Hot Max Torches MM-1 User Manual

Page 8

KDAR Company

7

Operation

Shutting Down

1. Using the acetylene control knob turn off the

flow of acetylene to the welding tip. This will

allow oxygen to continue to flow and will insure

any debris that may be in the orifice is blow out.

2. Turn off the oxygen using the oxygen control

knob on the torch handle.

3. If shutting down for only a short period of time,

close the tank valve on both the acetylene and

oxygen and leave the hoses filled with gas.

4. If shutting down for a longer per of time, close

the tank valve on both the acetylene and oxygen.

5. Bleed the acetylene line by opening the acety-

lene control knob on the torch handle. Watch the

regulator gauge, it should move to reading zero.

6. Close the acetylene control knob on the torch

handle.

7. Bleed the oxygen line by opening the oxygen

control knob on the torch handle. Watch the reg-

ulator gauge, it should move to reading zero.

8. Finally release the pressure on the regulator dia-

phragm by opening the regulator valve until little

or no pressure is felt. This will significantly im-

prove the life of the regulator.

Setting Working Pressures—Cutting

While setting working pressure gases will

be released from the torch. It is important

that no open flame or other heat source is

present during this operation.

Note: At this point the tanks should be turned off

and both the acetylene and oxygen lines cleared of

gas.

WARNING

1. Remove the welding tip from the torch handle

and attach the cutting head. Tighten with a

wrench.

2. Insure that the both the acetylene and oxygen

control knobs on the torch handle are closed

(clockwise).

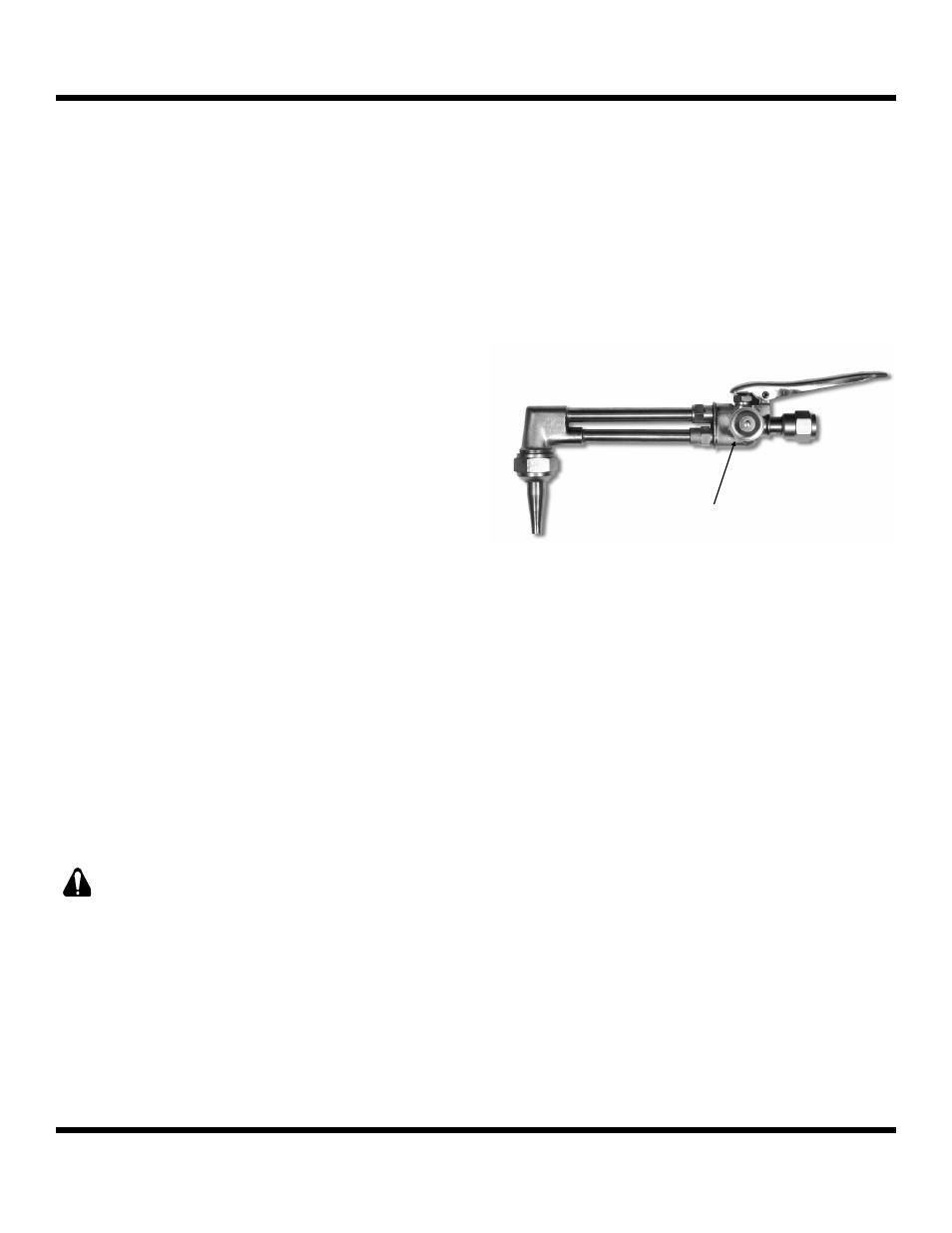

3. Insure the oxygen control knob (1) on the cutting

head is closed (clockwise).

4. Select the appropriate cutting tip for the material

being cut and attach it to the cutting head (the

Mobile Max is shipped with a #1 tip assembled

to the cutting head). Tighten with a wrench.

Note: The char t on page can be used as a

guide for selecting the correct tip for the job.

5. Close (counter clockwise) both the acetylene and

oxygen regulator valves.

6. Slowly open (counter clockwise) the oxygen cyl-

inder valve to allow oxygen to flow to the regu-

lator. Once the regulator begins to register pres-

sure, open the valve an additional 1 to 1 1/2

turns.

Note: This must be done slowly, as a surge of

pressure could damage the regulator diaphragm.

7. Open the oxygen regulator until the regulator

reaches the desired working pressure.

Note: Working pressure charts ar e found on

page 9.

1