Campbell Scientific CS110 Overview User Manual

Page 4

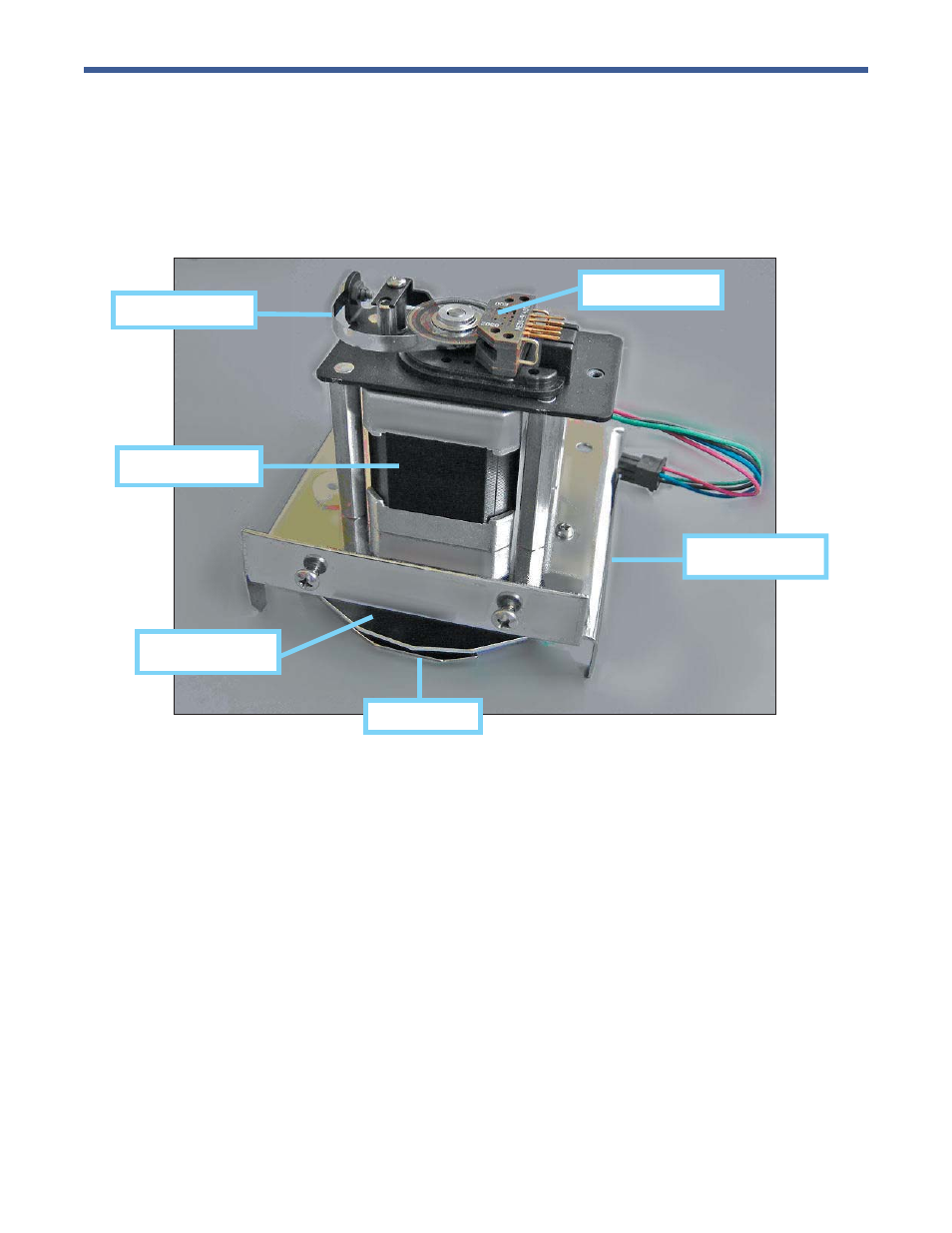

Unlike traditional rotating vane fi eld mills, the CS110 uses a reciprocating shutter. A stepper motor opens and

then closes the reciprocating shutter by 45º during measurements. The reciprocating shutter is electrically con-

nected to ground potential by a fl exible stainless steel strap operated below its fatigue limit, resulting in an ultra-

reliable electrical ground connection. The stainless steel grounding strap and the motor assembly are illustrated

in Figure 4; the 316-L stainless-steel electrodes and base plate are illustrated in Figure 5. An optical position

encoder is used to determine the position of the shutter.

In the reciprocating approach, low-frequency measurement errors associated with electronic drift and changing

insulator leakage currents are inherently compensated for by utilizing the zero electric-fi eld reference available

when the shutter is closed.

Traditional fi eld mills typically consume many watts of power with their continuously operated motors. In the

reciprocating approach, the stepper motor is powered off much of the time, resulting in low power consumption

and low noise. The current required by the reciprocating electric-fi eld meter powered from 12 VDC is illustrated

in Figure 6. As depicted in the fi gure, the average electric-fi eld meter current is a function of the desired measure-

ment rate, which is under user control.

Variable sample rates based on measured results can be implemented to conserve power in solar powered ap-

plications. For example, the CS110 can be programmed to measure electric fi eld at a 10-second rate during fair

weather conditions, and then automatically switch to faster measurements during threatening conditions.

Shutter

Base plate

Sense Electrode

Grounding Strap

Stepper motor

Position encoder

Figure 4.

CS110 Motor Assembly

4