Part 1 installation, Specifications, Icombustion chamber ii electrical – Midco Economite RE4400DS HTD User Manual

Page 2

Part 1 Installation

Specifications

The ECONOMITE Model RE 4400DS HTD (High Turn Down) burners with direct spark

ignition are adaptable to most gas utilization equipment.

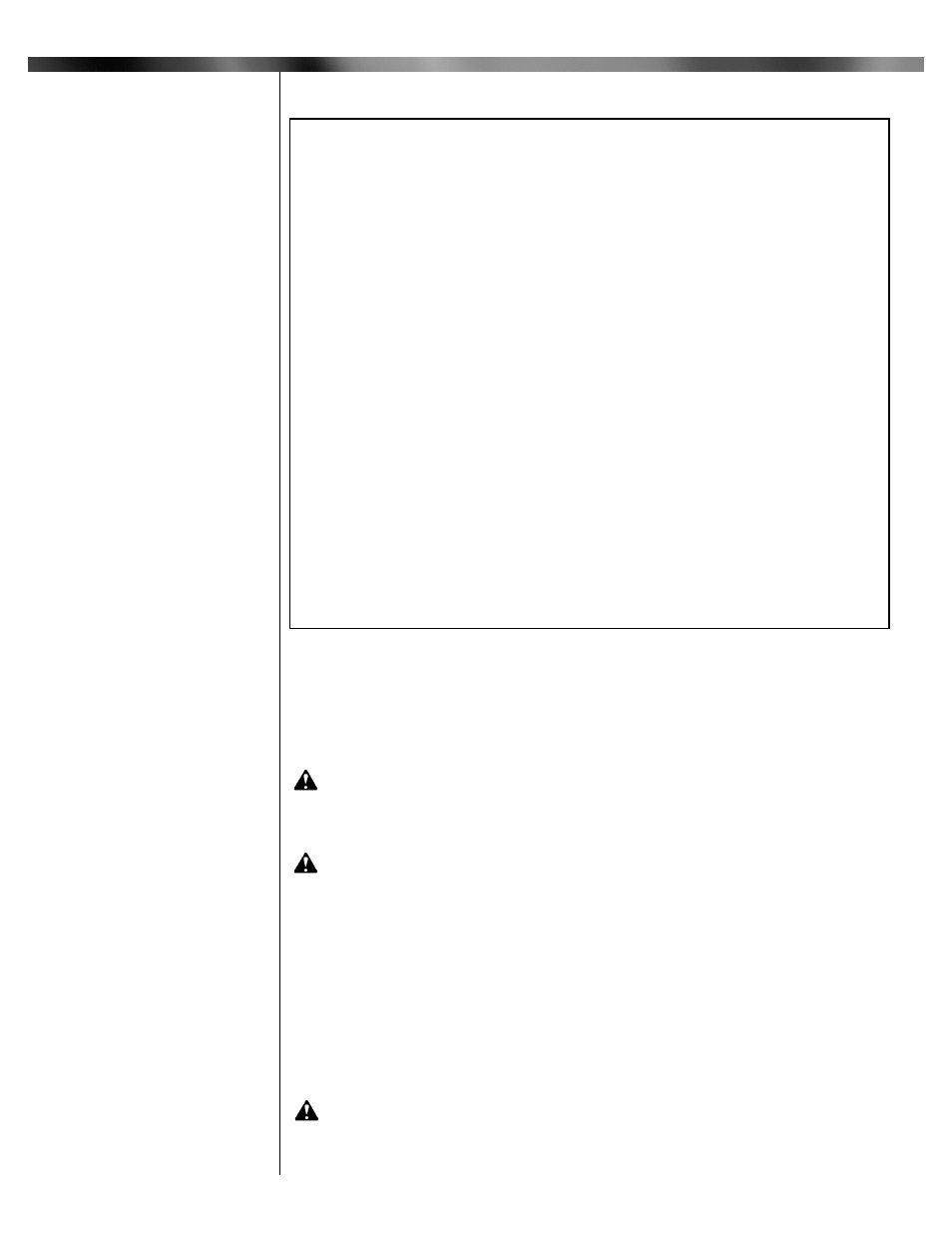

AIR DELIVERY (Approximate Air Delivery at Zero Draft)

RE4400DS HTD ..... 87 SCFM

1

FIRING RATE (NATURAL )

2

(Based on 0 draft over fire pressure)

MAXIMUM MBH

3

400

MINIMUM MBH

3

20

GAS SUPPLY PRESSURE REQUIRED

Min

Max

250 MBH ................................................... 7.0" to 14.0" W.C

350 MBH ................................................... 7.0" to 14.0" W.C

400 MBH ................................................... 7.0" to 14.0" W.C

TUBE DIAMETER ........................................................... 4"

RECOMMENDED COMBUSTION CHAMBER SIZE (AT MAX. BTU/HR)

WIDTH

10"

LENGTH

16.5"

ELECTRICAL SUPPLY

4

.....................................120/208/230 VAC...........60 Hertz

ELECTRONIC CONTROL VOLTAGE ................ 24 VAC

FLAME SAFETY....Direct Spark Ignition of Main Flame, Electronic Safety

TABLE 1: Burner Specifications

1.

SCFM = Standard Cubic Feet / Minute.

2.

All Ratings Based on 1000 BTU/Cu. Ft. NATURAL Derate burner for altitude over 2,000 feet by

4% for each 1,000 feet above sea level.

3.

1 MBH = 1,000 BTU/hr.

4.

Burners available in 115V, 208V or 230V power supply. Consult burner name plate for correct

power supply, or as recommended by the equipment manufacturer.

____________________________

The burner tube, or the stainless steel sleeve that is included with the burner, must be

sealed air tight into the combustion chamber opening with refractory material. The sleeve is

preferred as it is designed to properly locate the end of the tube relative to the inside wall of

the combustion chamber, and to permit burner removal

or as recommended by the equipment

manufacturer

.

CAUTION: In no case should the burner tube be allowed to extend into the

chamber because high combustion chamber temperatures will cause premature

electrode, burner tube and sleeve deterioration.

____________________________

CAUTION: Refer to wiring diagram in Figure 1 or located on the burner

housing.

Installation wiring and grounding to the burner must conform to local codes, or, in their

absence in the United States to National Electric Code, ANSI/NFPA No. 70 latest edition;

in Canada, to Canadian Electrical Code Part 1, CSA Standard C22.1

Use copper wire not less than 14 gage for line voltage wiring. Hook up to a dedicated line

with an on-off disconnect switch and a minimum 10 Amp breaker, or as required by

equipment manufacturer.

The frame of the burner should be well grounded. A ground lug is located in control box

for positive grounding where insulated pipe couplings are used or where any doubt exists

regarding grounding sufficiency.

Confirm that the polarity is correct—hot wire to strip terminal L1, neutral L2—and that the

neutral line is not subject to induced low voltage (check L2 to earth ground) from other

equipment, as that can cause the Electronic Control to malfunction.

Each installation must include suitable limit control(s).

CAUTION: Label all wires prior to disconnection when servicing controls.

Wiring errors can cause improper and dangerous operation. Verify proper operation

after servicing.

Part 1

Installation

2

I

Combustion

Chamber

II

Electrical