Transaxle troubleshooting – Wesley PC-325-6SA User Manual

Page 39

39

Owner’s Manual and Service Guide – PMT Series

TRANSAXLE TROUBLESHOOTING

PROBLEM DIAGNOSIS

Most drive axle problems fall into the categories of noise, vibration, leaks and failure to transmit power.

Problem diagnosis normally begins with the customer’s complaint, which should include an exact description of the type of

noise or vibration and when it occurs. This is followed up by a road test over various types of road surfaces through the speeds

where the complaint occurs.

It should be remembered that some sounds will appear to come from locations other than the real source of the problem.

Sounds in the drive shaft, exhaust system, and body floor pan can do this, making it more difficult to locate the problem source.

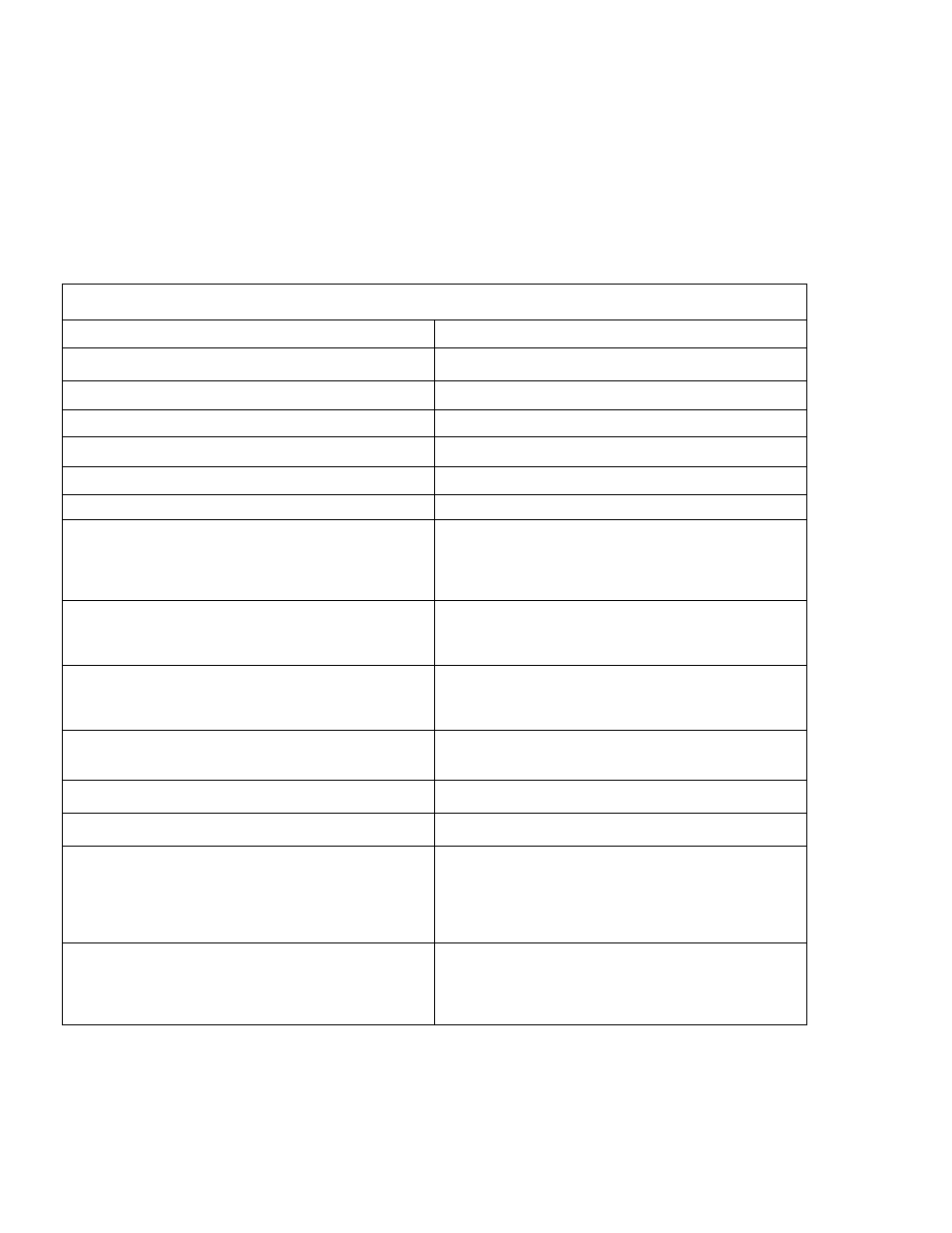

Condition Probable Cause

Noise in all driving modes

Road and tires, wheel bearings

Noise changes with type of road surface

Road and tires

Noise tone towers with car speed

Tires

Noise louder on turns

Differential pinion and side gears, axle wheel bearings

Noise in one or more driving modes

Ring and pinion gears

Clunk on change of speed or direction of power flow

Worn differential shaft or thrust washers; worn U-joints

Wheel noise

Wheel loose; faulty or bad wheel bearing

Vibration

Damaged drive shaft, missing drive shaft balance weight,

worn or out-of-balance wheels, loose wheel lug nuts,

worn U-joints, loose spring U-bolts, loose/broken spring,

damaged axle shaft bearings, loose pinion gear nut,

excessive pinion yoke run-out, bent axle shaft

Differential gears scored

Insufficient lubrication, improper grade of lubricant,

lubricant contamination, excessive spinning of wheels

Loss of lubricant

Lubricant level too high, worn axle shaft seals, cracked

differential housing, worn drive pinion gear shaft seal,

scored and worn yoke, axle cover not properly sealed,

plugged vent or vent tube.

Axle overheating

Lubricant level to low, incorrect grade of lubricant,

contaminated lubricant, bearing preload too high,

excessive gear wear, insufficient ring gear backlash

Gear teeth broke

Overloading, erratic clutch operation, wheel spinning,

improper adjustment

Axle gear noise

Insufficient lubricant, incorrect backlash, improper tooth

contact, worn/damaged gears

Axle noise

Insufficient lubricant, improper ring gear and drive pinion

gear adjustment, unmatched ring gear and drive pinion

gear, worn teeth on ring gear or drive pinion gear, loose

drive pinion gear shaft bearings, loose differential

bearings, misalign ring and pinion gear, loose differential

bearing crap-screws, worn bearings

Limited slip differential

The most common problem is a “chatter” noise when

turning corners. The probable cause is incorrect or

contaminated lubricant, or lack of “friction modifier”

additive in the lubricant. Worn or damaged plates and

discs; plates and discs improperly assembled.