Installation requirements, Gas pressure requirements, Supply gas line – State SUF 130 500 User Manual

Page 13: Supply gas regulator, Power supply

13

generally provide good water heater operation. Some addition

adjustment maybe required later to maintain a steady gas

supply pressure.

4. When installing multiple water heaters in the same gas supply

system it is recommended that individual positive lock-up gas

pressure regulators be installed at each unit.

power supply

The water heaters covered in this manual require a 120 VAC,

1Ø (single phase), 60Hz, 15 amp power supply and must also

be electrically grounded in accordance with local codes or, in the

absence of local codes, with the National Electrical Code, ANSI/

NFPA 70 or the Canadian Electrical Code, CSA C22.1.

power fluctuations and electrical noise

The water heater’s control system requires a source of stable

clean electricity for proper operation. Connecting the water heater

to a branch circuit that is subject to fluctuations in voltage level or

electrical line noise such as EmI (electro magnetic interference)

or rFI (radio frequency interference) may cause erratic control

system operation and malfunction.

A high quality power supply filter/suppressor such as the Kleen

Line model SELF/T-10 Series SC-L or equivalent must be

installed if the above conditions exist. Call the technical support

phone number listed on the back cover of this manual for more

information.

note: malfunctions caused by the power supply and the costs

to install power supply filters are not covered under the limited

warranty.

dedicated power wiring and breakers

Dedicated power supply wires, ground wiring and dedicated

circuit breakers often prevent electrical line noise and should be

considered when installing the water heater.

polarity sensitiVe

The control system on the water heaters covered in this manual

is polarity sensitive; electronic flame sensing requires correct

polarity. The control system is programmed to monitor the

incoming power supply. If the Hot and Neutral wires in the 120

VAC power supply are reversed, the control system will declare

a Fault condition and lock out, heating operation will be disabled

until the power supply is correctly wired. The control system will

display the “AC reversed” Fault message on the LCD.

See Electrical Wiring on page 39 for installation instructions.

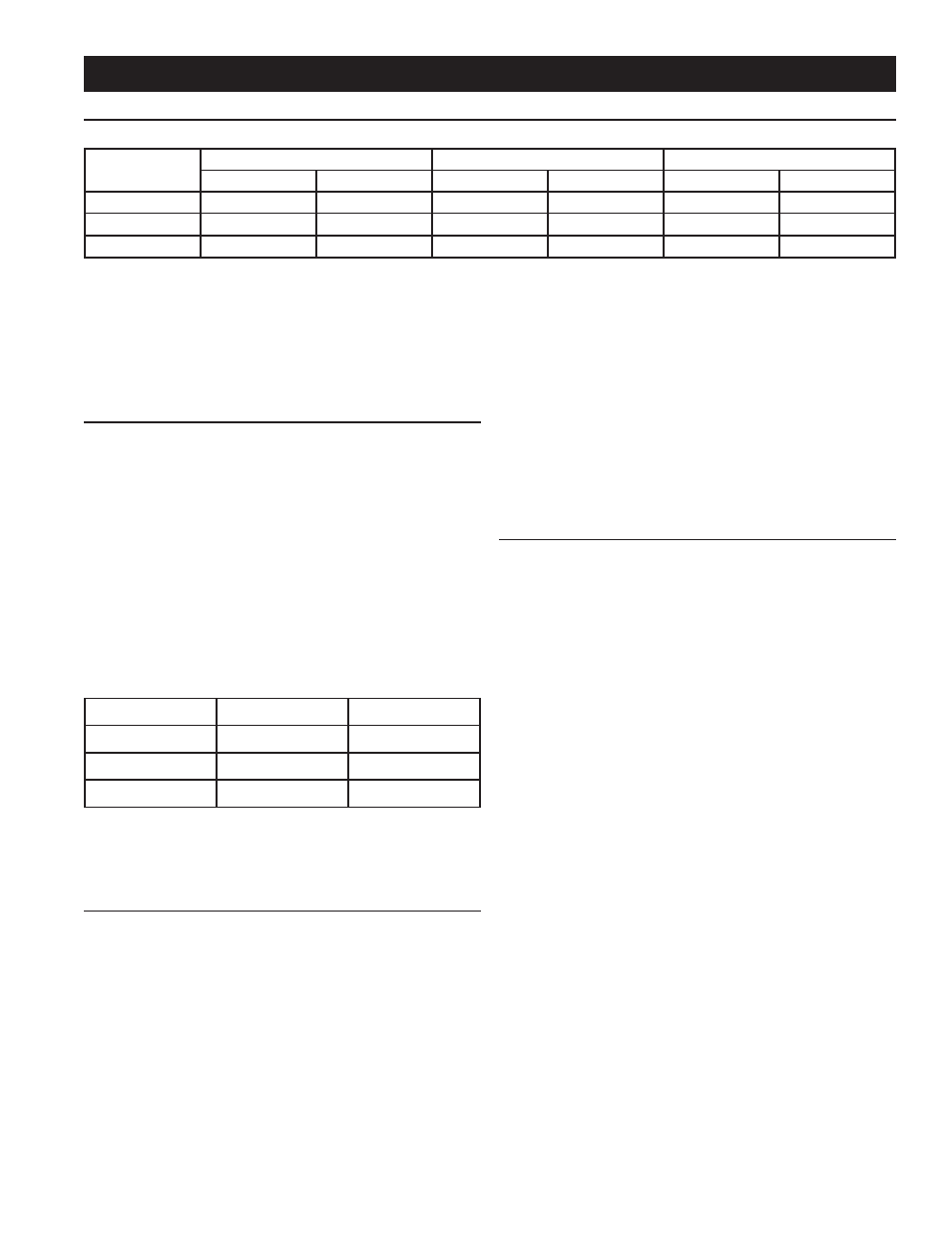

table 4

moDEl

*mANIFolD PRESSuRE

†mINImUm SUPPLy PrESSUrE

‡mAxImUm SUPPLy PrESSUrE

NATuRAl gAS

PRoPANE gAS

NATuRAl gAS

PRoPANE gAS

NATuRAl gAS

PRoPANE gAS

SuF 130 300

4” W. C. (1.0 kPa)

10” W. C. (2.49 kPa)

5.2” W. C. (1.29 kPa)

11” W. C. (2.74 kPa)

10” W. C. (2.49 kPa)

12” W. C. (2.99 kPa)

SuF 130 400

N/A

10” W. C. (2.49 kPa)

5.2” W. C. (1.29 kPa)

11” W. C. (2.74 kPa)

10” W. C. (2.49 kPa)

12” W. C. (2.99 kPa)

SuF 130 500

N/A

10” W. C. (2.49 kPa)

5.2” W. C. (1.29 kPa)

11” W. C. (2.74 kPa)

10” W. C. (2.49 kPa)

12” W. C. (2.99 kPa)

* manifold gas pressure; reading can only be taken while gas is flowing. reading taken should be ± 0.3” W. C. of the listed value. These water heaters are certified for

use without modification for altitudes up to 10,000 feet. For elevations above 10,000 feet (3,048 meters) see High Altitude Installations on page 52.

† minimum supply gas pressure; readings are taken while gas is not flowing (static pressure) AND while gas is flowing (dynamic pressure). Supply pressure must never

fall below the minimum values. Supply gas pressures should be measured with all gas fired appliances connected to a common main firing at full capacity. If supply

pressure drops more than 1.5” W. C. as gas begins to flow the supply gas system (gas line/regulator) may be restricted or undersized. See Table 5 and the Supply

Gas regulator requirements below. See Supply Gas Line Installation on page 37 and Supply Gas regulator on page 13 for sizing and installation instructions also.

‡ maximum supply gas pressure; reading are taken while gas is not flowing (static pressure) AND while gas is flowing (dynamic pressure). Supply pressure must never

exceed this maximum value.

supply gas line

The high efficiency water heaters covered in this manual require an

adequate volume of fuel gas for proper operation. A lack of fuel gas

volume can lead to ignition failure, rough starting and rough operation.

Increasing the supply gas pressure DoES NoT necessarily increase

the volume of gas supplied to the water heater and must remain

below the maximum supply gas pressures shown in Table 4.

The minimum supply gas line sizes shown in Table 5 must be

observed on all installations to help insure an adequate volume

of fuel gas is provided. Do NoT use flexible gas piping.

Supply gas lines serving more than one appliance may require

larger sizes than what is shown in Table 5. See Gas Line Sizing

on page 37.

minimum supply gas line siZe

table 5

moDEl

*NATuRAl gAS

PRoPANE gAS

SuF 130 300

1 1/4” NPT

1 1/4” NPT

SuF 130 400

1 1/4” NPT

1 1/4” NPT

† SuF 130 500

1 1/2” NPT

1 1/4” NPT

† Note that SUF 130 500 natural gas models require a 1 1/2” minimum supply

gas line size. Depending on the installed equivalent length, and/or the number

of appliances connected, the supply gas line size may have to be increased

beyond the minimum required sizes shown in this table - see Gas Line Sizing

on page 37.

supply gas regulator

The maximum allowable gas supply pressure for this water

heater is 10.0” W. C. (2.49 kPa) for natural gas and 12.0” W.

C. (2.99 kPa) for propane gas. Install a positive lock-up gas

pressure regulator in the gas supply line if inlet gas pressure can

exceed these pressures at any time.

If a positive lock-up regulator is required follow these instructions:

1. Positive lock-up gas pressure regulators must be rated at or

above the input Btu/hr rating of the water heater they supply.

2. Positive lock-up gas pressure regulator(s) should be installed

no closer than 3 feet (1 meter) and no farther than 8 feet (2.4

meters) from the water heater’s inlet gas connection.

3. After installing the positive lock-up gas pressure regulator(s)

an initial nominal supply pressure setting of 7.0” W.C. while

the water heater is operating is recommended and will

installation reQuirements

gas pressure reQuirements