Standard performance – Power Jacks C-Series User Manual

Page 9

www.powerjacks.com

9

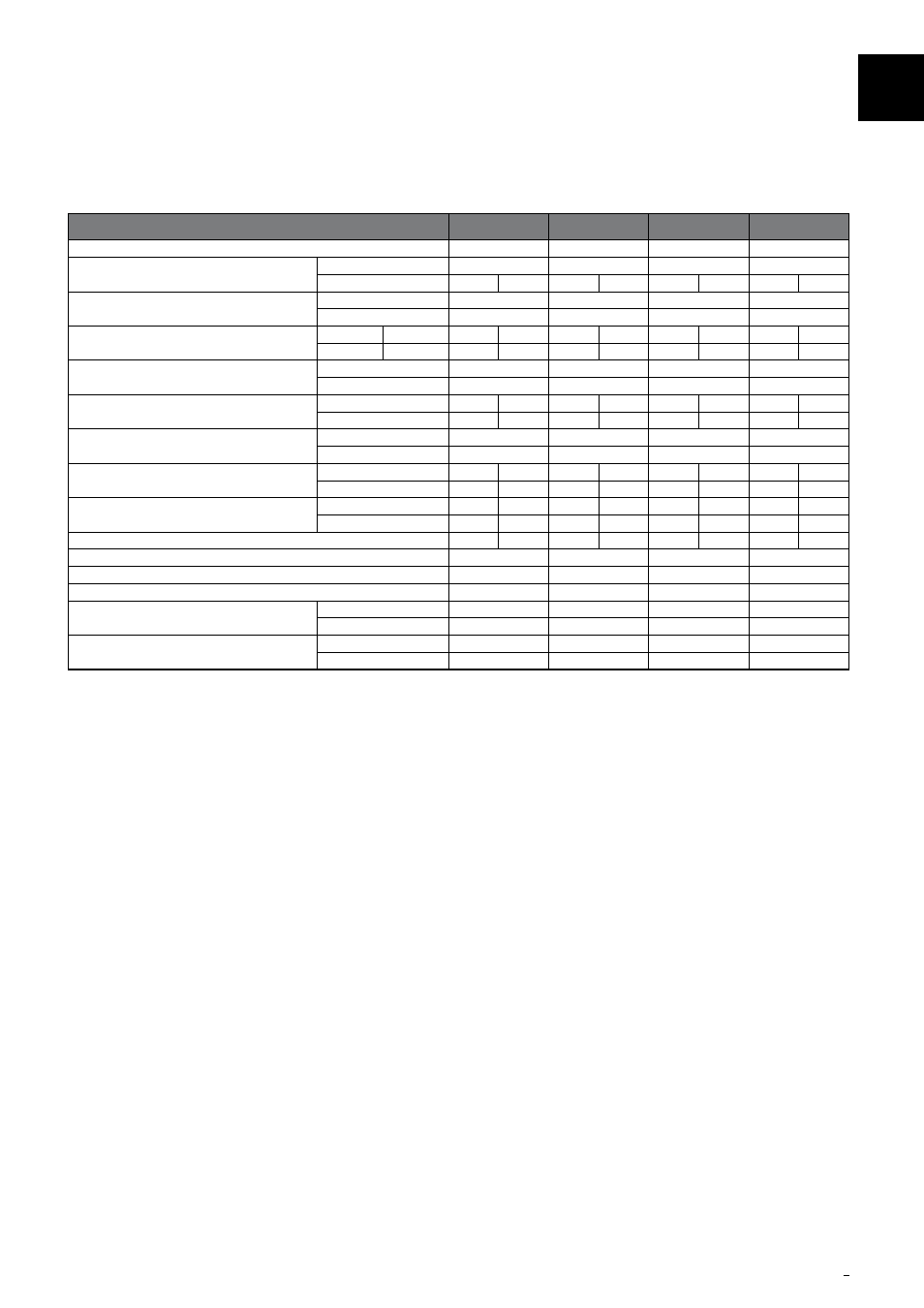

Screw Jack Model

4

CM-010

CM-025

CM-050

CM-100

Capacity (kN)

10

25

50

100

Lead Screw

1

Diameter (mm)

20

30

40

55

Lead (mm)

5

10

6

12

9

18

12

24

Gear Ratios

Option 1

5:1

6:1

6:1

8:1

Option 2

20:1

24:1

24:1

24:1

Turn of worm for travel of lead screw

Option 1

1 Turn

1mm

2mm

1mm

2mm

1.5mm

3mm

1.5mm

3mm

Option 2

4 Turn

1mm

2mm

1mm

2mm

1.5mm

3mm

2mm

4mm

Maximum Input Power (kW)

Option 1

0.375

1.5

3

3.75

Option 2

0.19

0.375

0.55

1.125

Start up torque at full load (Nm)

2

Option 1

6.8

9.4

19.8

26.4

56.0

76.0

115.9

156.6

Option 2

3.0

4.1

8.7

11.7

25.5

34.7

60.5

81.9

Maximum Through Torque (Nm)

7

Option 1

20.4

59.4

168.0

347.7

Option 2

9.0

26.1

76.5

181.5

Static Efficiency

3

Option 1

0.236

0.339

0.201

0.302

0.213

0.314

0.206

0.305

Option 2

0.133

0.192

0.113

0.171

0.117

0.172

0.132

0.195

Dynamic Efficiency

3

Option 1

0.306

0.424

0.264

0.383

0.281

0.398

0.272

0.388

Option 2

0.194

0.268

0.167

0.242

0.172

0.244

0.190

0.271

Lead Screw Restraining Torque (Nm)

5

22

30

76

102

210

290

575

780

Worm Shaft Radial Load (N)

6

325

380

740

1000

Maximum Input Speed (rpm)

1800

1800

1800

1800

Gear Case Material

Aluminium

SG Iron

SG Iron

SG Iron

Weight (kg) - stroke = 150mm

Translating

3.0

8.3

19.5

36.0

Rotating

3.1

8.7

20.2

40.2

Weight (kg) - per extra 25mm

Translating

0.11

0.21

0.32

0.57

Rotating

0.05

0.11

0.19

0.36

Notes:

1.

All metric machine screws have a trapezoidal thread form.

2.

For loads of 25% to 100% of screw jack capacity, torque requirements are approximately proportional to the load.

3.

Efficiency values for standard grease lubricated worm gear box and lifting screw.

4.

All C-Series screw jacks have grease lubricated gearbox and lead screw as standard.

5.

Torque required to prevent the lead screw or lead nut from rotating if no anti-rotation device fitted.

6.

Radial force applied midway along worm shaft key at 90º to key.

7.

Maximum transmittable torque through worm shaft, not through gear set.

Standard Performance

3