Operation – Power Jacks C-Series User Manual

Page 17

www.powerjacks.com

17

5

Operation

5.2.11

Shock Loads on a Screw Jack

Shock loads should be eliminated or reduced to a minimum, if they cannot be avoided, the screw

jack model selected should be rated at twice the required static load.

For severe shock load applications, use the E-Series, S-Series or M-series screw jacks, the load

bearings here can be replaced with heat-treated steel thrust rings which is an option available

from Power Jacks. Note this will increase the input torque by approximately 100%.

5.2.12 Axial Backlash in a Screw Jack

5.2.12.1 Backlash in Standard Machine Screw Jacks

Machine screw jacks have backlash due not only to normal manufacturing tolerances, but to the

fact that there must be some clearances to prevent binding and galling when the screw jack unit

is under load. Usually, the axial backlash is not a problem unless the load on the screw jack unit

changes between compression and tension. If a problem does exist, then a unit with the anti-

backlash feature should be considered.

5.2.12.2 Screw Jacks with the Anti-Backlash Device

The anti-backlash device reduces the axial backlash between the lead screw and nut assembly

to a regulated minimum. As the backlash will increase as the lead screw thread on the gear

wears the anti-backlash device can be adjusted to remove this normal condition.

5.2.13

How the Anti-Backlash Device Works

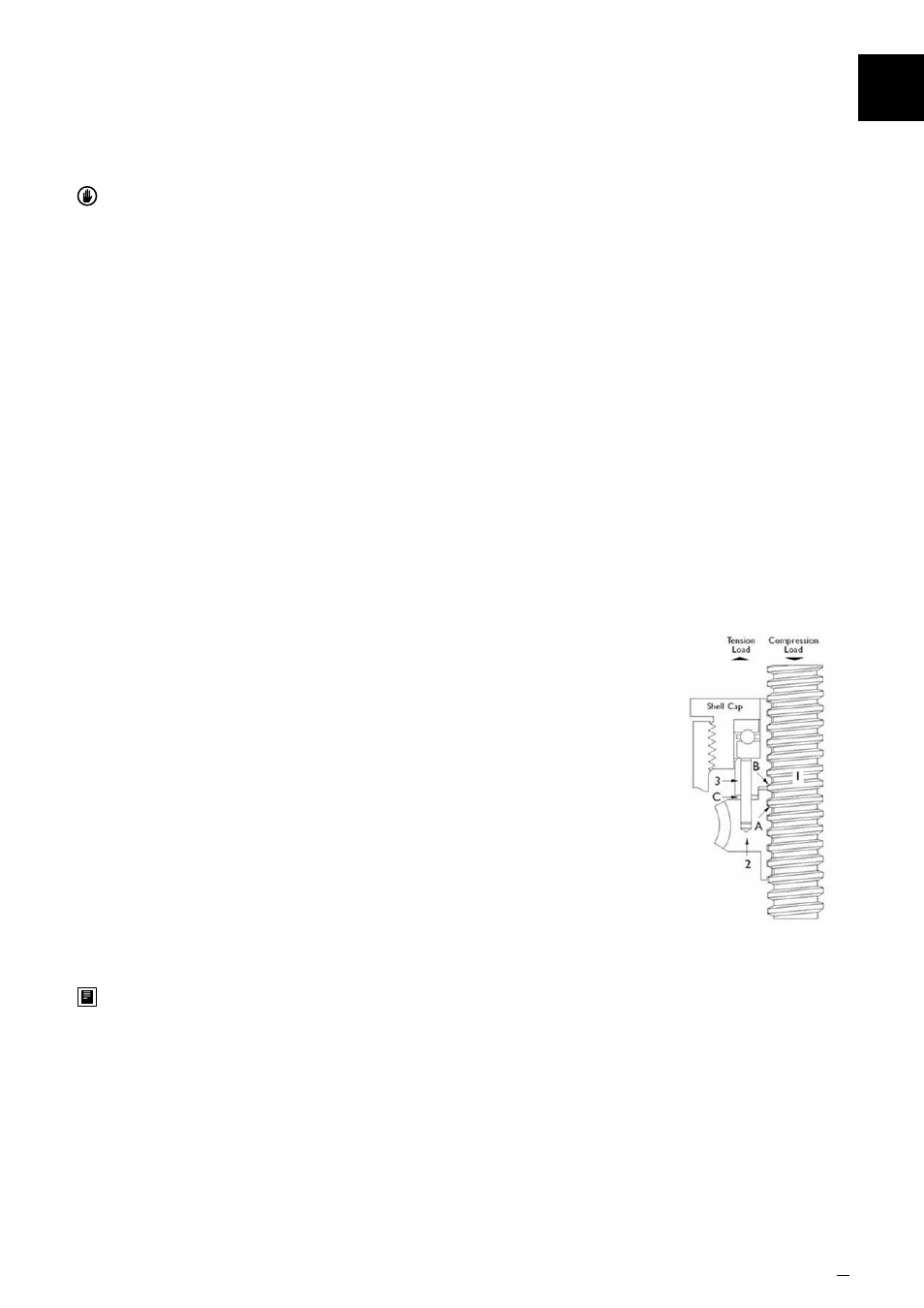

When the screw (1) is under a compression load, the bottom of its

thread surfaces are supported by the top thread surfaces of the worm

gear (2) at point (A). The anti-backlash nut (3), being pinned to the

worm gear and floating on these pins and being adjusted downward

by the shell cap, forces its bottom thread surfaces against the upper

thread surfaces of the lifting screw at point (B). Thus, backlash

between worm gear threads is reduced to a regulated minimum.

When wear occurs in the worm gear threads and on the load carrying

surfaces of the lifting screw thread, the load carrying thickness of the

worm gear thread will be reduced. This wear will create a gap at point

(B) and provide backlash equal to the wear on the threads.

Under compression load, the lifting screw will no longer be in contact

with the lower thread surface of the anti-backlash nut. Under this

condition, backlash will be present when a tension load is applied.

The anti-backlash feature can be maintained simply by adjusting the shell cap until the desired

amount of backlash is achieved.

To avoid binding and excessive wear do not adjust lifting screw backlash to less than 0.025mm

(0.001”). This will reduce the calculated separation (C) between the anti-backlash nut and worm

gear and will reduce the backlash between the worm gear threads and the lifting screw to the

desired minimum value.

When separation (C) has been reduced to zero, wear has taken place. Replace the worm gear

(2) at this point. This feature acts as a built in safety device which can be used to provide wear

indication for critical applications.

5.2.14

Column Strength of the Screw Jack

Column strength of a screw is determined by the relationship between the screw length and its

diameter. For column strength charts consult product literature or Power Jacks.