Yetter 2967-122 Floating Residue Manager User Manual

Page 9

9

MAINTENANCE

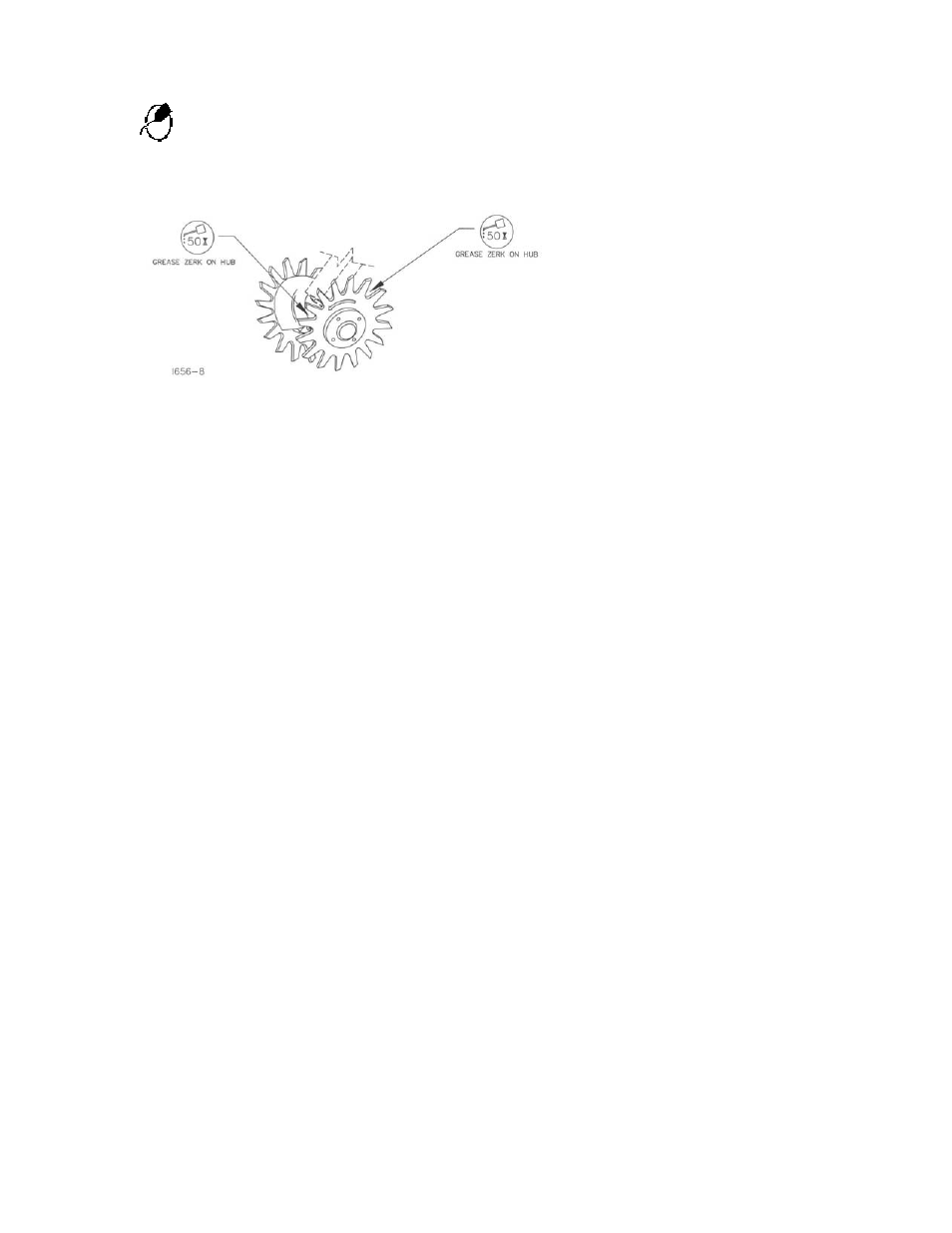

Lubrication Symbols

Lubricate with grease at hourly interval indicated on symbol.

Lubrication Intervals

IMPORTANT: The recommended service intervals are based on normal

conditions; severe or unusual conditions may require more frequent

lubrication.

Perform each lubrication and service procedure at the beginning and end of each

season.

Clean grease fittings before using grease gun, to avoid injecting dirt and grit into the

bearing. Replace any lost or broken fittings immediately. If a fitting fails to take

grease, remove and clean thoroughly, replace fitting if necessary. Also check for

failure of adjoining parts.

BEARING REPLACEMENT INSTALLATION

1. If you wish to be able to grease the bearings in the hubs, remove the seal

from one side of the bearings as illustrated before assembly. Otherwise the

bearings may be left “sealed for life”.

2. When assembling the spoke wheels, bearing assembly and hubcap, be sure

to align the grease transfer hole in the spoke wheel with the groove in the

hubcap and hole in the hub to allow grease passage.

3. Install/assemble the wheels, hubs and caps. IMPORTANT: THE 2527-530

WASHER MUST BE INSTALLED OR THE WHEEL AND HUB ASSEMBLY

WILL FALL OFF DURING USE.

4. Grease the wheel/hub/bearing assembly.