0 care and maintenance, 0 troubleshooting, 0 troubleshooting table – ARI Armaturen CHECKO-D DN 125-350 EN User Manual

Page 7: Operating and installation instructions checko

Rev. 0040106001 2613

Page 2-7

Operating and installation instructions

CHECKO

®

-D DN 125-350

7.0 Care and maintenance

Maintanance and maintenance-intervals have to be defined by the operator according to

the requirements.

8.0 Troubleshooting

In the event of malfunction or faulty operating performance check that the installation and

adjustment work has been carried out and completed in accordance with these Operating

Instructions.

If malfunctions cannot be eliminate with the help of the following table

“9.0 Troubleshooting table”, the supplier or manufacturer should be consulted.

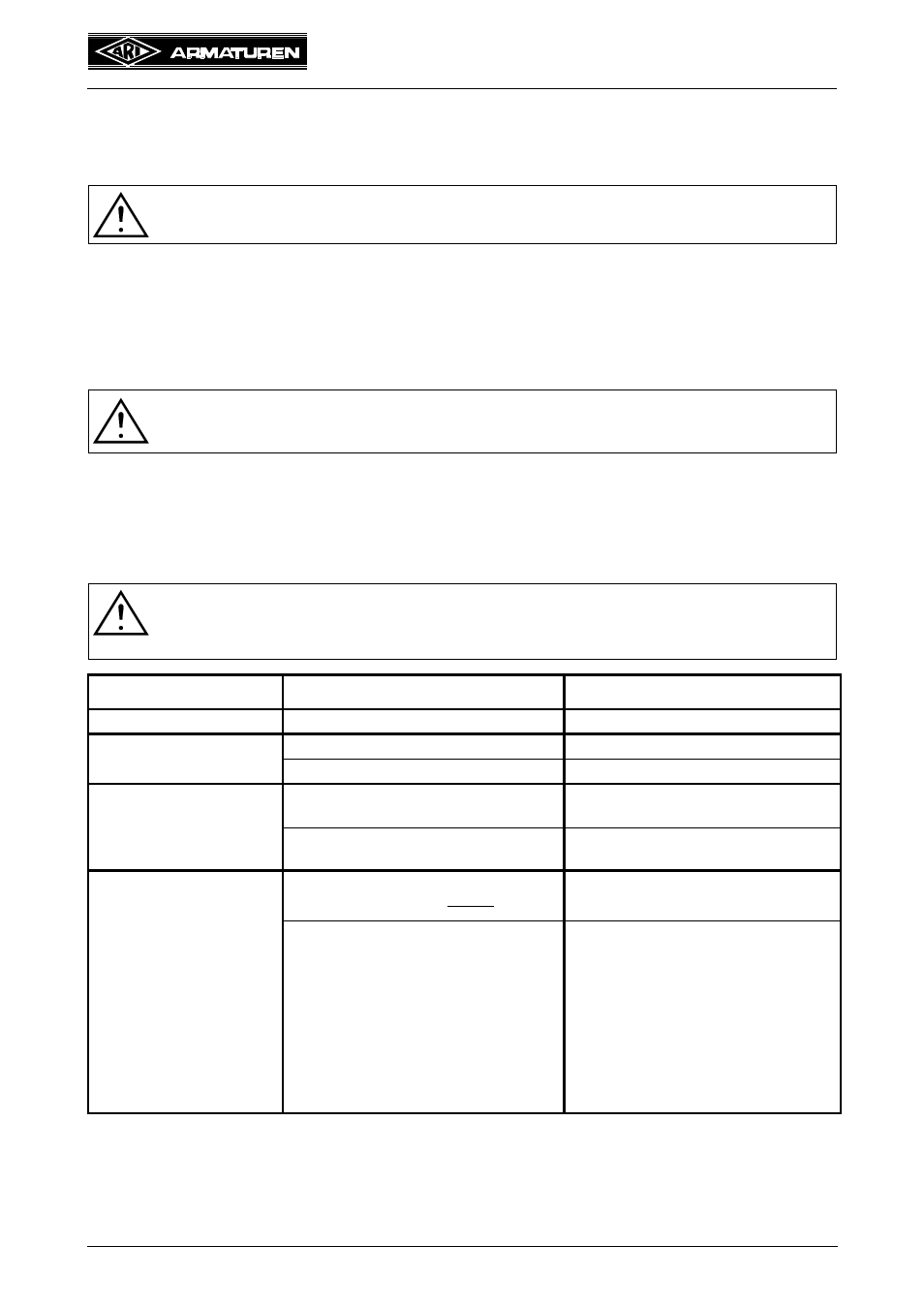

9.0 Troubleshooting table

ATTENTION !

- See point 10.0 before dismantling the valve.

-

ATTENTION !

It is essential that the safety regulations are observed when identifying faults.

ATTENTION !

- read point 10.0 and 11.0 prior to dismantling and repair work!

- read point 6.0 before restarting the plant !

Fault

Possible cause

Corrective measures

No flow

Wrong flow direction

Correct the installation

Little flow

Dirt sieve clogged.

Clean / replace sieve.

Piping system clogged.

Check piping system.

Leakage across valve seat. Body (pos.1) / valve plate (pos. 8) dam-

aged by foreign particles (Fig. 1)

Replaced valve, consult supplier/manu-

facturer.

Medium contaminated

(suspended solids).

Clean valve.

Install dirt screen upstream of valve.

Rattling / banging

of the plug resp. of the

valve plate

Nominal diameter of the valve in compli-

ance to the flow rate is too big

Choose smaller nominal diameter

- high flow turbulences;

- the check valve is mounted directly by

a centrifuged pump;

- behind pressure reduction stations;

- behind pipe elbows;

- in compact plants;

- expansion joints are missing;

- the pump is not mounted on a damper;

- there is no flow stabilizing pipe length;

- there is no start-up bypass line

Alter the system