A guide to damper tuning – Penske Racing Shocks 8760 Series User Manual

Page 16

16

A Guide To Damper Tuning

The ultimate purpose of a shock is to work together with the spring to keep the tire on the track. In compression

(bump) to help control the movement of the wheel and in rebound to help absorb the stored energy of the

compressed spring.

Breaking down the shaft speeds to chassis movement can be done from the data taken from on board data

acquisition and/or actual test sessions.

Where we find the biggest advantages with low speed adjusters is looking at the chassis in the plane of the four

wheels in relation to chassis movement in roll and pitch and how quickly weight is transferred to each corner in

order to load the tire sooner or later, depending on track conditions.

Usually in rain or low grip situations allowing more bleed or less low speed damping is desirable to delay tire

loading upon initial roll.

In dry high grip conditions adding damping or restricting bleed will load the tire sooner upon initial roll increasing

platform stability.

In pitch situations on smooth surfaces under braking, increasing low speed damping or restricting bleed will help

load the tires for entry or mid corner. If the tire begins bouncing under braking usually an increase in high speed

compression will calm this down.

If the chassis feels like it is moving around too much relative to the track, increasing low speed damping or

restricting bleed will overall firm up the chassis and give it a crisp feel or a better sense of feel in the car. This is

why most drivers like this adjustment; as increasing low speed compression seems to give the driver better or

quicker feedback from the chassis, resulting in a higher confidence in the car.

A car with too much low speed damping will usually lack grip in change of directions, cannot put power down in

slower corners (wheel spin) and lack overall grip after initial turn in.

If traction is a problem coming off slow corners, reducing low speed damping or adding more bleed will help

weight transfer at the rear thus increasing traction.

We like to look at high speed adjustments as individual movements at any of the four corners, caused by an

input from the circuit or an exaggerated action by the driver. This adjustment is less forgiving than low speed,

because of its large range of adjustment which can help or hurt the balance of the car. It is straight forward on

how to adjust from simple driver’s inputs, in regards to if the car feels too soft or stiff in the bumpier sections of

the circuit.

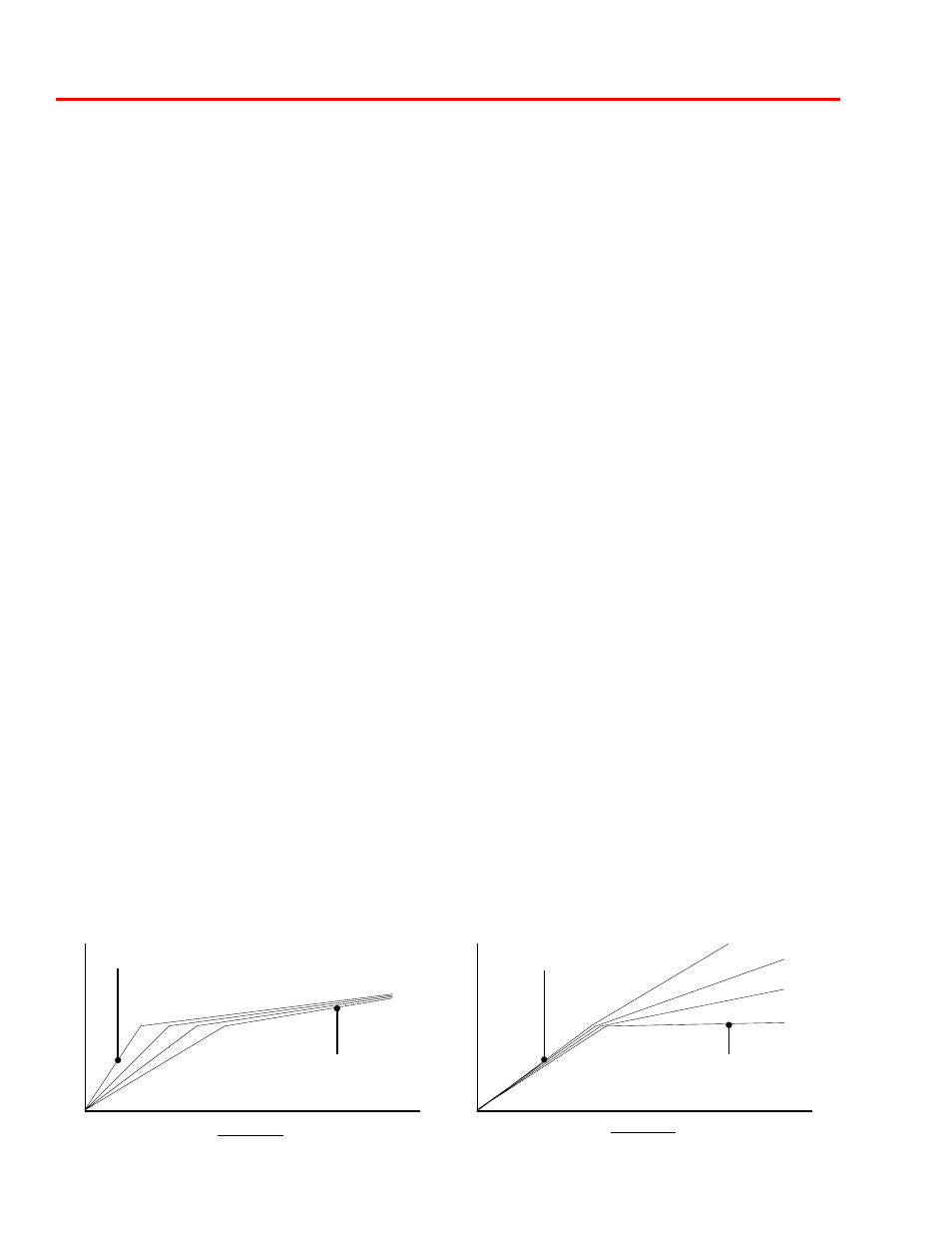

One of the most important things to know about these adjusters is their relative position to one another. If for

instance you have the low speed set at 25 to 30 clicks (soft), the range of high speed adjustment will be less-

ened. Or in the opposite direction, if the high speed is set at 0 to 1 (off soft), the low speed adjustment range will

be lessened.

Also, when making a big adjustment in high or low speed, the change will affect the other in a small percentage.

As an example, the high speed is set at (+4) and the low speed at (-6). Now you want to set the low speed to

(-2), this will also increase a percentage of the high speed force figure. By dropping the high speed from (+4)

to (+3) would compensate for this low speed change so the overall “damper curve” would remain intact.

The more experience you have with these the easier it will become to recognize what changes can occur in

relation to different valvings. The tendency of these circuits to “cross talk” is greatly reduced in our new

digressive CD piston (part # AS-76DIGCDUP).

The rebound adjuster consists of a needle metering flow across a hole. This metered flow bypasses the main

piston/shim assembly until flow is choked off. The shims then modulate the flow.

FORCE

FORCE

VELOCITY (SHAFT SPEED)

LOW SPEED HIGH SPEED

VELOCITY (SHAFT SPEED)

LOW SPEED HIGH SPEED

Large Amplitude Change

Small Amplitude Change

Large Amplitude Change

Small Amplitude Change

LOW SPEED ADJUSTMENT EXAMPLE

HIGH SPEED ADJUSTMENT EXAMPLE