Part 2 service, Ix nozzle and pilot – Midco E20BP User Manual

Page 6

and yellow tips for NATURAL gas or with well defined

yellow tips for PROPANE gas.

11.

Check the operation of the burner; start and stop it

several times with the thermostat or operating control.

12.

With the burner running, check the operation of all limit

and associated controls.

13.

PERFORM THE FOLLOWING FINAL ADJUSTMENTS

for combustion and flue gas temperature. Take the flue

gas samples and temperature immediately ahead of the

draft control.

A.

Check the draft control to make sure there is no spillage

of flue products into the room.

B.

Make the final setting of the air shutter by

checking the flue gases with an ORSAT or similar

combustion testing instrument. The carbon monoxide

content should conform to local codes, or, in their

absence to the level specified in the United States or

Canadian Standard reference on the front cover of

this manual; and the carbon dioxide content should

be approximately 9.5% for NATURAL and 12.1% for

PROPANE, or within the limits prescribed by the local

codes.

C.

The flue gas temperature should be above 325¡F but

not exceeding 550¡F. Excessive flue gas temperatures

will result in low efficiencies. Low flue gas temperature

may cause excessive condensation.

14.

FILL OUT THE INSTALLATION ADJUSTMENT DATA

TAG and affix to the burner or converted appliance

.

NOTE: For subsequent normal starting and shut off

procedure, refer to CONSUMER INSTRUCTIONS or

to the instruction plate mounted on the burner.

3600 x Test Dial Size x BTU Value

No. of Seconds for One Rev. Test Dial

Then divide by 1,000 for MBH value.

Example: 3600 x 1 x 1000

20

= 180,000 BTU/Hr. = 18

= BTU/Hr.

7.

With pilot lit, wait one minute; then release Manual Gas

Cock Knob on Combination Valve and turn to ON. If pilot

goes out when knob is released, turn to OFF then PILOT

and repeat purging and pilot lighting instructions detailed

above. Incorrect pilot flame gas pressure may prevent

proper heating of thermocouple causing the pilotstat

safety control to drop out. Refer to Section IX for pilot

adjustment.

8.

Turn operating control to ON or set thermostat above

room temperature. Main flame should come on when the

motor reaches operating speed. If not, refer to Trouble

Chart. To make a preliminary setting of the burner input,

determine the manifold gas pressure required from Table

3 and adjust the combination valve pressure regulator

accordingly. See Section XI.

9.

To determine the firing rate for NATURAL gas:

Accurately time test dial for the number of seconds for

one revolution and use the following formula. All other

gas utilization equipment must be off.

For PROPANE gas, consult your local supplier for method

to determine firing rate.

10.

Readjust the air shutter to provide a quiet, soft flame

-- blue at the burner nozzle with well defined orange

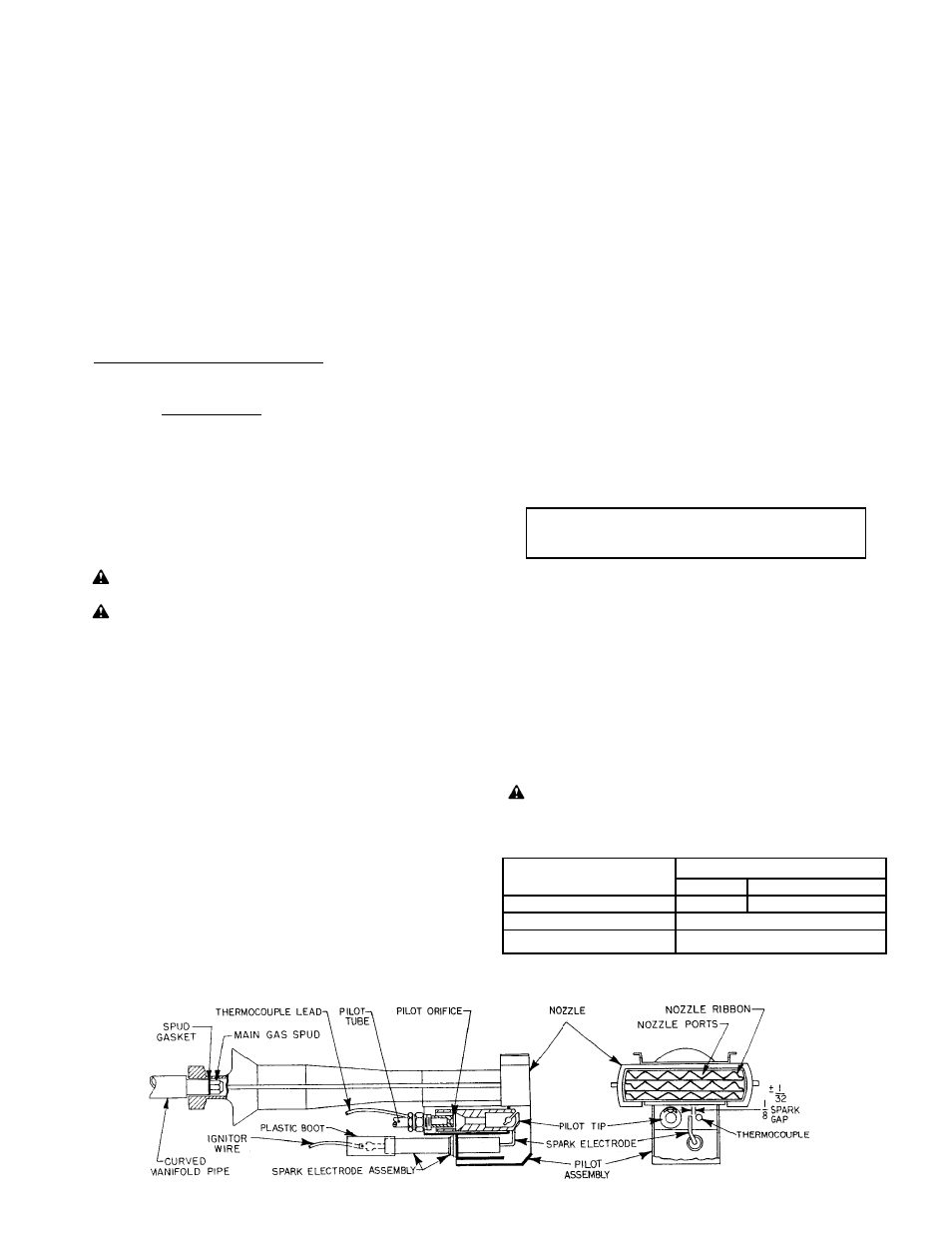

FIGURE 6

Nozzle and Pilot Assembly

-6-

IX

NOZZLE AND PILOT

The nozzle and pilot assembly can be removed as a unit by

removing the back plate, disconnecting the factory installed

union located between combination valve and manifold slide

plate, and pulling out curved manifold pipe. Disconnect

thermocouple and pilot tube at Combination Gas Valve.

Withdraw nozzle assembly, enough to permit disconnecting

ignitor wire before removing nozzle and pilot assembly

completely.

■

When the pilot flame gas pressure is in the proper range,

lint, dust or corrosion is the usual cause for most service

problems. When servicing, clean the nozzle ribbon and pilot

assembly including the pilot orifice and electrode porcelain.

■

If cleaning does not eliminate a pilot outage problem, further

checks are required.

■

Check to verify that the burner nozzle is not installed in too

far. See Figures 1 and 2.

■

A continuous draft is required for the proper operation of the

pilot. This is no problem in the usual up-draft heating

appliance. However, in down-draft or horizontal appliances,

especially during periods of infrequent operation, the available

draft may become nil and result in the pilot products of

combustion being recirculated and snuffing out the pilot.

Excessive draft (over -.05" W.C.) or reverse draft may also

result in nuisance pilot outages. Where a suitable continuous

draft cannot be provided, a spark ignited burner should be

considered.

■

Check that the pilot orifice size is correct (refer to Table 4).

CAUTION:

Do not indiscriminately increase pilot orifice

size. Pilot troubles are rarely cured in this manner and

new troubles may be introduced by causing the pilot flame

to float and lose contact with the thermocouple.

Nominal BTU/Hr. Value

NAT-1000

PROPANE-2500

Orifice Diameter

.018

.012

Pilot Flame Gas Pressure

3.5 - 7.0" W.C.

Approx. Capacity

800 BTU/Hr.

TABLE 4

Pilot Specifications

PART 2

SERVICE

DANGER: Be sure the Main Manual Shut-Off Valve, Combination Valve and Burner Power Switch are

turned off before removing any parts for service.

WARNING: Do not attempt to FIRE the burner with the burner backplate removed as air from the blower

will not reach the combustion chamber and a dangerous level of unburned gas could accumulate.