0 care and maintenance – ARI Armaturen Metallic sealing EN User Manual

Page 7

Operating and installation instructions

Change over valve

Rev. 0040110000 0410

Page 7

7.0 Care and maintenance

Maintanance and maintenance-intervals have to be defined by the operator according to

the requirements.

- Observe safety instructions!

- Keep the spindle well greased!

- Lubricant:

e.g. Klüberpaste HEL 46-450 (at valves for oxygen:

Klüberalfa YV93-302)

to order at:

Klüber Lubrication München KG, Postfach 701047, D-81310 München

or a lubricant wich is suitable for the application.

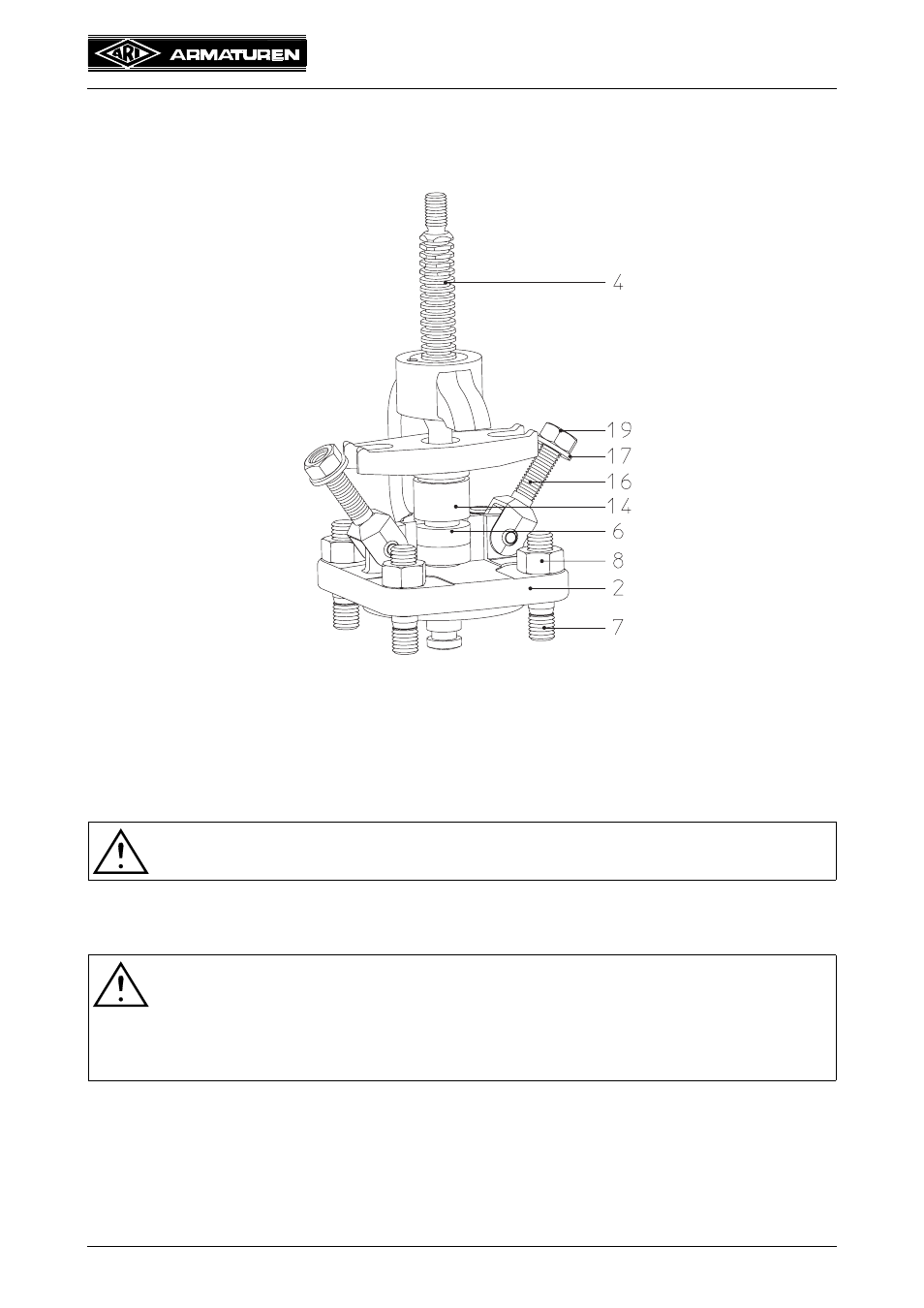

- If the valve spindle (pos. 4) leaks, gradually tighten the stuffing box seal (pos. 6) evenly in

increments by means of the hex. nuts (pos. 19) until leaking stops.

- Replace stuffing box packings only after the system has cooled down and the pressure in

the plant has been relieved.

In the case of corrosive or aggressive mediums, drain and ventilate the valve before

replacing the packing.

fig. 3: Pattern with hinged bolts

ATTENTION !

Pay attention, that the lubricant is suitable for the media.

ATTENTION !

- Retighten the stuffing box packing if required and re-pack it in good time.

- For safety reasons we recommend that valves only be repacked when

depressurised.

- Refer to point 10.0 and 11.0 before dismantling the valve.