Maintenance, Kdar company 11, Maintenance schedule—pump – Hot Max Torches PW2000 User Manual

Page 12: Connections nozzles, Warning, Water screen, Preparing for transportation, Preparation for storage—pump

KDAR Company

11

Maintenance

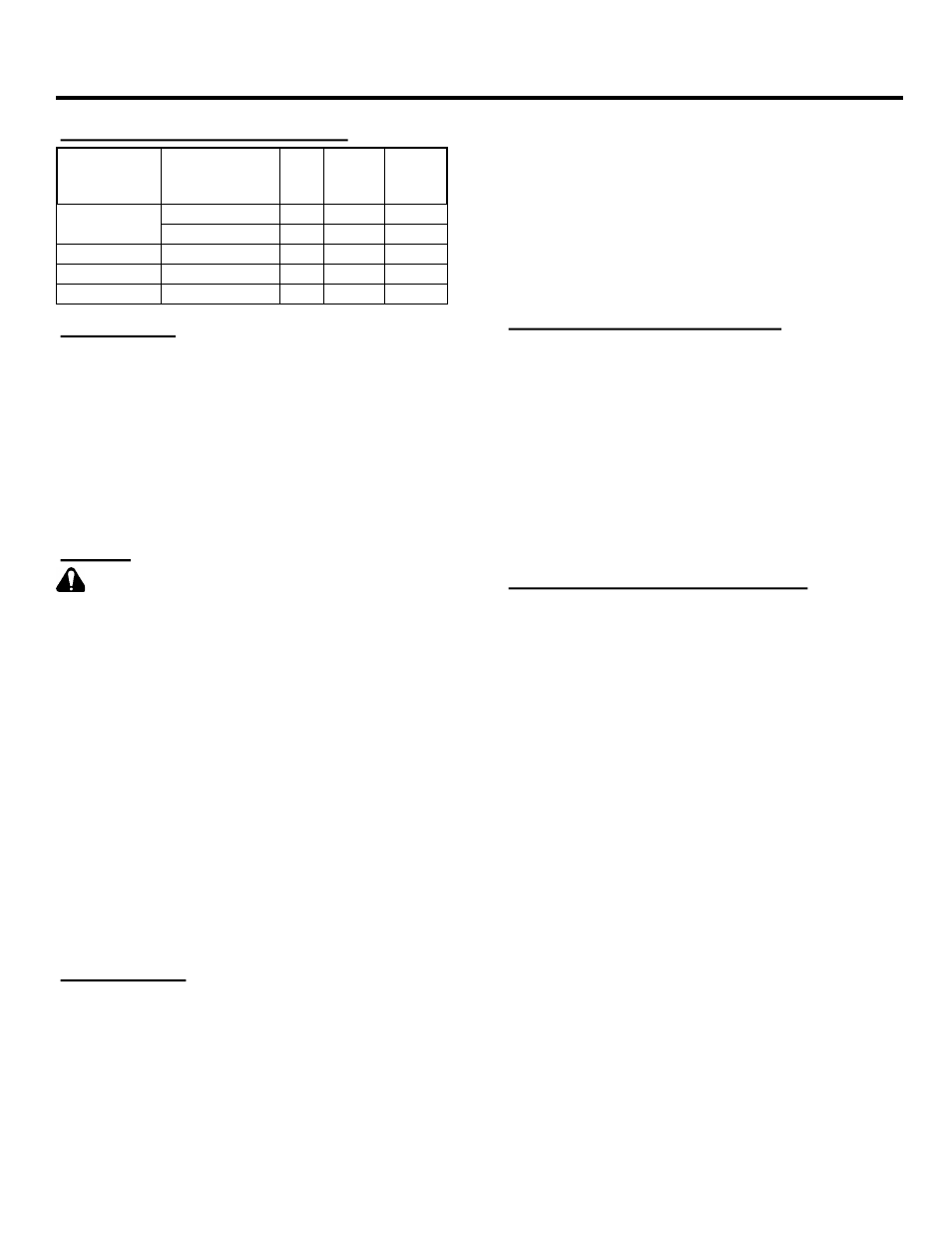

Maintenance Schedule—Pump

1. Check all connections on the pump, hose, gun

and wand before each use.

2. Clean connections if required.

3. Every 10 hours or sooner if needed, lubricate

connections on the pressure washer hose, gun

and wand with a Teflon® based, waterproof

lubricant/sealant to prevent leaks and damage

to o-rings.

Item

What to Do

Each

Use

Every

10

Hours

Every

500

Hours

Connections

Check

X

Lubricate

X

Nozzle

Check for Clogs

X

Water Screen Check for Clogs

X

Seals

Replace

X

Connections

Nozzles

1. Check nozzle before each use.

Note: A clogged nozzle will cause the pres-

sure in the pump to be too high and can

cause the pump to over heat.

2. Clean clogged nozzles with the tip cleaner pro-

vided with your power washer or a firm piece

of wire.

3. Flush water backwards through the nozzle.

4. Re-inspect and connect to the wand if clean.

5. If nozzle is unable to be cleared, replace with a

new nozzle.

WARNING

Never clean the nozzle while the nozzle is con-

nected to the pressure washer gun. Serious inju-

ry may occur as a result of accidental discharge

of high pressure water.

Water Screen

This power washer is equipped with a water inlet

screen to protect the pump. This screen is located

inside the water supply connection.

1. Carefully, remove the screen.

2. Thoroughly wash the screen.

3. Carefully replace the screen.

Take care not to damage the screen in any way;

the pump may be damaged if foreign matter

gets into the pump. If the screen is damaged,

DOT USE THE POWER WASHER WITH A

DAMAGED SCREEN OR NO SCREEN. Or-

der a new screen and replace before using.

Preparing for Transportation

1. Turn the engine switch and fuel valve to the

off or stop position.

2. Let the engine cool before transporting.

3. Keep the power washer level to prevent fuel

spillage.

4. Take care not to drop or strike the power wash-

er when transporting.

5. Do not place heavy objects on the power wash-

er.

Preparation for Storage—Pump

If the power washer is going to be stored where the

temperature will get below 32° F, the risk of dam-

age from freezing will be reduced using the fol-

lowing procedure.

1. Turn off the water supply, disconnect the gar-

den hose and depress the trigger on the gun to

relieve pressure. Leave the high pressure hose

connected.

2. Carefully, tip the unit on its side with the water

supply connector up.

3. Pour in about 1/4 cup of antifreeze.

4. Disconnect the spark plug wire.

5. Pull the recoil several times to distribute the

anti freeze within the pump.

6. Re-connect the spark plug wire.

An alternate method for reducing the risk of dam-

age from freezing is as follows.

1. Stop the pressure washer.

2. Detach the garden hose.