Dake Model G-75 User Manual

Page 9

5/20/2010

Model G-75

9

4. Cleaning and Maintenance:

1. After every use clean the machine thoroughly. If using compressed air take extra care.

Keep contact wheel and vent grooves clean, upper grinding surface clean especially the

graphite strip under the belt. Sweep floor around machine to prevent build up of grinding

dust.

2. Routine Maintenance consist of frequent cleaning, replacement of contact wheel when

needed, keeping all fasteners tight, emptying the spark catch box often. Replace any

worn parts without delay. Keep Plexiglas eye guard clean, and replace when necessary.

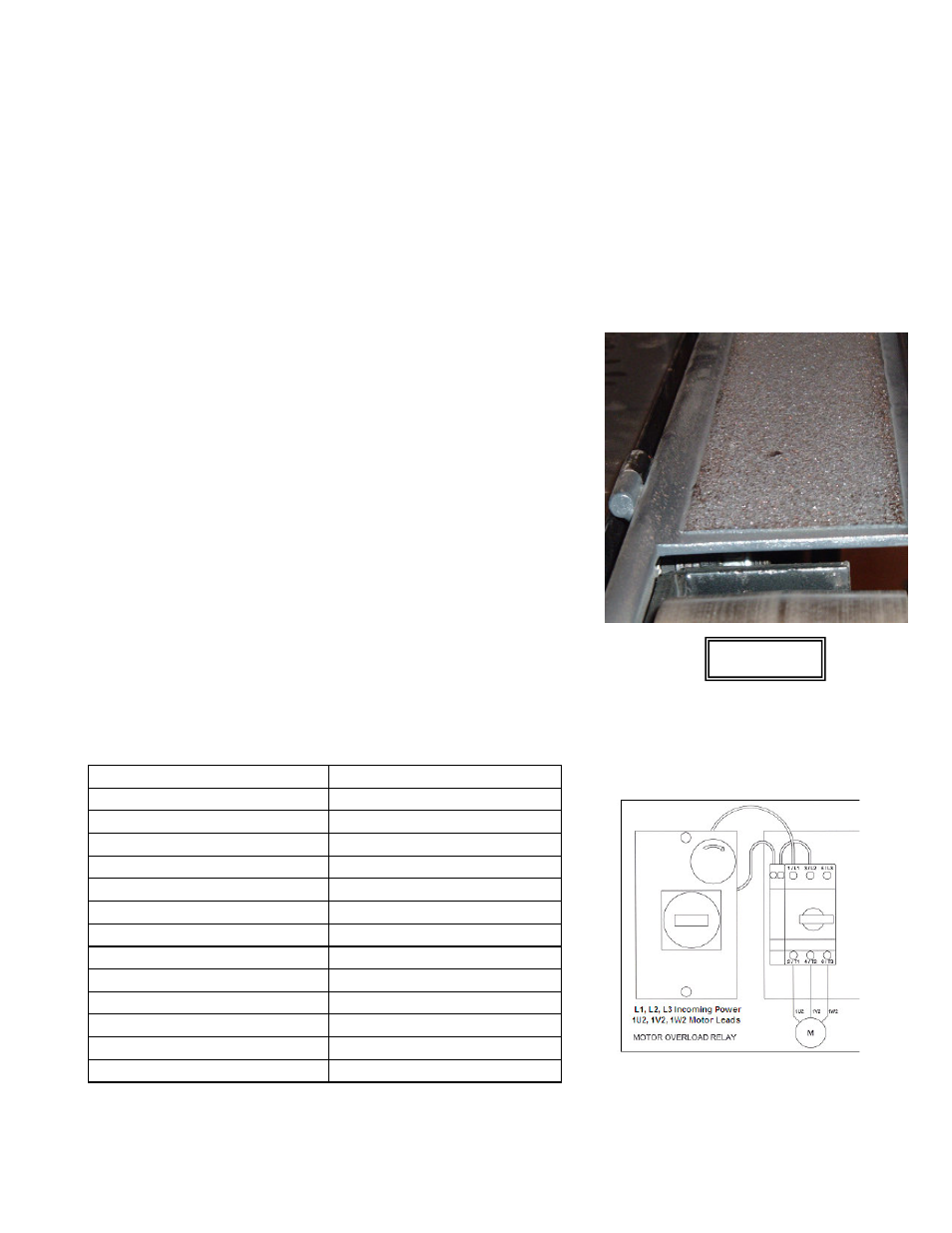

3. After time the graphite wear strip may need to be

changed. (Figure 15) This is done by

removing the old strip with a putty knife and cleaning

the surface. Using contact cement the new strip can

be glued into place. NOTE: Never use the machine

if the graphite wear strip is damaged or missing!

4. TIP: Exhaust from the grinder will throw sparks a

good distance and should be controlled. One way of

keeping the area safe and clean is to install a metal

elbow (such as used on dryer vents) to the exhaust

flange on the back of the grinder head. This elbow is

then directed downward into a bucket of water. This

keeps sparks from flying outward, cools the material

slag and keeps dust to a minimum.

5. Machine specifications:

Machine type

Horizontal belt grinder

Belt size

3” x 79”

Horse Power

4 HP

Contact wheel size

3” x 8”

Belt speed

6600 f.p.m.

Grinding plane

3” x 21”

Electrical components

CE approved

Weight

187 lbs.

Work height

18 - 48 in.

Base dimensions

17 x 21 in.

Machine width

22 in.

Machine length

39 in.

Over all height

43 in.

Noise levels

85 dB @ no load

Figure 15