Nor-Lake Ice Cream Dipping-Display Merchandisers User Manual

Page 5

5

INSTALLATION INSTRUCTIONS

GENERAL INSTRUCTIONS

1. Be sure the equipment is properly installed by competent service people.

2. Keep the equipment clean and sanitary so it will meet your local sanitation codes.

3. Rotate your stock so that older stock does not accumulate. This is especially important for ice cream. A

"First-In, First-Out" rotation practice will keep the products in good salable condition.

4. Do not place product in the case when it is soft or partially thawed. Also, product should not be put in the

case for at least 6 hours after it is started.

5. Stock cases as quickly as possible, exposing only small quantities to store temperatures for short periods

of time.

6. When replacing burned out fluorescent tubes, be sure that the electrical power to the lighting circuit is

turned off.

NOTICE TO STORE OWNERS / MANAGERS

Moisture or liquid around or under the cabinet is a potential slip/fall hazard for persons walking by or

working in the general area of the cabinet. Any cabinet malfunction or housekeeping problem that creates

a slip/fall hazard around or under the cabinet should be corrected immediately.

If moisture or liquid is observed around or under a Ice Cream Dipping cabinet, an immediate investigation should

be made by qualified personnel to determine the source of the moisture or liquid. The investigation should

determine if the cabinet is malfunctioning or if there is a drainpipe leaking.

ELECTRICAL

WARNING

Before servicing electrical components in the case, make sure all power to case is off. Always use a

qualified technician.

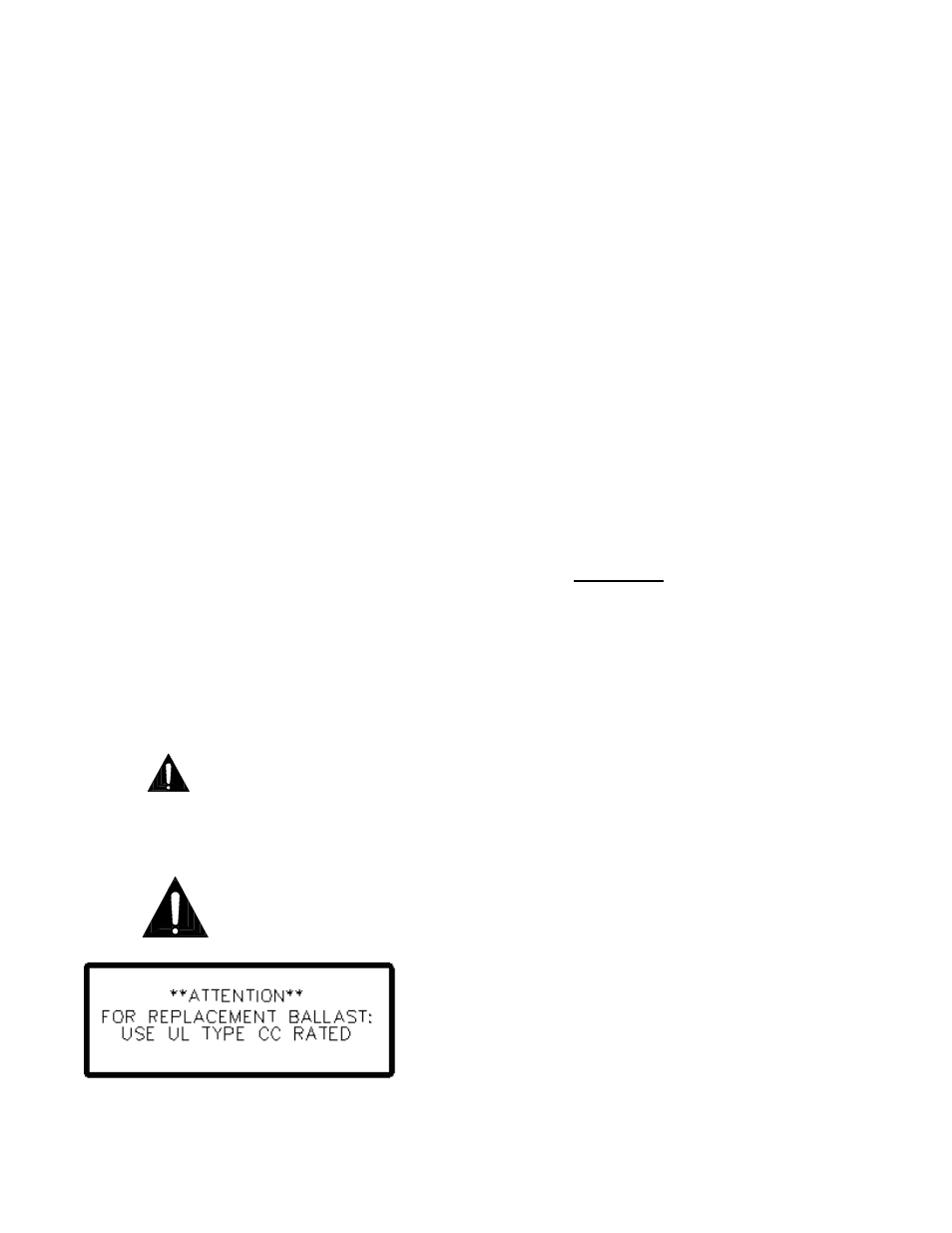

NOTICE

For mode

ls with electronic ballast only: