Major components, Outback power technologies products, Customer supplied components – Outback Power Systems FLEXpower ONE System Overview User Manual

Page 3: Reference documentation, Page 1, System overview, Side view

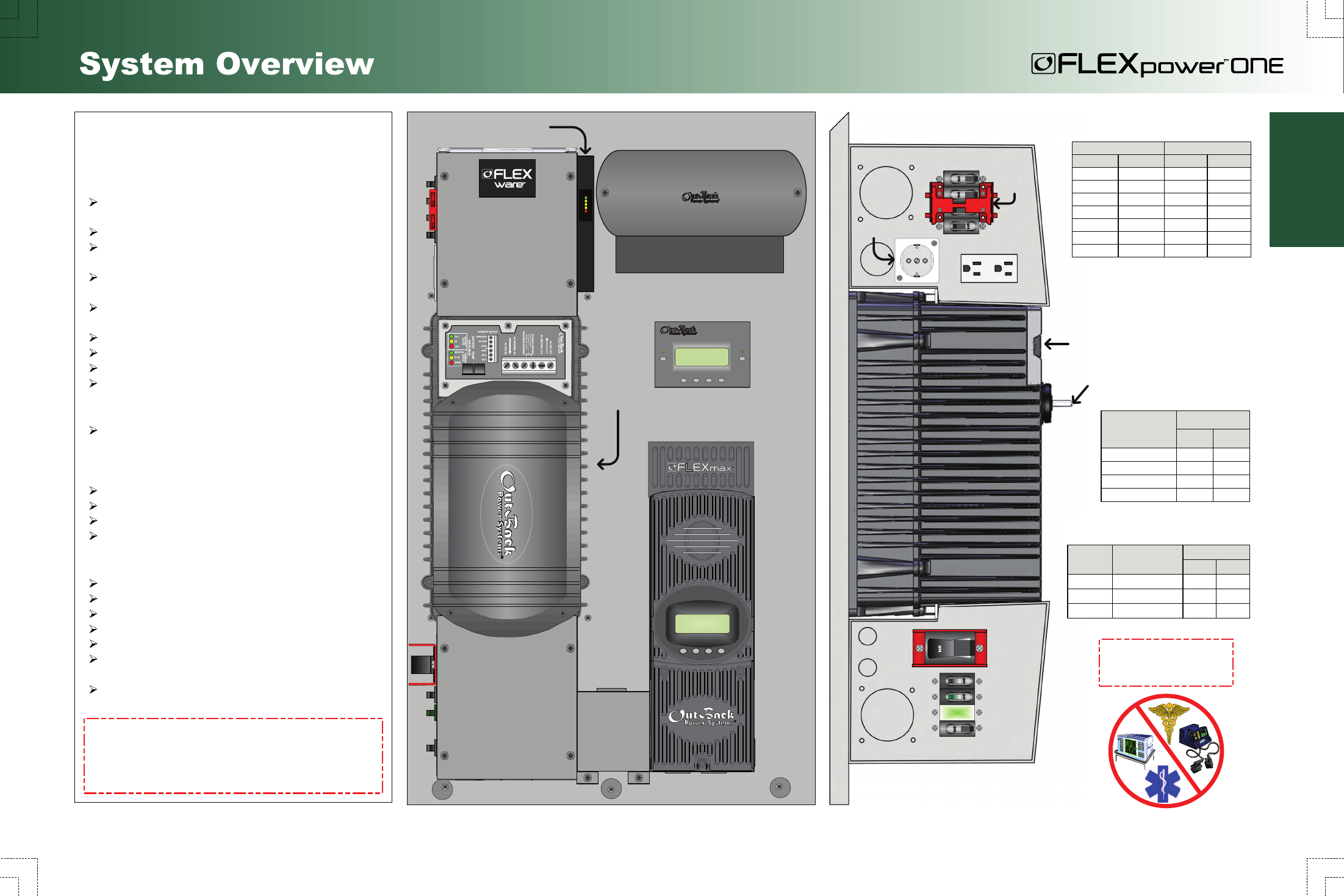

Major Components

OutBack Power Technologies

Products:

Inverter/Charger

(FX, VFX, GVFX or GTFX models)

FW250-AC-120V-NA

FW250-DC-125, FW250-DC-175, or

FW250-DC-250

System Display and Controller

(MATE2 or MATE3)

Charge Controller

(FLEXmax 80 or FLEXmax 60)

Remote Temperature Sensor (RTS)

Communications Manager (HUB4 or HUB10)

FLEXnet DC Monitor

Surge Protector

Customer Supplied Components:

AC Source:

~ Utility Grid (if available) or

~ AC Generator with circuit breaker or

overcurrent device

Main AC Distribution Panel

AC Distribution Sub-Panel (Load Panel)

Battery Bank (24 or 48 Vdc)

Photovoltaic (PV) Array and PV Combiner Box

Reference Documentation:

FLEXpower ONE Installation Manual

FX Inverter/Charger Installation Manuals

FX Operator’s Manuals

MATE Series or MATE3 Owner’s Manual

HUB Owner’s Manual

FLEXmax Series Charge Controllers

Owner’s Manual

FLEXnet DC Monitor Owner’s Manual

IMPORTANT:

All configurations must comply with local and national electric

codes. Consult your local electric authority to ensure

compliance. Actual wiring requirements may vary.

Factory wiring is not shown.

900-0094-01-00 Rev A.vsd\Wiring Info\2012-03-02

©2011 OutBack Power Technologies. All Rights Reserved.

Page 1

MATE

RTS

Inverter/

Charger

FW250-AC-120V-

NA

FW250-DC-125

(175 or 250)

Charge Controller

(FLEXmax 80)

System Display and

Controller (MATE2)

HUB Communication Manager

(HUB4 or HUB10)

System Overview

FLEXnet DC

AC IN

INV

MAIN----------------

3:02:14P

SUM STATUS SETUP ADV

In 23.2 V 0.0 A

Out 27.6 V 0.0 A

0.000 kW 0.0 kWH

AUX: OFF Sleeping

Surge Protector

(Inside)

MATE

RTS

AC Wire Sizes and Torque Values

AWG

In-lb

#14 - 10

20

#8

25

#6 - 4

35

#3

35

#2

40

#1

50

1/0

50

mm

2

2.5 – 6

10

16 – 25

35

35

50

70

Nm

2.3

2.8

4.0

4.0

4.5

5.6

5.6

Wire Size

Torque

It is recommended that conductors

be #6 AWG THHN copper, or larger,

rated to 75 °C (minimum)

unless local code requires otherwise.

Minimum DC Conductor

based on DC Breaker

Torque

In-lb

Nm

50

5.6

225

25.4

225

25.4

DC

Breaker

Conductor

Size

125

1/0 (70 mm

2

)

175

2/0 (70 mm

2

)

250

4/0 (120 mm

2

)

AC Breakers

GFCI Outlet

(120V models only)

GFCI Outlet

(240V models only)

DC Breakers

Battery Status

Monitor

PV Array

GFDI

IMPORTANT:

Not intended for use with

life support equipment.

Side View

Charge

Controller

Battery Bank

Mechanical

Interlock

(Bypass)

DC Terminals

Torque Data for Breaker Lugs

Breaker Stud

Torque

In-lb

Nm

M8

20

2.3

¼ - 20

35

4.0

5/16 - 18

50

5.6

3/8 - 16

225

25.4

AC Terminal

Compartment