use of powdered

materials due to difficulty in obtaining a satisfactory or

consistent broadcast pattern.

TYPE

FLOW SETTING

SPREAD

MATERIAL

3 MPH

WIDTH

(100 FT. IN 17 SEC.)

IN FEET

APPLICATION CHART (SHIELD DOWN)

FERTILIZER

Powder

1 - 3

3 - 4

Granular

1 - 3

3 - 4

Pelleted

1 - 3

3 - 4

Organic

3 - 4

3 - 4

GRASS SEED

Fine

1 - 3

3 - 4

Coarse

2 - 3

3 - 4

ICE MELTER

2 - 4

3 - 4

TYPE

FLOW SETTING

SPREAD

MATERIAL

3 MPH

WIDTH

(100 FT. IN 23 SEC.)

IN FEET

APPLICATION CHART (SHIELD UP)

FERTILIZER

Powder

3 - 5

3 - 4

Granular

3 - 5

8 - 10

Pelleted

3 - 5

10 - 12

Organic

6 - 8

6 - 8

GRASS SEED

Fine

3 - 4

6 - 7

Coarse

4 - 5

8 - 9

ICE MELTER

6 - 8

10 - 12

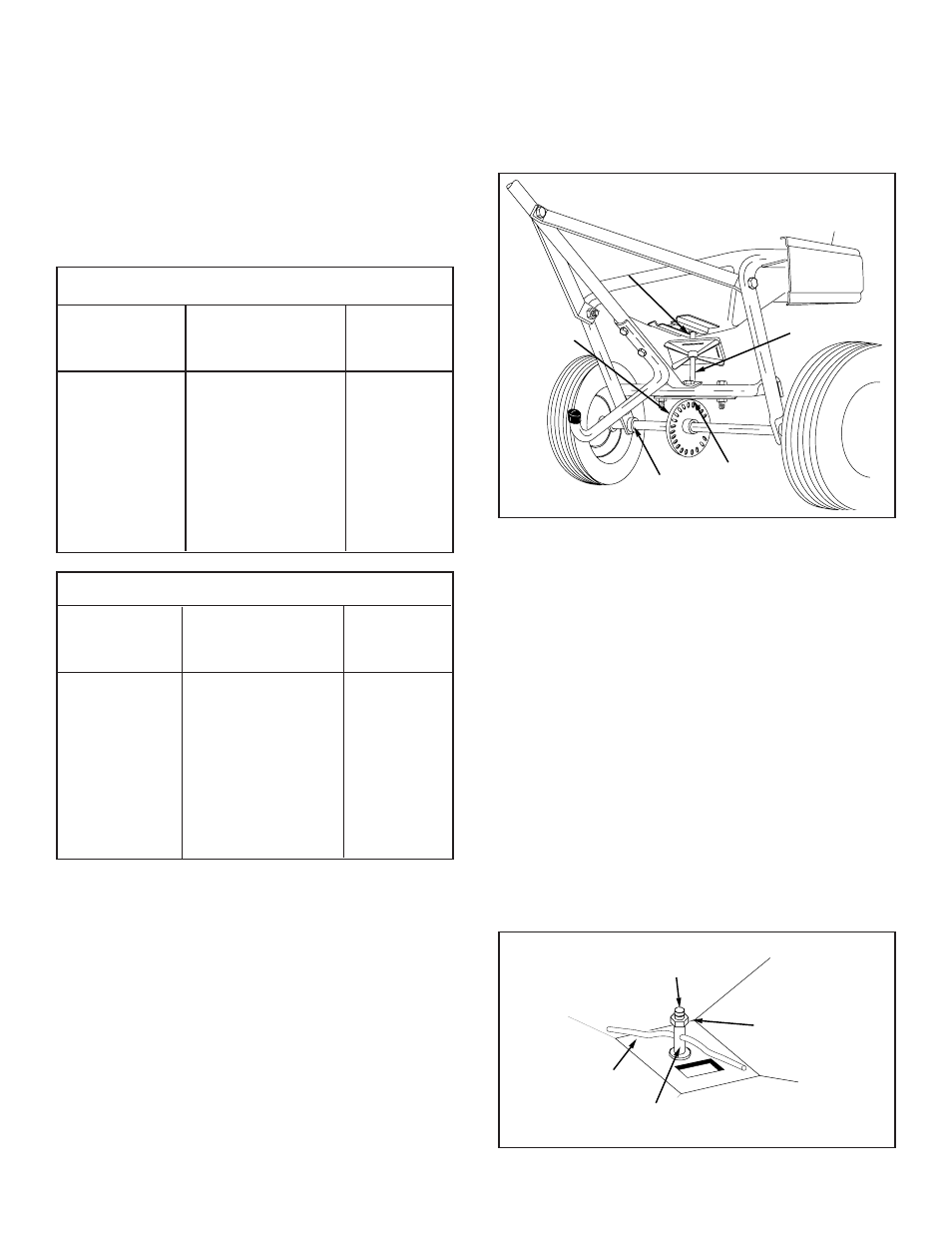

1. Apply a little automotive grease to the sprocket and gear.

2. Oil nylon bushings on sprocket shaft. See figure 17.

3. Oil axle/shaft bushing on axle as shown in figure 17.

4. Oil right hand wheel bearing as needed.

FIGURE 18

1. Do not store spreader with any material in hopper.

2. Clean your spreader after use. Flush thoroughly with

water.

3. If for any reason the axle, gear and sprocket assembly

is disassembled, be sure to mark position of parts as

they are removed. Drive wheel and sprocket position

determine relation direction of spreader plate. With

reassembly of gear and sprocket use shim washers as

needed for minimum backlash. Add grease to gear and

sprocket.

4. If agitator wire becomes damaged or worn it can be

replaced. Loosen 3/8" hex nut at top end of sprocket

shaft until agitator wire is free. Remove old agitator wire

from hole in agitator sleeve and replace with new agita-

tor wire. Position agitator wire so that sprocket shaft

turns freely and tighten 3/8" hex nut on top of sprocket

shaft. See figure 18.

MAINTENANCE & STORAGE

LUBRICATION

FIGURE 17

SPROCKET

SHAFT

AGITATOR

WIRE

3/8" HEX NUT

AGITATOR

SLEEVE

GREASE

OIL

OIL

OIL

SPROCKET

SHAFT