Troubleshooting – Blodgett KLS-DS Series User Manual

Page 14

12

OM-KPS/KLS-DS

Troubleshooting

Your kettle will operate smoothly and efficiently if properly maintained. However, the following is a list of checks to make in the event

of a problem. If the actions suggested do not solve the problem, call your qualified Service Representative. If an item on the list is

followed by * , the work should be done by a qualified service representative.

USE OF ANY REPLACEMENT PARTS OTHER THAN THOSE SUPPLIED BY THE MANUFACTURER AND/OR AUTHORIZED

DISTRIBUTOR CAN CAUSE INJURY TO THE OPERATOR AND DAMAGE TO THE EQUIPMENT AND WILL VOID ALL WARRANTIES.

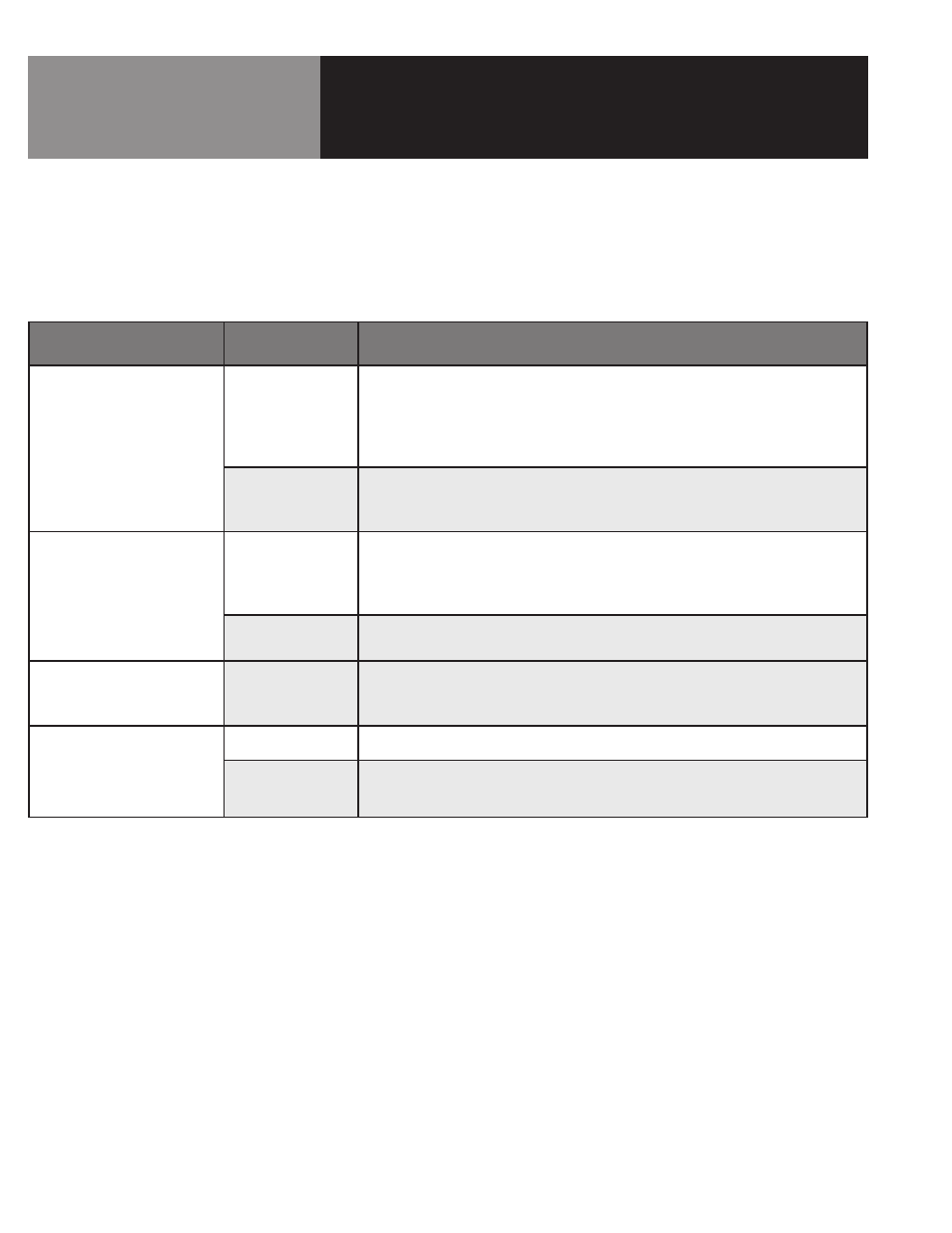

SYMPTOM

WHO

WHAT TO CHECK

(* indicates work that should only be performed by a qualified service representative)

Kettle will not heat.

User

a. That the steam inlet valve is open.

b. That the steam supply line is turned on.

c. That the condensate return valve is open.

d. That the boiler is operating properly. Steam should be

supplied at a pressure greater than five PSI.

Authorized

Service Rep Only

e. Steam supply line for blockage.*

f. Condensate return line for blockage.*

g. Steam trap operation.*

Safety valve leaks a

small amount of steam.

User

a. For contamination that prevents seating the valve. With

substantial pressure in the jacket, lift the valve lever briefly

all the way up, to blow the valve clean then let it snap back

down to seat the valve.

Authorized

Service Rep Only

b. Safety valve for defects. Defective valve MUST be replaced

with a valve rated at the same pressures.*

Safety valve leaks a

large amount of steam.

Authorized

Service Rep Only

a. Steam supply pressure.*

b. Safety valve for defects. Defective valve MUST be replaced

with a valve rated at the same pressures.*

Pipe fitting leaks.

User

a. Is the fitting tight?

Authorized

Service Rep Only

b. If tightening the packing gland does not stop the leak,

replace the packing.*