Part 1 installation – Midco RS40 User Manual

Page 6

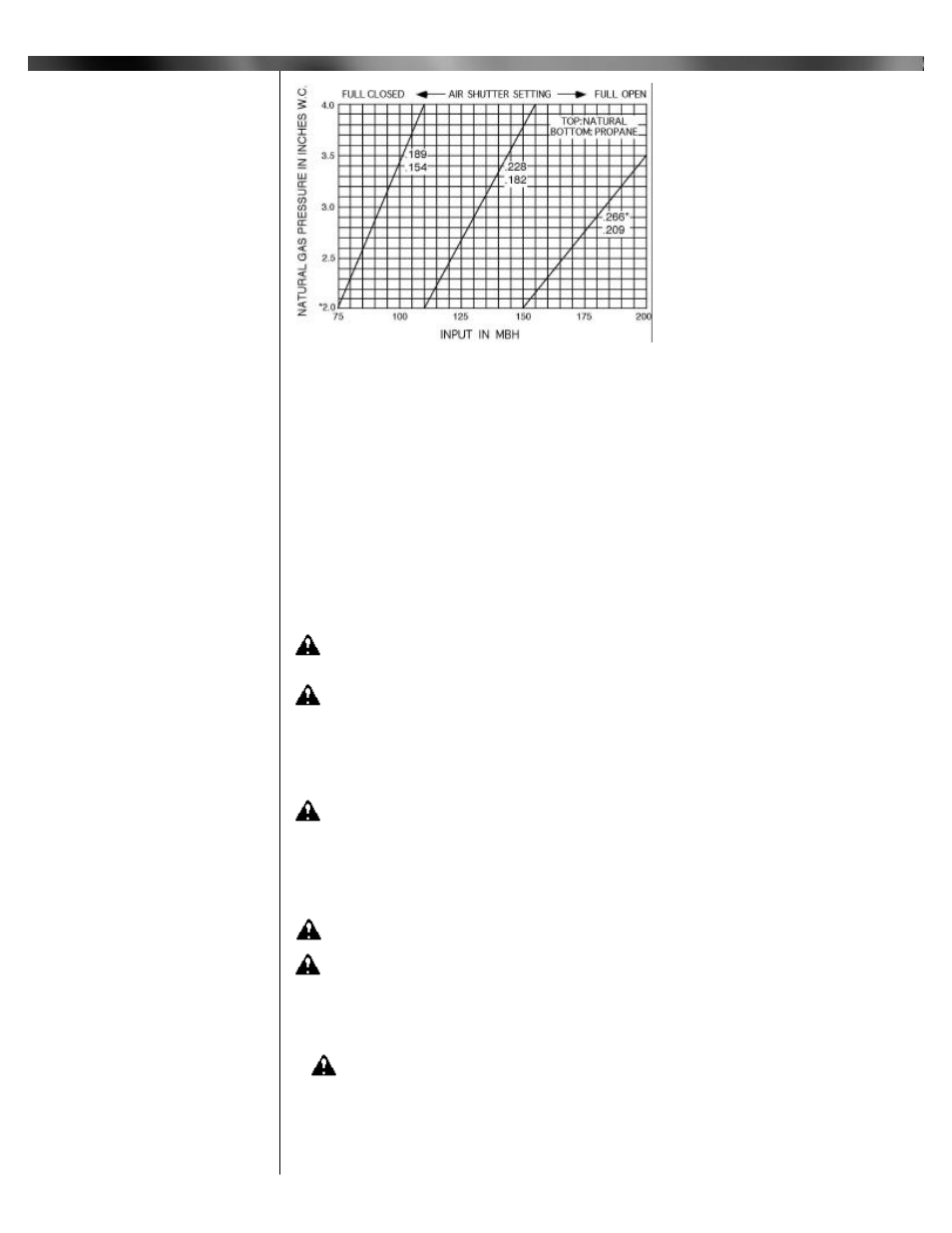

?? As shipped, the installed

NATURAL gas spud has a .266"

diameter orifice size for an input

capacity range of approximately

150 to 200 MBH. Spare spuds

are included in a spare spud

bag (stamped with inch

diameter) for other capacity

ranges and/or conversion to

PROPANE, see Table 3.

?? The Combination Valve

Gas Pressure Regulator is set

to provide 2.0" W.C. manifold

gas pressure for minimum spud

input and the combustion air

shutter is set for maximum spud

input, to provide a lean gas/air

mixture for initial start up.

?? If a standard NATURAL gas

ECONOMITE RS40 is to be

used with PROPANE gas, affix

the PROPANE label from the spare spud bag over the NAT designation on the rating plate

and install the appropriate size main spud as detailed below.

?? If the required firing rate does not fall within the range of the installed spud, or if con-

verting to PROPANE gas, select the correct capacity range from Table 3 and if so indicated,

the spud with the correct orifice size (stamped with inch diameter) from the spare spud bag.

If the required firing rate is at the minimum of a capacity range, select the next lower range

spud.

?? To change the main spud, turn off the Main Manual Shut-Off Valve and burner power,

remove the backplate, disconnect the field installed union located between Combination

Valve and Main Manual Shut-Off Valve and remove manifold assembly. Remove Nozzle

Assembly from Main Gas Spud, see Figure 7.Unscrew the installed main spud from the

manifold pipe and install the selected main spud. Reassemble burner in reverse order.

WARNING: Reposition the combustion air shutter for the maximum firing rate of

the selected spud capacity range. Do not change the Combination Valve Main Gas

Pressure Regulator setting at this time.

CAUTION: The approximate air and gas settings described above are for initial

start-up only. Final settings must be made in accordance with Section VIII, Initial

StartUp/Adjustment Instructions for adjustment of the manifold gas pressure are

detailed in Section XI, Combination Gas Valve.

_____________________________________

WARNING: Ignition is automatic. Make spark observations into combustion

chamber only with Main Manual Shut-Off Valve closed. Confirm that gas utilization

equipment does not contain any accumulated gases. Purge as described in Step 3

below.

1.

Check the burner piping and valves for gas leaks by applying a weak liquid soap

solution to unions and joints with the gas supply on. Leakage will be indicated by the

appearance of soap bubbles. Locate and correct all gas leaks before proceeding.

WARNING: DO NOT USE OPEN FLAME FOR CHECKING.

2.

Purging the air from the gas supply line at this step will expedite the first light-off.

CAUTION: Purge gas to outside the building. Do not purge into the gas

utilization equipment.

3.

To purge the gas utilization equipment and chimney of any accumulated gases, turn

Manual Gas Cock Knob on the Combination Valve to OFF, turn burner power on and set

the operating control to ON or thermostat to call for heat. Let the blower run long enough to

accomplish four air changes, but not less than five minutes.

4.

CAUTION: Make sure that the capacity range of the installed spud and the

preliminary combustion air shutter setting are suitable for capacity rating of the gas

utilization equipment. Refer to Section VII, Main Gas Spud and Table 3.

5.

RESET the Electronic Control by setting the operating control to OFF or the thermostat

below room temperature for at least 30 seconds, see Section XII, Electronic Control.

6.

Confirm that Main Manual Shut-Off Valve is open. Turn Manual Gas Cock Knob on

Combination Valve to ON.

VIII Initial

StartUp/Adjustment

6

VII Main Gas Spud

Continued

*Main Gas Spud Orifice Size, approximate Manifold Pressure

setting as shipped. Data shown is approximate and based

on "0" overfire pressure at sea level

Table 3: Main Gas Spud Capacity and

Preliminary Gas and Air Settings

Part 1

Installation Continued

Part 1 Installation