Hot Max Torches MM-1 User Manual

Page 9

KDAR Company

8

Operation

8. Check all connections for leaks. Leaks can not

be seen, therefore, use soapy water on all con-

nection points to insure there are no leaks.

9. Open the oxygen control knob on the torch han-

dle two full turns. No oxygen should flow at this

time because the oxygen flow is controlled by

the valve on the cutting head.

10. Insure oxygen flows by turning the control knob

on the cutting head a quarter of turn. Quickly

close the valve after confirming oxygen flow.

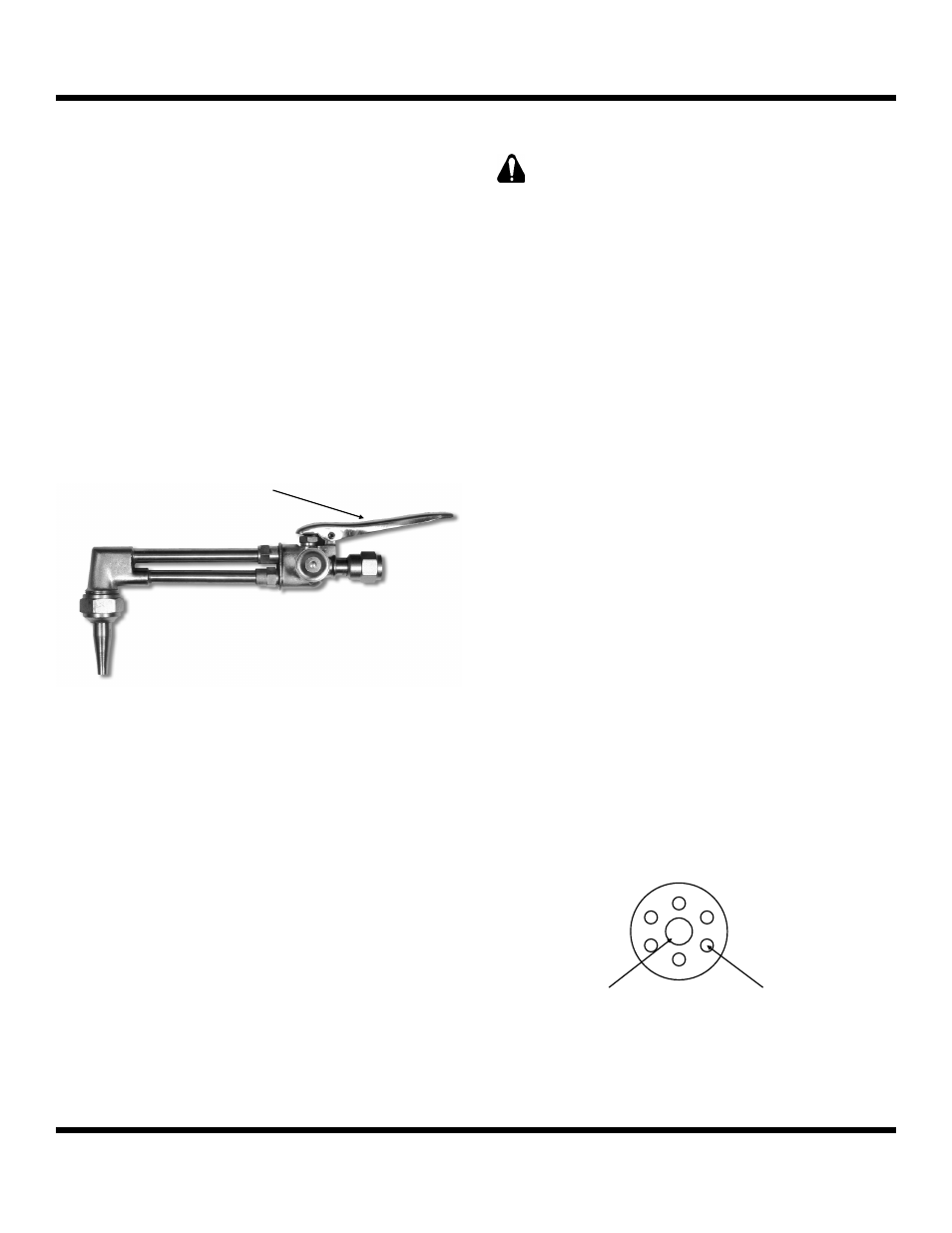

11. Press the oxygen cutting lever (1) briefly to con-

firm a steam of oxygen flows from the center

hole in the cutting tip.

12. Slowly open the acetylene tank valve with the

tank key. This valve turns left (counter clock-

wise) to open. Open slowly and not more then 1

turn.

13. Open the acetylene regulator until the regulator

reaches the desired working pressure.

Note: Working pressure charts ar e found on

page 9.

14. Briefly open the acetylene control knob on the

torch handle to confirm acetylene is flowing.

15. Check all connections for leaks using soapy wa-

ter..

1

Lighting the Torch

Prior to lighting the torch make sure the

hoses are behind the operator and that

there is no chance of them being hit by a

hot spark or slag.

At this point the operator should be wear-

ing appropriate protective clothing such as

gloves and goggles.

1. Open the acetylene control knob on the torch

handle just enough to let some gas flow about a

quarter turn.

2. Holding the striker close to the cutting tip

squeeze it a few times to create the sparks re-

quired to light the acetylene.

Note: A oxyacetylene torch should NEVER be lit

with oxygen present in the mixture.

Adjusting the Flame

1. Open the oxygen valve on the cutting head.

2. Develop a neutral flame at the preheat holes

(Figure 4) by that results in a cone about 1/8th

inch long. This is accomplished by alternately

increasing the flow of acetylene and then oxy-

gen.

Figure 4

Preheat Holes

Cutting Hole

WARNING