Super, Description of the operating cycle – Dake Model TRAD 300 User Manual

Page 9

9

SUPER

SUPER

SUPER

SUPER

SUPER TRAD 300 MM

TRAD 300 MM

TRAD 300 MM

TRAD 300 MM

TRAD 300 MM

DESCRIPTION OF THE

OPERATING CYCLE

Before operating, all the main organs of the machine must

be set in optimum conditions (see the chapter on “Regulat-

ing the machine”).

6.1 - Starting up and cutting cycle

CUTTING CYCLE

-

Manual vice locking;

-

Manual sawframe downfeed;

-

Manual sawframe lift;

-

Manuale vice opening.

- Make sure the machine is not in emergency stop; if so, re-

lease the red mushroom push-button.

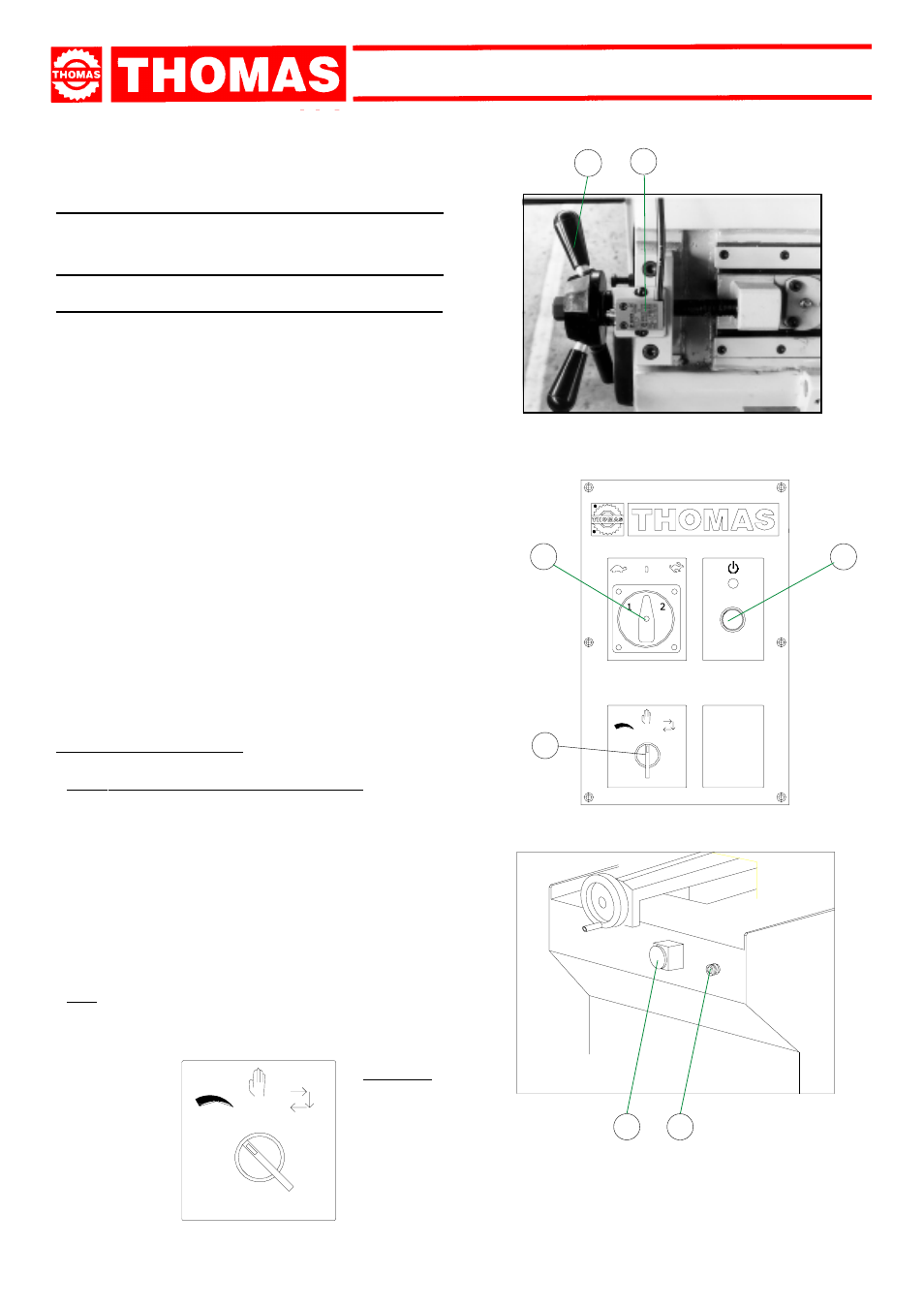

- Turn the blade tension Handwheel ( 2 ) clockwise untill the

microswitch button ( 3 ) is pressed down.

- Select the cutting speed on switch ( 5 ):

position 1 = 33 m/min

position 2 = 66 m/min

ATTENTION: Make sure that the vice has been positioned to

the far right or left of the countervice to avoid accidental impact

with the sawblade. Also make sure that the relevant lever has

been locked

(also see Chapter 7 paragraph 7.3).

- Place the piece to be cut inside the vice by moving jaw to

about 3 - 4 mm and lock with lever ( 8 pag. 11 ).

- Strike the start/reset push-button ( 6 ).

- Turn the selector ( 4 ) to the desired function mode:

Cutting cycle selection

MANUAL MODE WITH DOWNFEED DAMPER

- As you turn the selector ( 4 ) to the left

( see figure A ), you

can pull down the sawframe manually at the feed rate set on

the regulator ( 9 ).

- If you want to approach the sawframe to the workpiece quickly

( blade not started ), press the button located on top of the

trigger switch ( 6 - figure D ); as you release the button, the

sawframe stops.

- Press the trigger switch ( 7 - figure D ) to start the blade and

pull down the sawframe manually to cut the workpiece. The

motor will stop automatically as soon as you release the trigger

switch..

Note: the sawframe return spring ( 8 - figure E ) must be

tensioned as much as to counterbalance the weight of the

sawframe.

6

5

1

4

9

6

FIGURA A

2

3