3 installing the camera, 4 cooling circuit, 3 installing the camera 6.1.4 cooling circuit – Videotec NXW User Manual

Page 8

EN - English - I

nstruc

tions manual

6

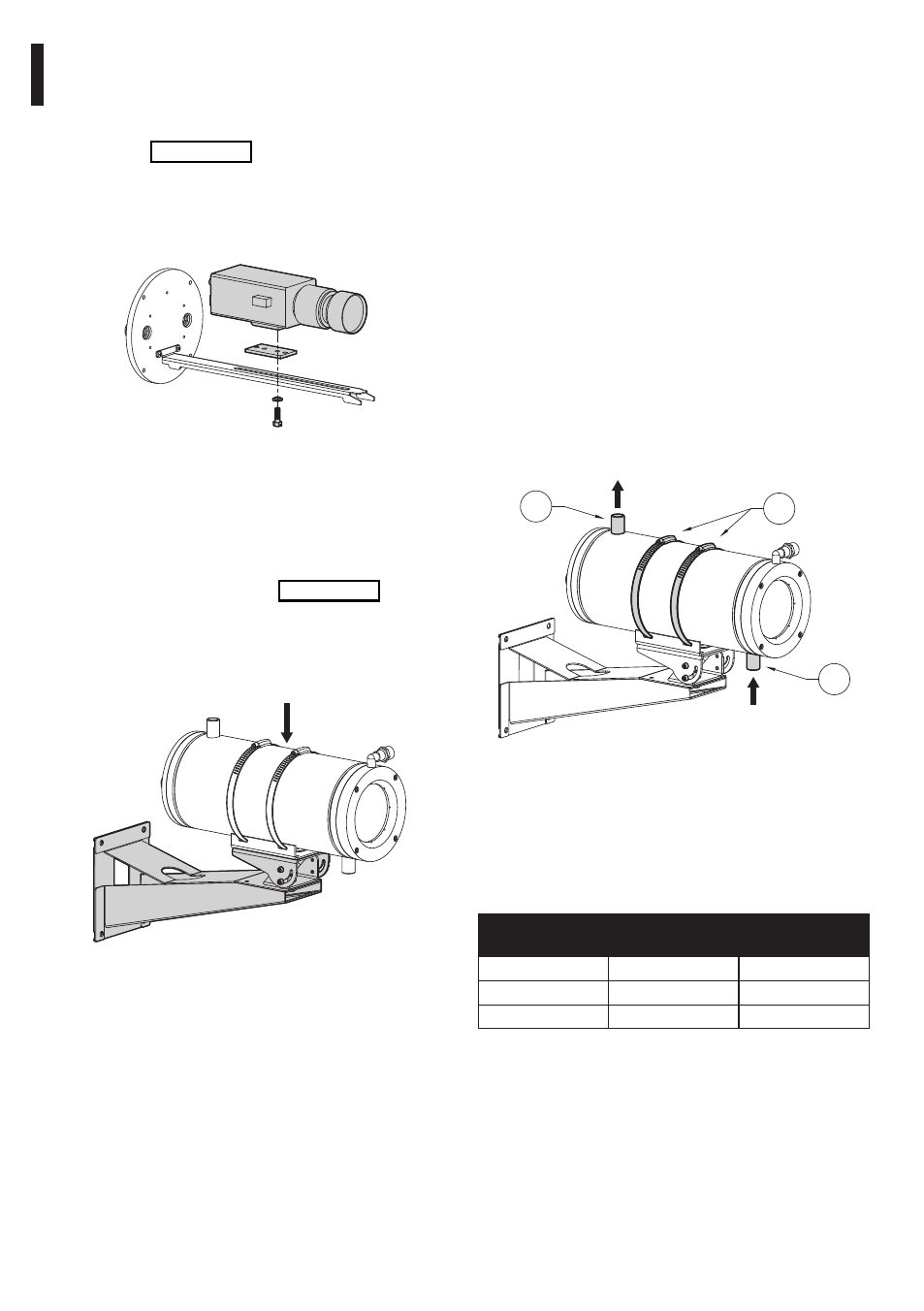

6.1.4 Cooling circuit

This section describes how to connect the

housing to the water cooling circuit and gives

the results of experimental data to determine

the dimensions of the latter. The housing is

equipped with 1/2”Gas, threaded, cooling

water inlet and outlet connectors with.

Use the connector on the housing body near the

front (01) as the cooling water inlet and the connector

near the back (02) as the cooling water outlet.

This is only a general indication since the direction

from which the heat source originates and

installation constraints may make it necessary to

adapt the position of the water connectors and

the choice of input and output according to the

specific installation. This is possible because the

housing body can be rotated with respect to the

support base by adjusting the locking ties (03).

01

02

03

OUT water 1/2“Gas

IN water 1/2”Gas

Fig. 07

The following experimental data give the water

flow rate required to maintain a temperature

below 45°C inside the housing with an external

temperature Tmax =400 °C and refer to the

use of water as cooling liquid with an input

temperature to the housing of 20°C.

T

environment

[°C]

WATER FLOW

RATE [L/MIN]

T

inside

housing

[°C]

200

2

32

300

2.2

41

400

6.5

44

Tab. 01

6.1.3 Installing the camera

This section describes how to install

the camera inside the housing.

Open the housing following the instructions

given above (Fig. 04, page 5).

Attach the camera to the internal slide with the 1/4”W

screw using the insulating bush. If necessary use the

spacers supplied and the appropriate 1/4”W screws

so as to position the camera and lens correctly.

Fig. 05

Make the correct electrical connections for

the camera and lens, passing the cables

through the cable glands. Make sure the

latter are firmly locked in place.

Close the housing by proceeding in the reverse

order to that described above (Fig. 04, page 5). Make

sure the sealing ring on the rear flange is correctly

inserted in its seating so as not to damage it.

Attach the housing to the bracket if this

has not been assembled already.

Fig. 06