Sar 440 sa gds, Regulating the machine – Dake Model SAR 440 User Manual

Page 11

11

SAR 440 SA GDS

A

B

C

REGULATING

THE MACHINE

7.1 - Blade tension assembly

CUTTING DIRECTION

7

The ideal blade tension is obtained by rotating the hand wheel belt

tensioner until the blade tension pressure reaches 160 Bars

otherwise the saw will not operate.

N.B.: when the saw is not in use it is recommend to loosen the

blade tension.

It is always recommend to use the blade sizes suggested in

this manual.

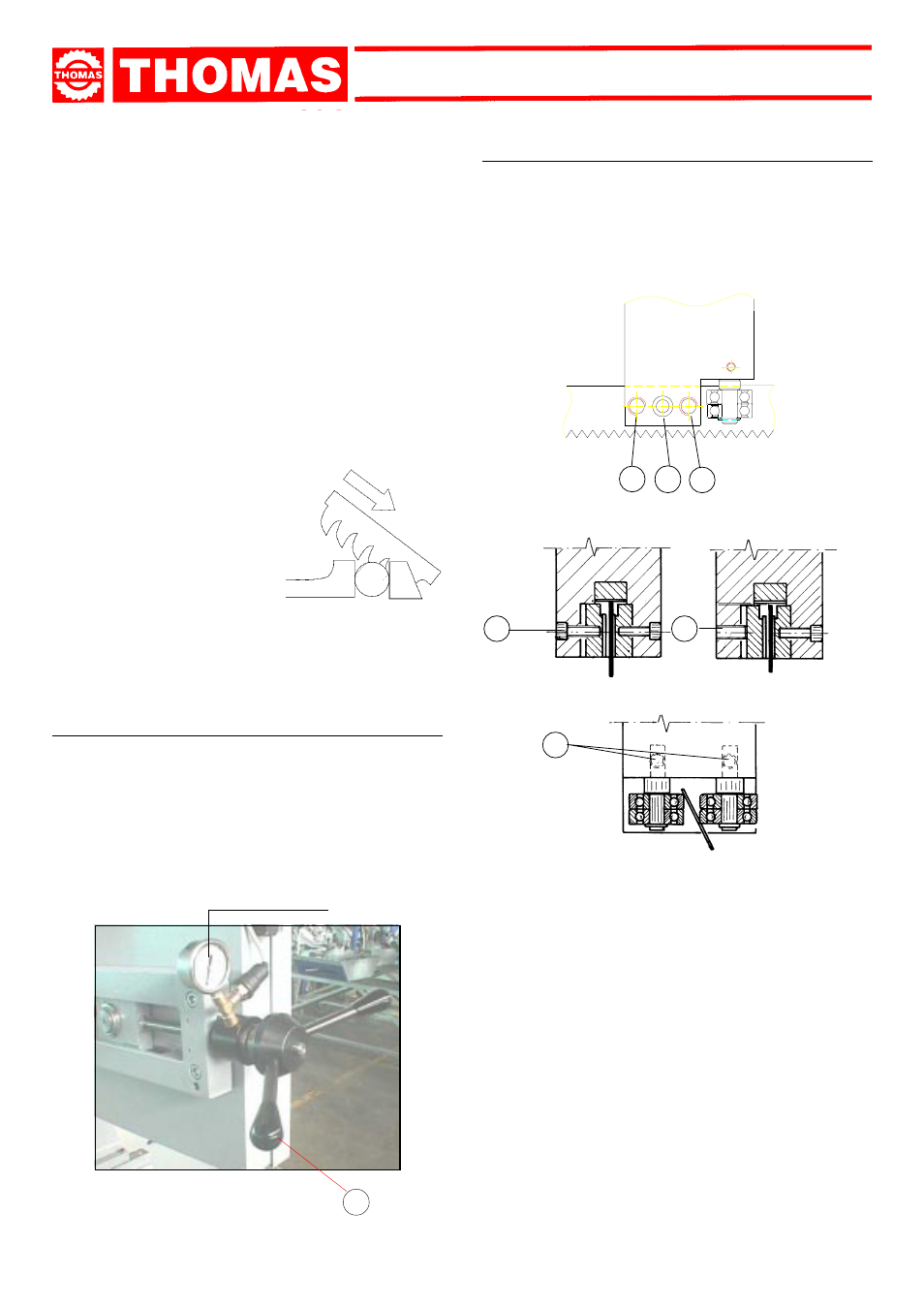

7.2 - Blade-guide head

Blade guiding is obtained by means of plates which are regulated

during the testing phase according to blade thickness.

When replacing a blade, ensure that the belts are 1,1 mm thick as

the guiding blade pads have been adjusted to this size. If using

different size toothed belts, it will be necessary to proceed with a

new registration as follows:

- Loosen the screws ( B ) and loosen dowels (A ) widening the

passage between the plates.

- Loosen the dowels ( C ) and rotate the pins to widen the passage

between the bearings.

- Mount the new blade and rotate the hand wheel belt tensioner

until the relative dip-switch is activated.

- Tighten the dowels ( A ) and then loosen them to allow a play of

0,04 mm to ensure the smooth running of the blade and fasten

the screws ( B ).

- Rotate the pins until the bearings rest on the blade and block the

screws ( C ).

- Ensure that between the blade and the superior bearings there

are 0,2 - 0,3 mm of play; if necessary, loosen the screws ( D )

that block the heads and execute the necessary registration.

- the CUTTING SPEED and the TYPE of BLADE - combined

with a suitable lowering of saw frame - are of decisive impor-

tance for cutting quality and for machine performance (for

further details on this topic, see below in the chapter on “Mate-

rial classification and blade selection”).

- When starting to cut with a new blade, in order to safeguard its

life and efficiency, the first two or three cuts must be made

while exerting a slight pressure on the part, so that the time

taken to cut is about double the normal time (see below in the

chapter on “Material classification and blade selection” in the

section on

Blade running-in).

- Press the red emergency button ( 1 ) when there are conditions of

danger or malfunctions in general, so as to stop machine opera-

tion immediately.

A

B

A

8

160 BAR