Product code, 0 example – Power Jacks C-Series User Manual

Page 8

8

www.powerjacks.com

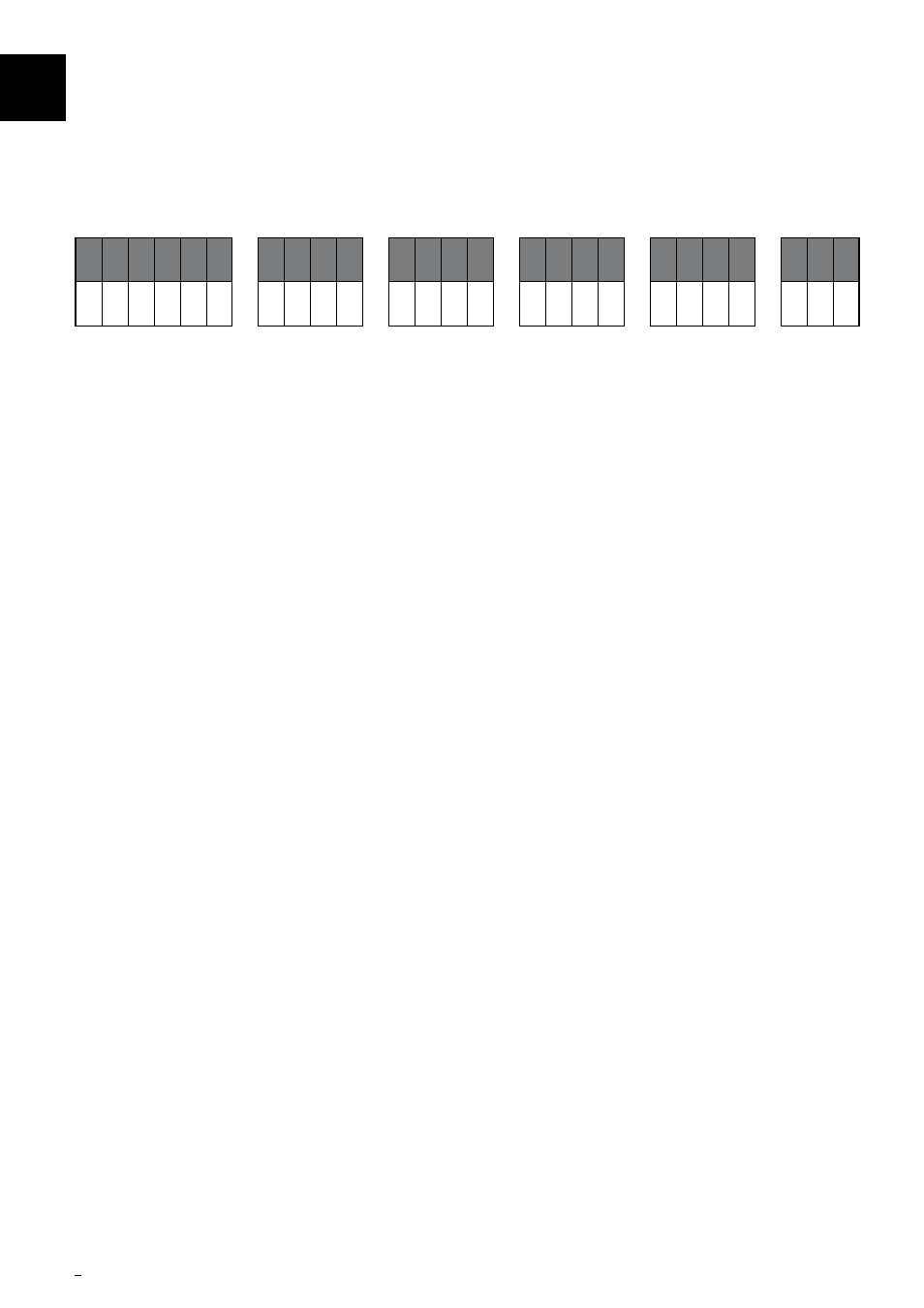

2.0 Example

1

2

3

4

5

6

-

7

8

9

10

-

11

12

13

14

-

15

16

17

18

-

19

20

21

22

-

23

24

25

C

M

T

0

2

5

-

0

7

5

0

-

T

B

1

1

-

0

0

P

T

-

0

0

0

B

-

3

P

0

Product Code

[1] - Screw Jack Type

C = C-Series Screw Jack

[2] - Screw Type

M = Machine Screw

[3] – Screw Configuration

T = Translating Screw

R = Rotating Screw

[4,5,6] – Capacity (kN)

010 = 10kN

025 = 25kN

050 = 50kN

100 = 100 kN

[7,8,9,10] – Stroke (mm)

e.g. 0750 = 750mm

[11] – End Type

E = Threaded End

C = Clevis

T = Top Plate

F = Fork End

R = Rod End

A = Plain End

#9

P = Pilot End

#1

N = No Pilot

#1

[12] – Gearbox Mounting

B = Base Mount

T = Trunnion Mount

Standard #2

U = T + Trunnion Feet

X = Trunnion Mount 90°

#3

Y = X + Trunnion Feet

[13] – Lead Screw Pitch

1 = Option 1 Lead

#4

2 = Option 2 Lead

#4

3 = Option 1 Left Hand

#5

4 = Option 2 Left Hand

#5

[14] – Gear Ratio

1 = Option 1 ratio

2 = Option 2 ratio

[15] – Features

0 = None

K = Anti-Rotation (keyed)

C = Secondary Guide

R = Anti-Backlash

Y = Anti-Backlash & Anti-

Rotation (keyed)

H = Double Hub Nut

#1

[16] – Cover Pipe

0 = Cover Pipe

N = No Cover Pipe

[17] – Stop Nut

0 = No Stop Nut

P = Full Power Stop Nut

[18] – Safety Nut

0 = No Safety Nut

T = Safety Nut Tension

C = Safety Nut Compression

[19] – Worm Shaft Type

0 = Standard Material

N = Nickel Plated

C = Chrome Plated

S = Stainless Steel

[20] – Worm Shaft Ends

0 = Both

L = Left Hand Side Only

R = Right Hand Side Only

[21] – Lead Screw Material

0 = Standard

S = Stainless Steel

L = Large Diameter

#1 #8

T = Large Diameter Stainless

Steel

#1 #8

[22] – Lead Screw Cover

0 = None

B = Bellows Boot (fabric)

[23] – Drive

0 = Side Bolt Holes - Both

Sides

M = Motor

#6, #8

B = Brake Motor

#6, #8

H = Hand Wheel

1 = Side Bolt Holes - LHS

2 = Side Bolt Holes - RHS

3 = No Side Bolt Holes

A = Motor Adapter

#6, #8

[24] – Limit Switch

#7, #8

0 = None

L = Electro-Mechanical Limit

Switch

R = Rotary Cam Limit Switch

P = Proximity Sensor

[25] – Extra Design

#8

0 = None

S = Design Notes

Notes:

#1. Rotating screw models only.

#2. Trunnions on same side as worm shaft (standard).

#3. Trunnions at 90° to worm shaft.

#4. Standard right hand thread form. Worm shaft turns clockwise to extend screw.

#5. Left hand thread form. Worm shaft turns anti-clockwise to extend screw.

#6. Includes motor adapter and coupling. IEC motor adapter is standard.

#7. Limit switch mounting included.

#8. Design notes required to detail device/item specification.

#9. Plain end “A” has same dimensions as “E - threaded end” except no thread form.

2