Glycerin well assembly, Operation – Nor-Lake Large Capacity Incubator User Manual

Page 3

RS485 port - (Optional) terminal board for RS485 port is located behind the cabinet façade, next to

the Remote Alarm access box, connect wires as per label.

Duplex, or European Outlet 4 Amp Max. – (Optional) is located near the back of the left hand

interior wall, 20” from the cabinet interior floor. Outlet is wired thru main cabinet power supply, and

includes a 4 amp, MANUAL RESET, circuit breaker. Breaker is located behind façade, on the side

of the control box.

Access Port - (Optional) 2” port is provided with a spring loaded, exterior cover, RH or LH side of

the cabinet.

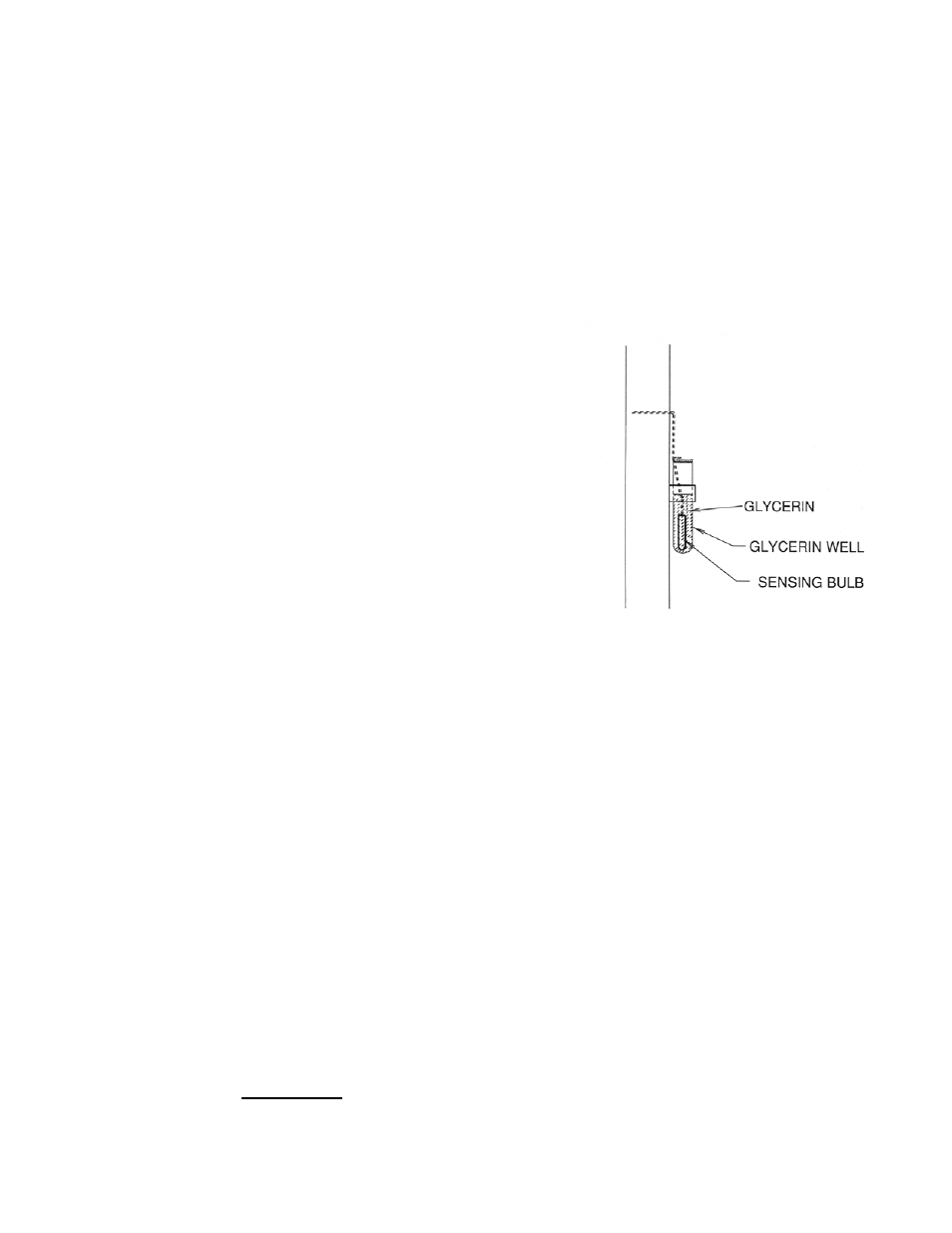

GLYCERIN WELL ASSEMBLY

3

7/10 Rev. C 131783

Important: For accurate product temperature reading, the

product-sensing bulb must be immersed in glycerin solution

contained in the provided well.

One glycerin well is furnished with each model. The

purpose of the glycerin is to simulate the product stored in

the Incubator. The glycerin temperature reflects the

product's temperature during normal operation.

Figure 1

After the unit is put into operation, check to make sure that

the temperature indicating or alarm sensing bulb is

positioned inside the glycerin well as far as possible without

touching the well itself.

OPERATION

The Large Capacity Incubator is designed for an operating range of 5°C above room ambient to

70°C and is intended for indoor use only. A transverse blower optimizes airflow and ensures tight

temperature uniformity.

These units employ a programmable controller to control the temperature and CO

2

option. The

controller is located on the facade of the unit. Please see the separate instructions, part number

113635, on the operation of the controller used in the Large Capacity Incubator.

The Incubator utilizes an electrically operated heater to warm the cabinet. The programmable

control is factory set with a cutout temperature of 70°C (158°F) to prevent the cabinet from

exceeding its design limitations.

NOTE: The cabinet is equipped with two switches located on the façade. One is the main power

ON/OFF switch for the unit. The other is a three-position switch for the battery-powered alarm. The

alarm switch is placed in the middle, or OFF position, for shipment. When the Large Capacity

Incubator is put into operation, the top of the switch should be pushed in to the ON position. With

the switch in the ON position, the battery will sound the alarm if the main power to the cabinet is

interrupted. The switch flipped to the bottom position is used to test the battery. This test must be

done with power uninterrupted to the cabinet. The alarm will sound if the battery is good. This test

should be done periodically. The battery is located on the control box that is on top of the unit

behind the façade.