Maintenance – Hot Max Torches PW2000 User Manual

Page 11

KDAR Company

10

Fuel Valve Cleaning

1. Remove the sediment cup and O-ring at the

bottom of the fuel valve with a small wrench.

2. Clean and wash out the sediment cap with a

nonflammable or high flashpoint solvent.

3. Replace the sediment cap and O-ring.

Sediment

Cup

Fuel Strainer Cleaning

1. Remove the plastic fuel strainer from under the

fuel tank cap.

2. Clean and wash out the strainer with a non-

flammable or high flashpoint solvent.

3. Replace strainer.

Spark Plug Service

Recommended Spark Plug:

BP6ES (NGK)

W20EPR-U (Nippondensu)

To insure proper engine operation, the spark plug

must be properly gapped and free of deposits.

WARNING

If the engine has been running the muf-

fler will be very hot. Care must be taken

not to touch the muffler when removing

the spark plug.

1. Remove the spark plug cap.

2. Clean any dirt from around the spark plug

base.

3. Use the wrench supplied with the generator to

remove the spark plug.

4. Visually inspect the spark plug and discard if

the insulator is cracked or chipped.

3. Clean with a wire brush if the spark plug is to

be reused.

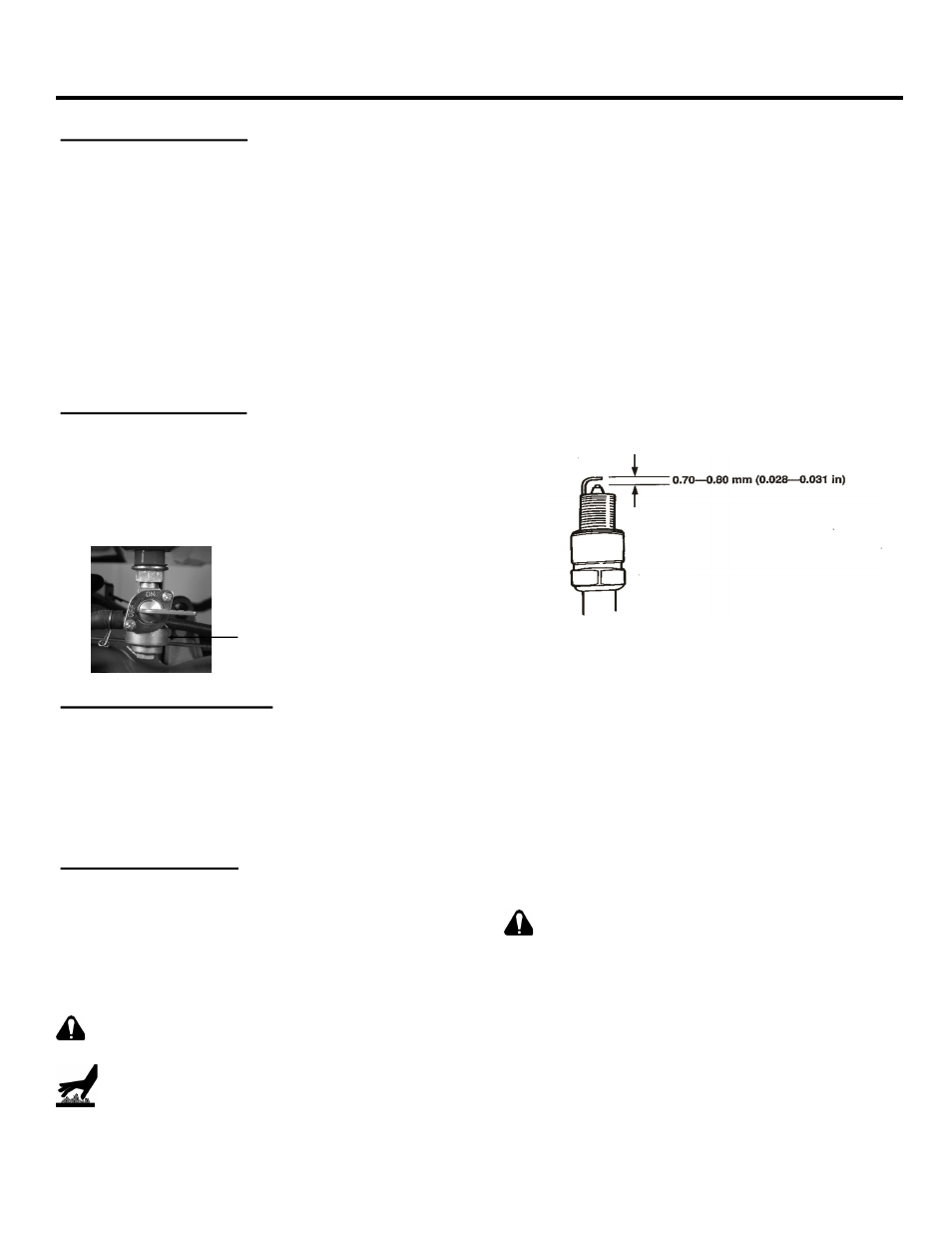

4. Measure the plug gap with a feeler gauge.

5. Correct as necessary by carefully bending the

side electrode.

The gap should be: 0.70—0.80 (0.028-0.031

in.)

8. Check to make sure the spark plug washer is in

good condition.

9. Thread the spark plug in by hand to prevent

cross-threading.

10. After the spark plug is seated, tighten with the

spark plug wrench to compress the washer.

If installing a new spark plug, tighten 1/2 turn

after the spark plug seats to compress the

washer. If reinstalling a used spark plug, tight-

en 1/8-1/4 turn after the spark plug seats to

compress the washer.

CAUTION

The spark plug must be securely tightened. An

improperly tightened spark plug can become

very hot and could damage the engine.

Never use spark plugs which have an improper

heat range. Use only the recommended spark

plugs or equivalent.

Fuel Filter Cleaning

1. Drain fuel from tank.

2. Disconnect fuel line from fuel valve.

3. Remove fuel valve from tank.

4. Remove Fuel filter from the top of the fuel

valve by unthreading (should be able to be re-

moved with fingers.

5. Clean fuel filter with a nonflammable or high

flashpoint solvent.

6. Reattach fuel filter to fuel valve and reattach

fuel valve to tank and fuel line.

Maintenance