Super – Dake Model TRAD 300 User Manual

Page 12

12

SUPER

SUPER

SUPER

SUPER

SUPER TRAD 300 MM

TRAD 300 MM

TRAD 300 MM

TRAD 300 MM

TRAD 300 MM

- Rotate the pins ( E - G ) until the bearings rest against the

blade as indicated in the figure and then secure the dowels ( I

) and nut ( H ).

- Make sure that between the blade and the upper teeth of the

pad ( L ) this is at least 0.2 - 0.3 mm of play; if necessary,

loosen the screws that fasten the blocks and adjust accord-

ingly.

7.3 - Vice

- The vice can be positioned either to the right or to the left of

the blade. Tight Lever ( 2 ) after positioning the vice to the far

right/left. The vice can slide very quickly by meand of the

handle ( 1 ); in case the the vice moves too loose along the

guide, tight the screws ( 3 ).

- Approach the vice jaw allowing 3-4 mm clearance between

jaw and material.

In case the blade needs to be replaced, make sure to always

install 0.9 mm thick blades for which the blade guide pads have

been adjusted. In the case of toothed blades with different thick-

nesses adjustment should be carried out as follows:

- Loosen nut ( C ), screw ( B ) and loosen dowel ( D ) widening

the passage between the pads.

- Loosen the nuts ( H ) and the dowels ( I ) and rotate the pins

( E - G ) to widen the passage between the bearings ( F ).

- Mount the new blade, place the pad ( A ) on the blade and,

loosening the dowel, allow a play of 0.04 mm for the sliding of

the toothed blade; lock the relative nut and screw ( B ):

7.5 - Cutting angle adjustment

- Unlock lever ( 11 ) and rotate the saw frame arm until you

reach mechanical stop and check if the index corresponds to

45°; if not operate on the set screws to make measures meet.

2

1

3

11

7.6 - Blade cleaning brush

It is an ideal accessory for the cleaning of the blade during the

cutting cycle. Periodically check the condition of the brush and if

necessary proceed to further adjustment to ensure cleaning of

the blade.

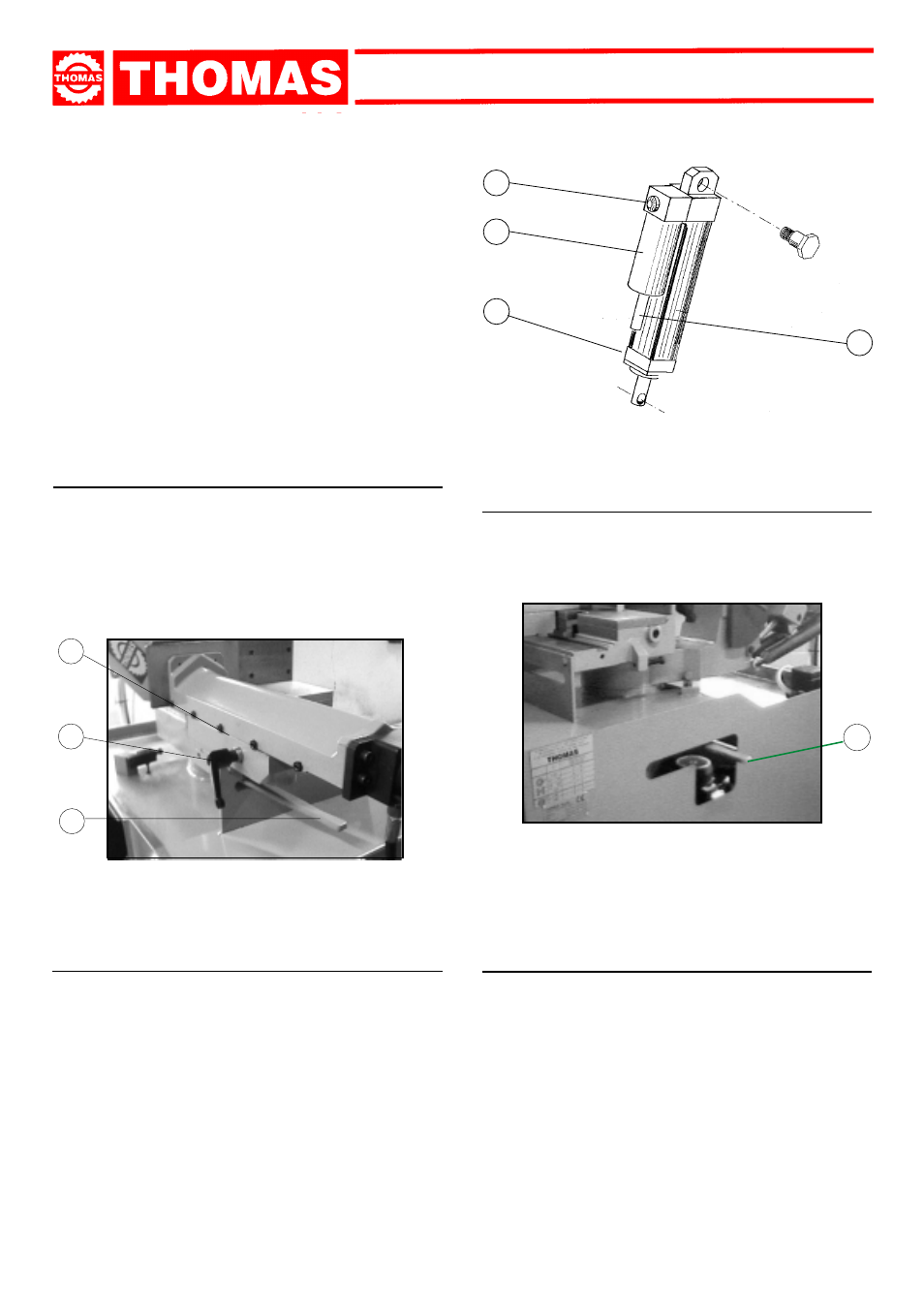

7.4 - Saw frame lowering control device

It is an accessory, ideal for the cutting of thin or STAINLESS

STEEL section bars, that determines a constant lowering and

consequently a good efficiency of the blade throughout the work

phase. By adjusting the ring nut on the base ( 9 ), this device

can be accommodated to the different situations and applica-

tions. Defectiveness in the control of the lowering may be caused

by the drop in braking power of the device due to the long-term

blow-by of the braking fluid.

Push rod (2) back into its seat and loosen plug (3). Use recom-

mended oil to top up oil tank (4) with the help of a syringe-type

pump. Bleed air, after having tightened plug (3) and loosen screw

(5) lightly until a little oil drip out; when this has been com-

pleted, secure the screw.

Use SHELL HYDRAULIC OIL 32 or similar.

2

3

5

4