Yetter 2967-122 Floating Residue Manager User Manual

Page 8

8

MAINTENANCE

Lubrication

CAUTION: To help prevent serious injury or death to you or others caused

by unexpected movement, service machine on a level surface. Lower

machine to ground or sufficiently lock or block raised machine before

servicing. If machine is connected to tractor, engage parking brake and

place transmission in "PARK", shut off engine and remove key. If machine

is detached from tractor, block wheels and use shop stands to prevent

movement.

CAUTION: Do not clean, lubricate, or adjust machine while in motion.

Use grease based on NLGI consistency numbers and the expected air temperature

range during the service interval.

Use a multi-purpose lithium, water resistant, moderate speed, and NLGI grade

#2 grease.

Other greases may be used if they meet the following NLGI Performance

Classification: GC-LB

IMPORTANT: Some types of grease thickener are not compatible with others.

Consult your grease supplier before mixing different types of grease.

Alternative Lubricants

Conditions in certain geographical areas may require special lubricants and

lubrication practices which do not appear in the operator's manual. If there are any

questions, consult Yetter Manufacturing Co. to obtain latest information and

recommendation.

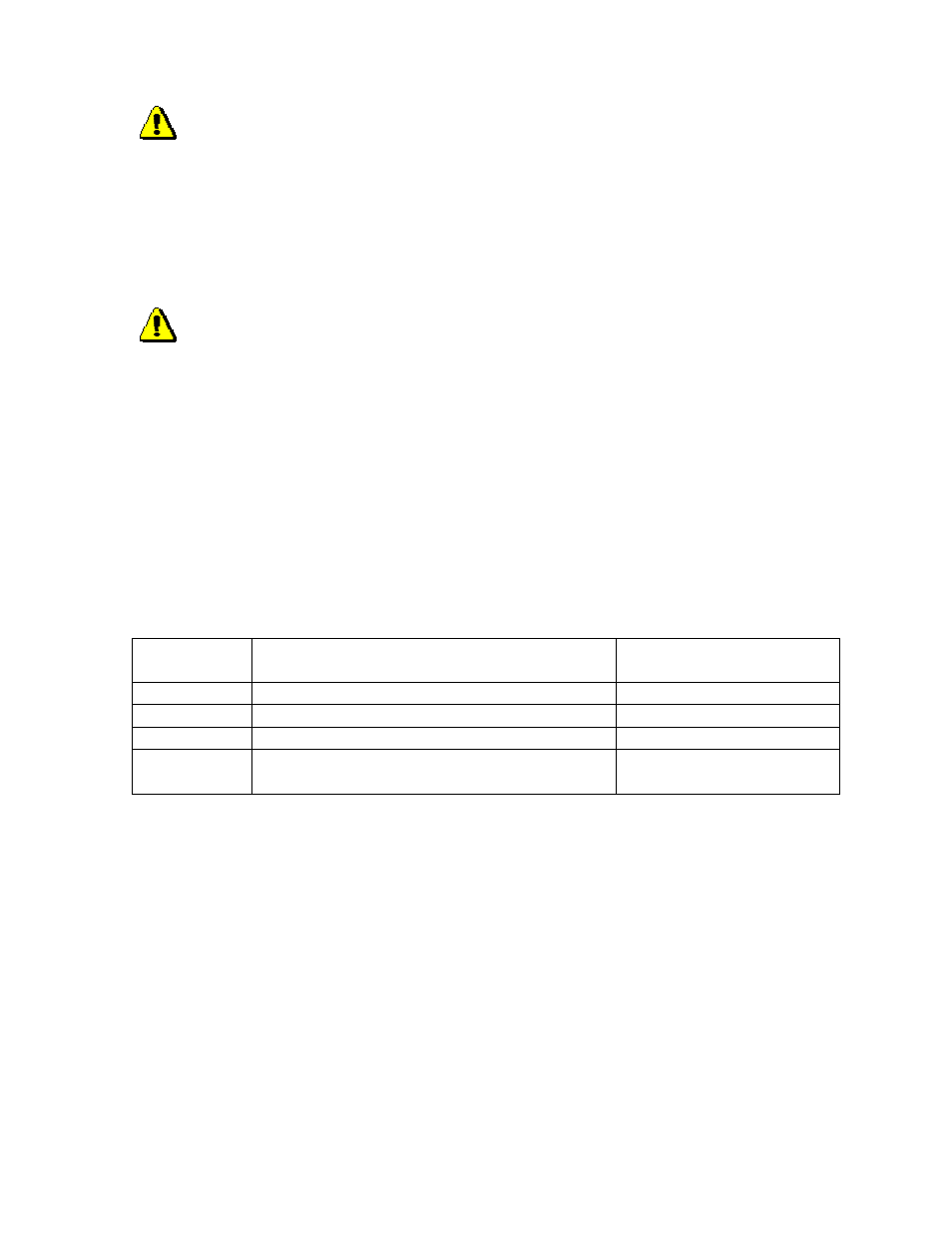

PART #

DESCRIPTION

OUNCES OF GREASE

2967-404

13” TAPER TOOTH R.M. WHEEL

1.12 OZ

2967-602

13” SHARK TOOTH R.M. WHEEL

1.12 OZ

2967-186

FLOATER WHEEL KIT W/R.M. WHEEL

2.08 OZ

2967-596

HEAVY DUTY OR BEVEL R.M. WHEEL

W/ FLOATER WHEEL KIT

2.40 OZ

Storing Lubricants

Your machine can operate at top efficiency only if clean lubricants are used.

Use clean containers to handle all lubricants.

Store them in an area protected from dust, moisture and other contaminants.