Specifications, Troubleshooting – Nor-Lake AdvantEDGE Direct Draw Beer Coolers User Manual

Page 3

09/13 Rev. H 143596

3

Condenser Coil

Prior to cleaning the condenser coil disconnect the unit from power. Periodic cleaning

of the condenser coil will aid the heat transfer of the refrigeration system and increase

its efficiency. To accomplish this, remove the lower front grill from the cabinet. The

condenser coil is located behind the grill. Use a soft bristled brush to remove any dirt

particles that are on the fins of the condenser coil. Use a vacuum cleaner or

compressed air to remove the loosened particles. Replace the front grill and reconnect

the unit to power. Failure to clean the condenser coil can lead to performance loss and

compressor failure.

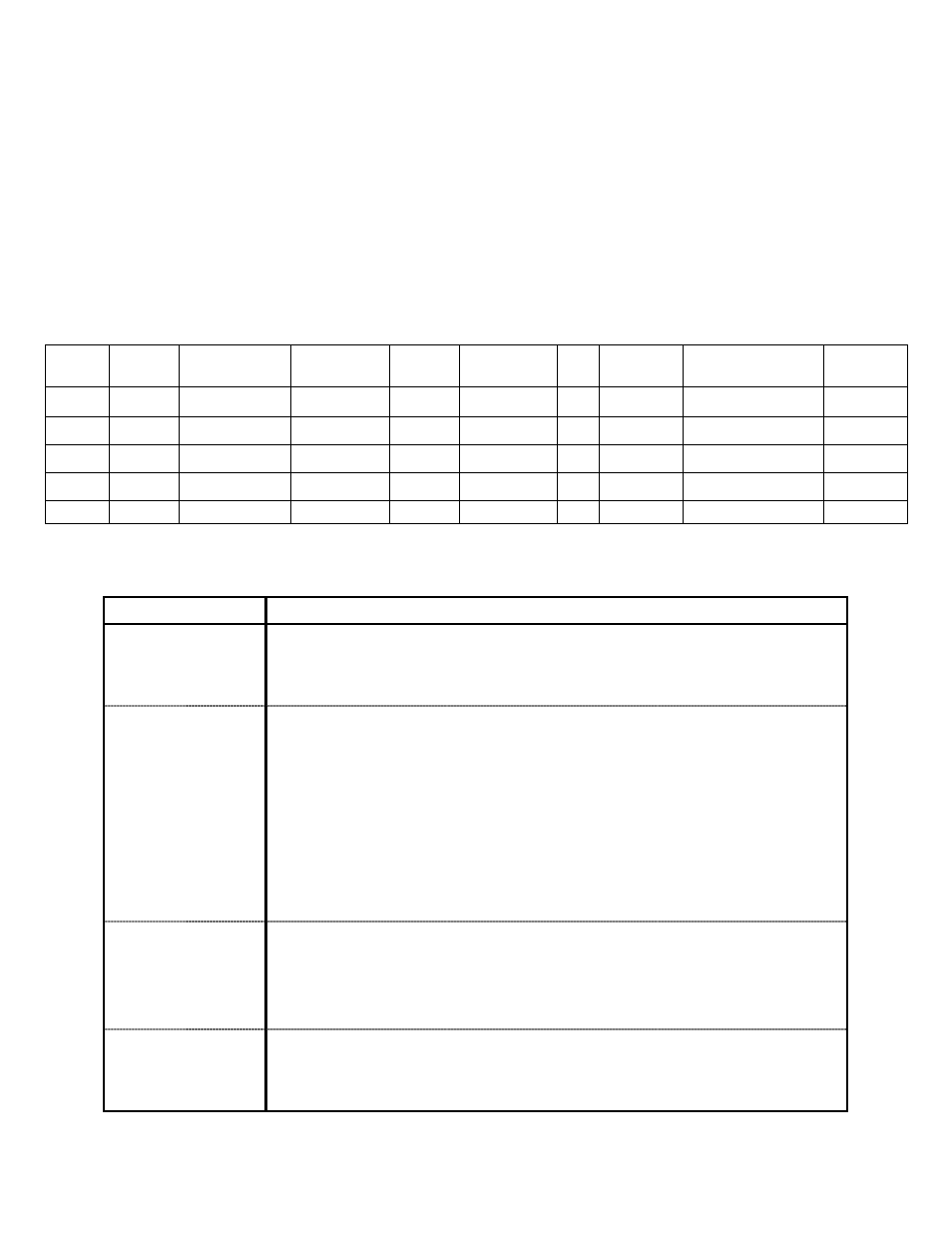

SPECIFICATIONS*

TROUBLESHOOTING

Problem

Remedy

Compressor will

not start

· Check the power cord and make sure it is plugged in and has power.

· Check the temperature controller. If it is in the “OFF” position, turn it clockwise to

set a desired temperature.

Poor performance

· Move the unit from direct sunlight.

· Move the unit away from heating devices.

· Install the unit in a well ventilated place,

with at least 2 inches of clearance on all sides.

· Clean the condenser if heavy dust is collected.

· Clear contents from blocking the inside air duct.

· Check the temperature controller for correct setting.

· Check the doors and be sure they are completely closed.

Unit noisy

· Install the unit on a level solid surface.

· Maintain 2 inches of clearance from the wall.

· Check for loose parts or mounting.

· Keep the tubing free from any contact to avoid rattle.

Condensation on

cabinet exterior

and/or floor

· Reduce humidity where the unit is installed.

·Check the drain line to make sure it is not disconnected inside the cabinet and it

drains into the drain pan in the compressor area.

Model

Doors

# of Towers /

Taps

Electrical

Amps

NEMA

Plug

HP

BTU

Capacity

Refrigerant

Keg

Capacity

DD24

1

1/1

115/60/1

2.5

5-15P

1/6

980

R-134a - 5.6 oz.

1

DD59

2

2/2

115/60/1

6.6

5-15P

1/3

1666

R-134a – 9.8 oz.

3

DD69

2

2/2

115/60/1

6.6

5-15P

1/3

1666

R-134a - 9.8 oz.

3

DD79

3

2/3

115/60/1

6.6

5-15P

1/3

1666

R-134a - 9.8 oz.

4

DD95

3

2/4

115/60/1

7.2

5-15P

1/3

1666

R-134a - 9.8 oz.

5