Installation – State PCE 120 2ORTA User Manual

Page 9

9

InstallatIon

reQuIred abIlIty

Installation and service of this water heater requires ability equivalent

to that of a qualified installer or service agency (page 2) in the

field involved. Plumbing and electrical work is required.

General

The installation must conform with these instructions and the local

code authority having jurisdiction and the requirements of the power

company. In the absence of local codes, the installation must comply

with the latest editions of the National Electrical Code, NFPA 70 or

the Canadian Electrical Code CSA C22.1. The National Electrical

Code may be ordered from: National Fire Protection Association,

1 Batterymarch Park, Quincy, MA 02269. The Canadian Electrical

Code is available from the Canadian Standards Association, 8501

East Pleasant Valley Road, Cleveland, OH 44131.

Do

not test electrical system before heater is filled with water, follow

the START UP procedure in the OPERATION section of this manual.

The principal components of the heater are identified in the

Features and Components illustrations on page 7.

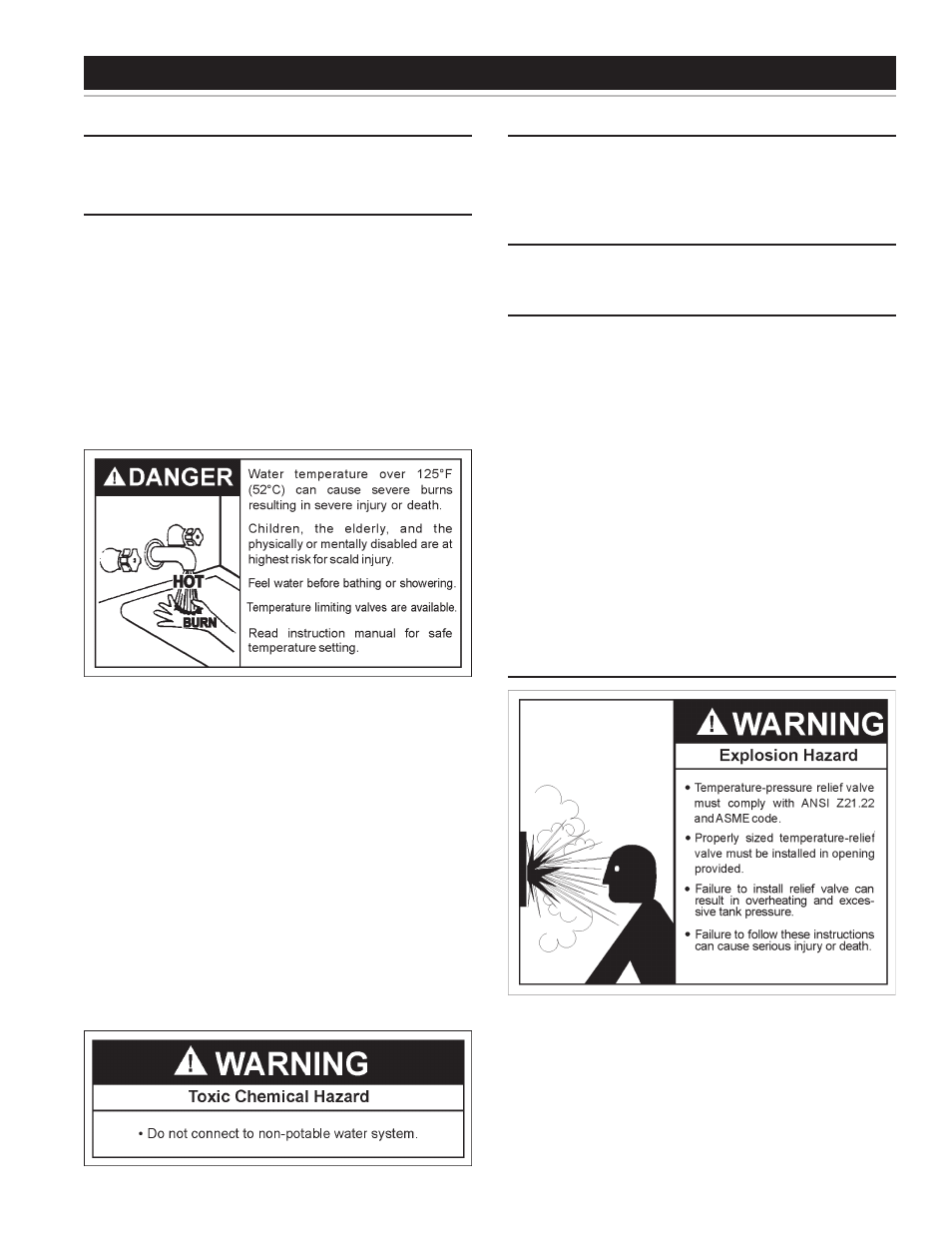

MIXING VALVE USAGE:

Water heaters are intended to produce hot water. Water heated to

a temperature which will satisfy space heating, clothes washing,

dish washing, cleaning and other sanitizing needs can scald and

permanently injure you upon contact. Some people are more likely

to be permanently injured by hot water than others. These include

the elderly, children, the infirm, or physically/developmentally

disabled. If anyone using hot water in your home fits into one of

these groups or if there is a local code or state law requiring a

maximum water temperature at the hot water tap, then you must

take special precautions. In addition to using the lowest possible

temperature setting that satisfies your hot water needs, a means

such as a

MIXInG ValVe, should be used at the hot water taps

used by these people or at the water heater.

MIXInG ValVes for reducing point of use temperature are available

and are to be set at a maximum of 125 degree F. Consult a qualified

installer or service agency. Follow all manufacturer’s Instructions

for installation of these valves. Before changing the factory setting

on the thermostat, read the “Temperature Regulation” section in

this manual.

contaMInated water

This water heater shall not be connected to any heating system(s)

or component(s) used with a non-potable water heating appliance.

Toxic chemicals, such as those used for boiler treatment shall not

be introduced into this system.

cIrculatInG puMp

Field installed circulating pumps should be of all bronze

construction.

InsulatIon blankets

Insulation blankets are available to the general public for

external use on electric water heaters but are not necessary with

this product. The purpose of an insulation blanket is to reduce

the standby heat loss encountered with storage tank heaters.

Your water heater meets or exceeds the EPACT and ASHRAE/

IES 90.1 standards with respect to insulation and standby loss

requirements, making an insulation blanket unnecessary.

Should you choose to apply an insulation blanket to this heater,

you should follow these instructions below. Failure to follow

these instructions can result in fire, serious personal injury,

or death.

• Do not cover the temperature and pressure relief (T & P) valve

with an insulation blanket.

• Do not cover the instruction manual. Keep it on the side of the

water heater or nearby for future reference.

• Do obtain new warning and instruction labels for placement on

the blanket directly over the existing labels.

teMperature-pressure relIef ValVe

This water heater is provided with a properly rated/sized and

certified combination temperature - pressure relief valve by the

manufacturer. The valve is certified by a nationally recognized

testing laboratory that maintains periodic inspection of production

of listed equipment of materials as meeting the requirements for

Relief Valves for Hot Water Supply Systems, ANSI Z21.22 • CSA

4.4, and the code requirements of ASME.

If replaced, the new valve must meet the requirements of local

codes, but not less than a combination temperature and pressure

relief valve rated/sized and certified as indicated in the above