0 care and maintenance – ARI Armaturen CONA S PN40 EN User Manual

Page 8

Page 8

Rev. 0040805004 2404

Operating and installation instructions

CONA

®

S - Ball float steam traps

7.0 Care and maintenance

Maintanance and maintenance-intervals have to be defined by the operator according to

the requirements.

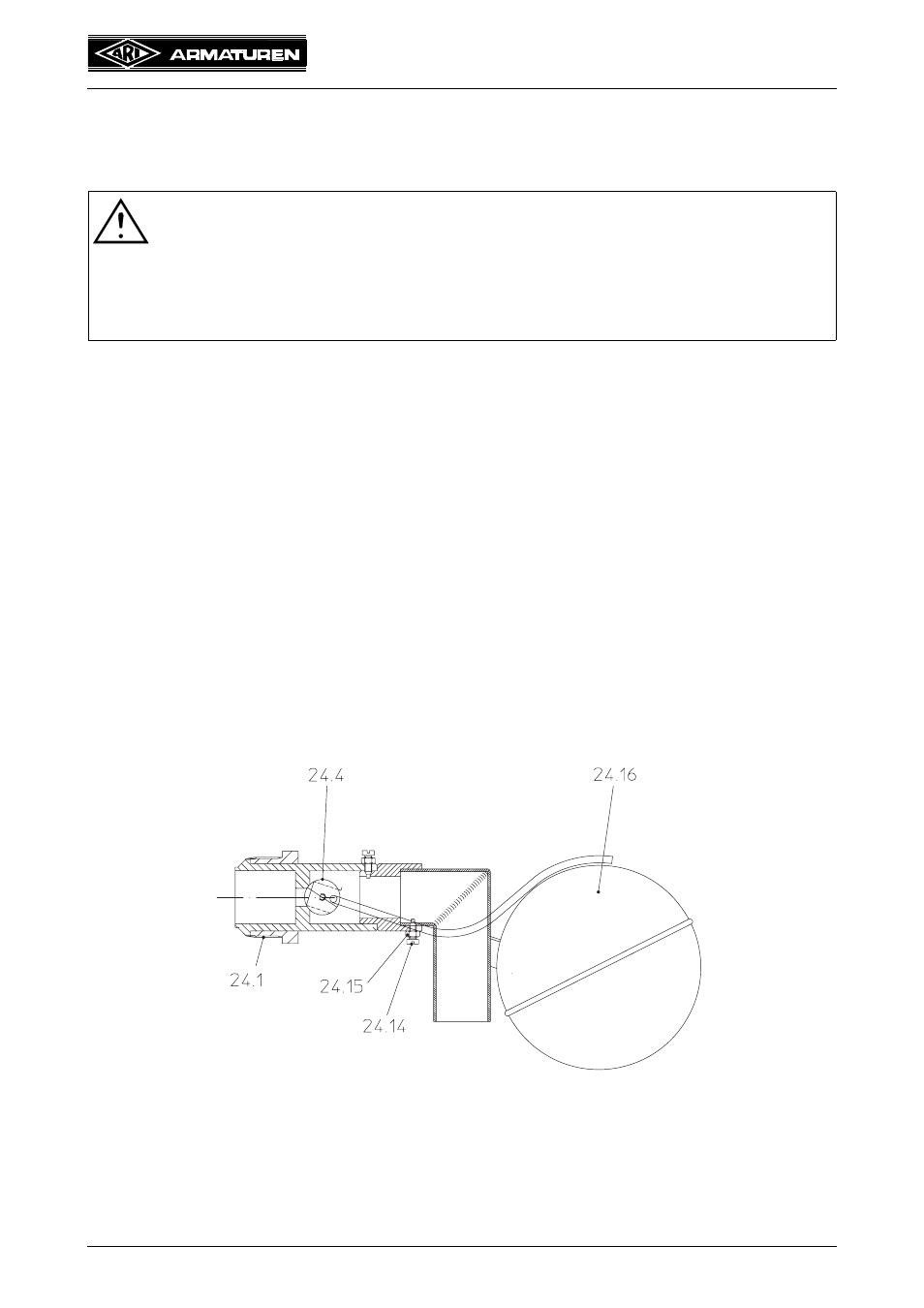

7.1 Cleaning / replacing controller assembly

(refer to Fig. 1 page 4- Fig. 3 page 7 and Fig. 4 page 8)

- Dismantle hood (Pos. 16) and intermediate flange by slackening hexagon nuts (Pos. 29).

- Remove dirt from body (Pos. 1) and hood (Pos. 16); tiny dirt particles can be removed by

flushing out the ducts and rinsing the body (Pos. 1).

- If necessary remove the float controller (Pos. 24) and clean separately or change float

controller.

- Unscrew hollow-core screw (Pos. 24.10) of float controller (Pos. 24) from body (Pos. 1).

- Pull complete float controller (Pos. 24) out to remove.

- Check lifting force of ball float (Pos. 24.16) by immersing the whole controller (Pos. 24) in

a water bath. When immersed in the water bath the ball float (Pos. 24.16) must float. If the

ball float (Pos. 24.16) sinks (i.e. goes under) the complete controller (Pos 24) should be

replaced.

- Replace sealing rings (Pos. 17).

- Assemble in reverse order (see 7.4).

ATTENTION !

- refer to item 10.0 and 11.0 prior to dismantling and repair work!

- refer to item 6.0 before restarting the plant !

Prior to installation, threads and seal faces should be coated with temperature-

stable lubricant (e.g. “OKS Anti-Seize Paste” white/metal-free for PN16-40 or

“Rivolta” lubricant and parting agent silver for PN63 onwards).

Fig. 4: Controller, cpl.