See attachment – Ariens 926502 - PB936 User Manual

Page 16

GB - 16

d.Finger tighten the jam nut, and then hold the

adjuster body with pliers and tighten the jam nut

with wrench.

6. Measure the extension of the traction drive clutch

spring.

7. Repeat step 5 until traction drive clutch spring

lengthens 1/2 -11/16 in.(12.7-17.5 mm) when the

traction drive clutch lever is engaged.

8. With the clutch disengaged, check that there is

more than 1/32 in. (0.8 mm) clearance between

friction disc and drive plate assembly.

IMPORTANT: If spring length cannot be adjusted

within specified range, see your Dealer for repairs.

ATTACHMENT DRIVE BELT

REPLACEMENT

Remove old attachment drive belt:

IMPORTANT: To avoid bending bottom cover when

tipping unit apart, support handlebars firmly and

remove bottom cover by removing six cap screws

before separating unit.

1. Follow the instructions for removing the brush

attachment from the unit frame under Service

Position.

2. Remove attachment drive belt from engine

sheave (it may be necessary to turn engine

sheave using recoil starter handle).

Install new attachment drive belt:

1. Place new attachment belt onto attachment

pulley.

NOTE: Holding down the attachment clutch lever will

make it easier to reconnect the housing and frame.

2. Tip attachment and frame back together and

secure with cap screws.

3. Place belt onto engine sheave.

4. Reposition and secure belt fingers.

IMPORTANT: Make sure belt fingers are 1/16 to 1/8 in

(1.6-3 mm) from belt when attachment clutch is

engaged.

5. Check clutch adjustment (see Attachment Clutch

Adjustment).

6. Replace belt cover.

TRACTION DRIVE BELT REPLACEMENT

IMPORTANT: To avoid bending bottom cover when

tipping unit apart, support handlebars firmly and

remove bottom cover by removing six cap screws

before separating unit.

1. Follow the instructions for removing the brush

attachment from the unit frame under Service

Position.

2. Remove attachment drive belt (see Attachment

Drive Belt Replacement on page 16).

3. To gain belt clearance, back out the stop bolt from

the frame until the drive plate assembly can

swing past it (Figure 16).

4. Pull idler away from traction drive belt and

remove belt from idler pulley, engine sheave and

driven pulley (it may be necessary to turn engine

pulley using recoil handle).

5. Install new traction drive belt onto attachment

pulley and engine sheaves.

6. Pull the drive plate assembly toward the friction

disc and tighten the stop bolt.

NOTE: Make sure the drive plate assembly return

spring remains connected to the frame.

7. Replace attachment drive belt (See Replace

Attachment Drive Belt).

FRICTION DISC REPLACEMENT

1. Place unit into service position.

2. Remove bottom cover by removing six hex bolts.

3. With axle locked, hold one wheel so friction disc

will not rotate and remove three cap screws

holding friction disc to carrier.

4. Remove both wheels.

5. Remove right and left bearing flanges from frame.

6. Slide hex shaft to the left enough to remove

pinion sprocket from hex shaft.

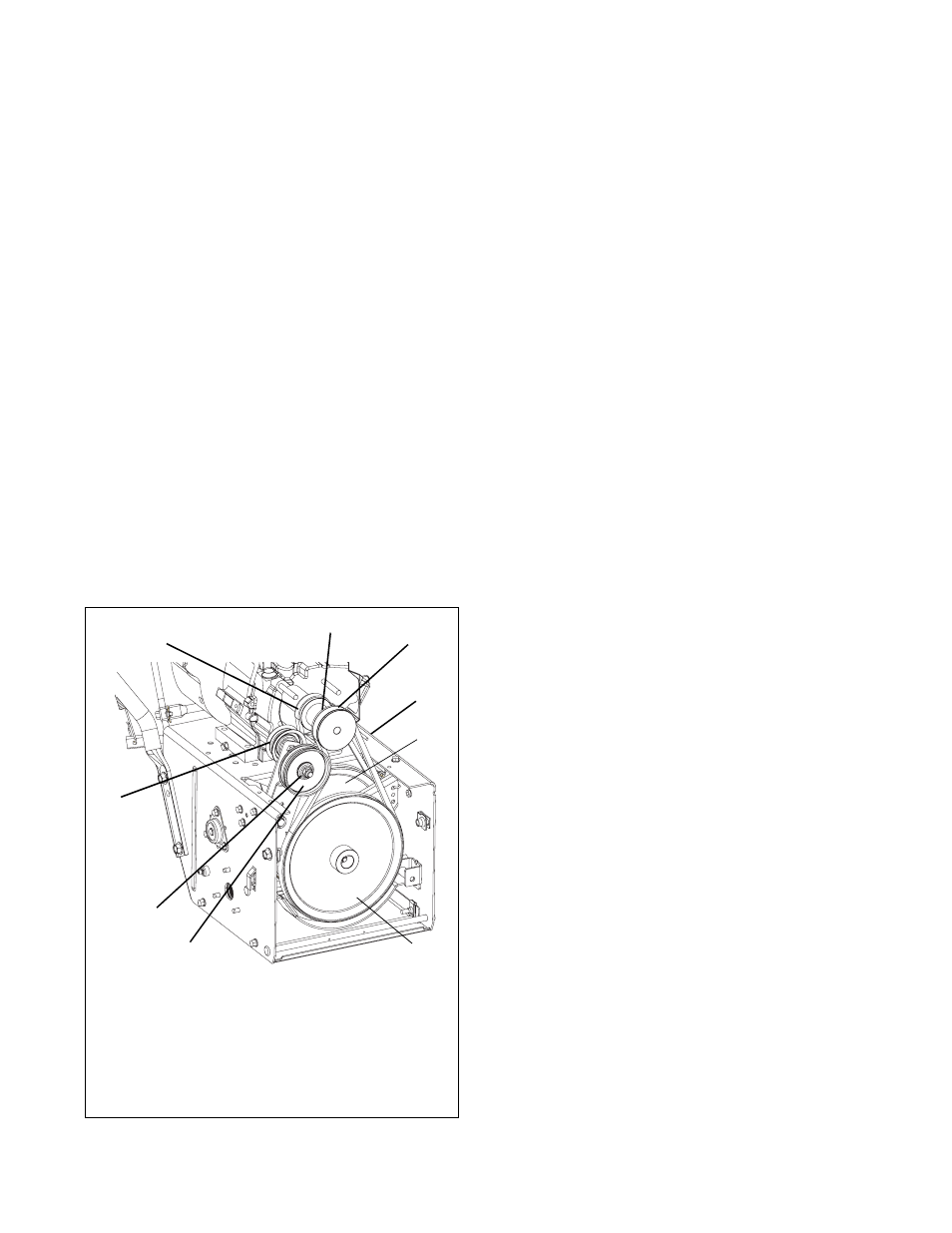

Figure 15

1. Traction Drive Belt

2. Engine Sheave

3. Attachment Drive Belt

4. Belt Finger

5. Attachment Belt Idler

6. Attachment Pulley

7. Attachment Idler

Adjustment Nut

8. Traction Belt Idler

9. Traction Drive Pulley

OS3320

1

2

3

4

5

8

9

6

7