0 troubleshooting table – ARI Armaturen STEVI 426 EN User Manual

Page 14

Page 14

Rev. 0040314001 0410

Operating and installation instructions

Straight through control valves - STEVI

®

425 / 426

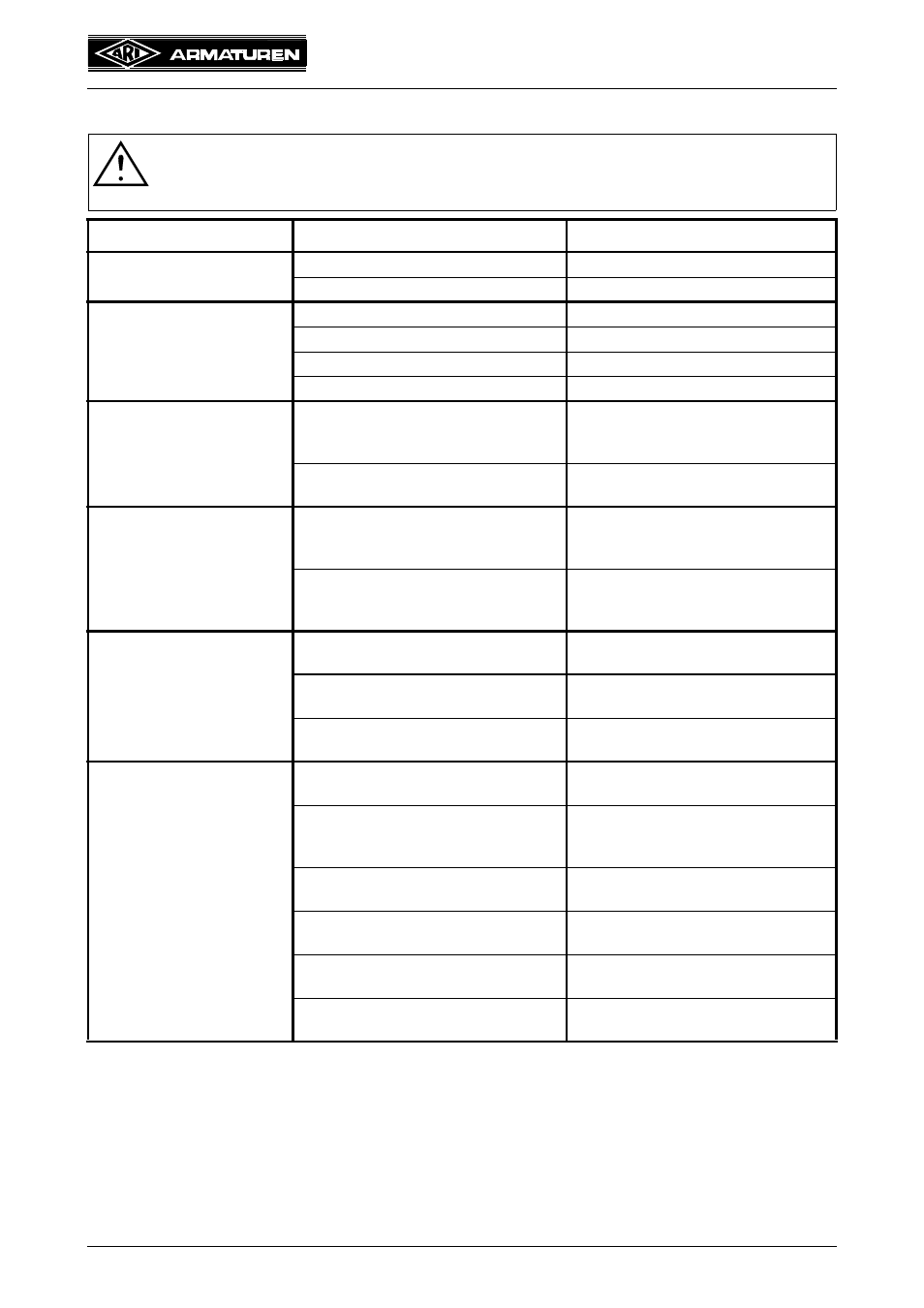

9.0 Troubleshooting table

ATTENTION !

- read item 10.0 and 11.0 prior to dismantling and repair work!

- read item 6.0 before restarting the plant !

Fault

Possible cause

Corrective measures

No flow

Valve closed

Open valve (using actuator).

Flange covers not removed

Remove flange covers.

Little flow

Valve not sufficiently open

Open valve (using actuator).

Dirt sieve clogged

Clean / replace sieve.

Piping system clogged

Check piping system.

Kvs value of valve unsuitable

Fit valve with higher Kvs value.

Valve stem moves in jerks.

Stuffing box sealing too tight (for valves

with graphite packings)

Slacken stuffing box gland with nut

(pos. 18 resp. 20.29);

Valve must nor start leaking!

Valve plug slightly seized owing to

solid dirt particles

Clean internals, smooth rough spots.

Valve stem or plug cannot be

moved.

Seating and plug are clogged with dirt;

especially with V-port and perforated

plugs

Clean seating and plug with suitable

solvent

Valve plug seized in seating or guide

owing to deposits or dirt in medium

Replace plug and seating; use parts

made from different material if neces-

sary; refer to item 7.2

Valve stem leaking.

Defective stem sealing in valves with

EPDM stem sealing

Replace stem sealing;

refer to item 7.1.1

Stuffing box gland too slack in valves

with stuffing box packings

Tighten stuffing box gland with nuts

(pos. 22) or repack; refer to item 7.1.2

Bellows defective in valves with bellow

seal

Replace bellows unit (pos. 20.3);

refer to item 7.1.3

Leakage too high when

valve is closed.

Sealing surfaces of plug eroded or

worn

Replace plug; refer to item 7.2

Sealing edge of seating damages or

worn

Grind the seat resp. replace seat ring;

refer to item 7.2,

fit dirt sieve if necessary.

Piston sealing ring worn

(pressure-relieved valves)

Replace sealing ring; refer to item

7.2.2

Seating and/or plug dirty

Clean internals of valve; fit dirt sieve if

necessary

Pneumatic actuator not completely

vented; spring force not fully effective

Vent actuator air chamber completely.

Actuator not powerful enough

Install more powerful actuator;

check service data