Gauge connection (cont), Limited warranty and service procedures, B. mechanical oil pressure – Equus 8468 - 2-5/8 Voltmeter User Manual

Page 2: C. mechanical temperature

© 2004 IEC - All Rights Reserved

GAUGE CONNECTION (Cont)

4

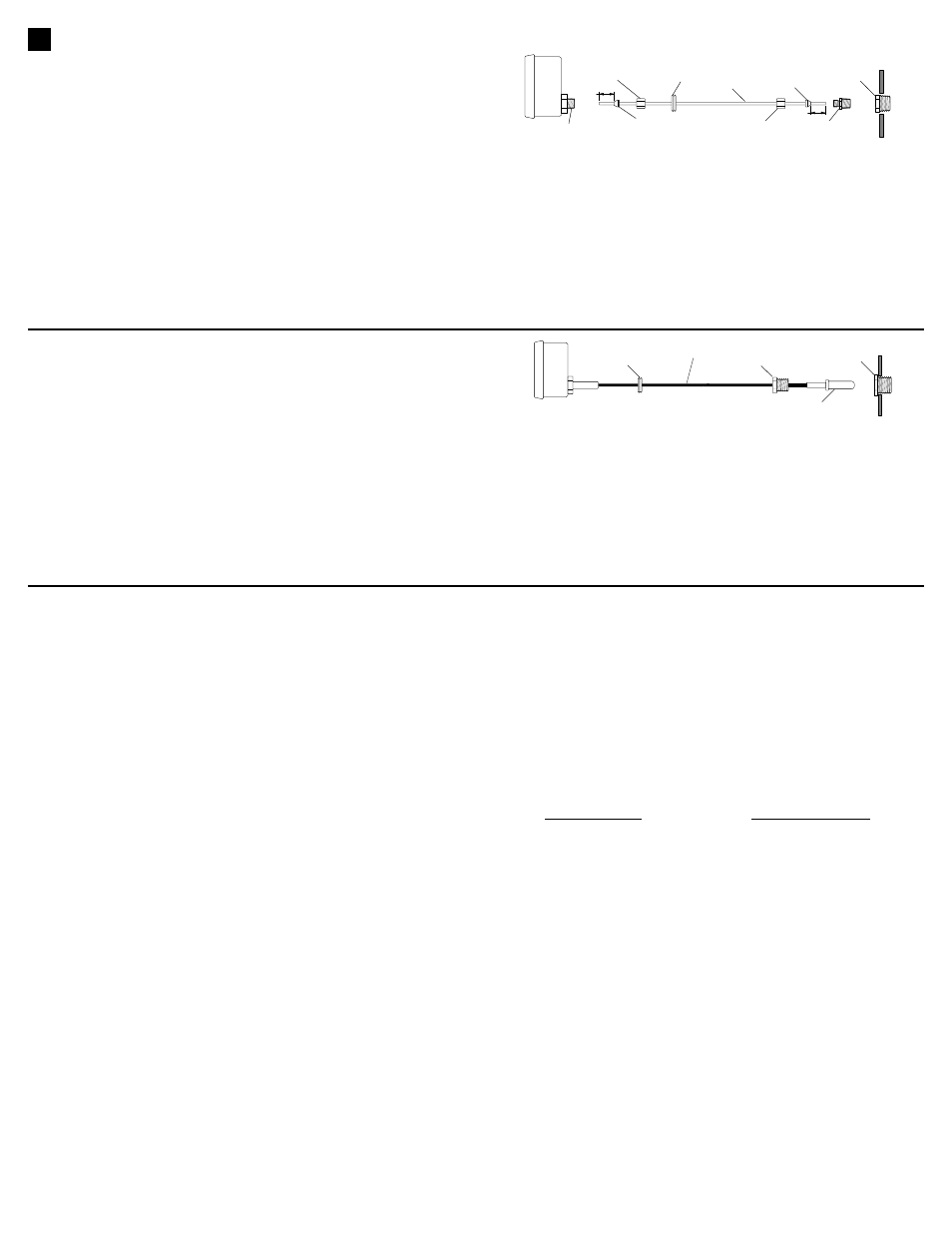

B. MECHANICAL OIL PRESSURE

NOTE: Before installation, use shop cloths and drip pans to protect interior

from potential vehicle leaks.

1. Determine routing for nylon tubing. Use an existing firewall grommet, or drill

a 3/8” (9.53 mm) diameter hole through firewall to accommodate nylon tub-

ing. Install a rubber grommet (purchased separately) in hole, use shrink

tubing to protect nylon tubing from chaffing or other damage.

NOTE: Some gauges require a tubing kit (purchased separately) for instal-

lation.

2. Connect nylon tubing to gauge using compression sleeve and compression

nut. Tighten compression nut until tubing is secure.

3. Route nylon tubing through grommet in firewall.

4. Locate correct oil pressure port on engine and, if required, install proper

adapter from gauge kit.

NOTE: Adapters for most Domestic/Asian vehicles included (excludes 6500

Series gauges). Additional adapters purchased separately.

5. Connect nylon tubing to pressure port adapter using tube connector, com-

pression sleeve and compression nut. Tighten compression nut until tubing

is secure.

6. Secure tubing along its route to prevent damage from sharp edges, moving

parts or hot engine components.

7. Reconnect negative (-) battery cable. Start and run engine for approxi-

mately 30 seconds. Turn off engine and check gauge installation for leaks.

Tighten or reseal joints as needed and retest.

OPTIONAL

GROMMET

COMPRESSION

SLEEVE

COMPRESSION

NUT

COMPRESSION

NUT

COMPRESSION

SLEEVE

ADAPTER

*

*

USE TEFLON SEALING TAPE ON NOTED THREAD JOINTS.

NYLON

TUBING

ENGINE

BLOCK

1/8"

1/8"

GAUGE

PORT

*

TUBE

CONNECTOR

*

Figure 5. Mechanical Oil Pressure Gauge Connections

C. MECHANICAL TEMPERATURE

1. Determine routing for temperature sensor. Use an existing firewall grom-

met, or drill a 7/8” (22.23 mm) hole through firewall to accommodate capil-

lary tube with sensor. Install a rubber grommet (purchased separately), in

hole to protect capillary tube from chaffing or other damage.

CAUTION: The capillary tube is a sealed, pressurized tube that is filled with

Ether gas. NEVER CUT THE TUBE OR ATTEMPT TO REMOVE IT FROM

THE GAUGE PORT.

2. Route capillary tube through grommet in firewall.

3. Remove the vehicle's existing temperature sending unit. Install the proper

size adapter (an adapter must be used to properly seat temperature

sender; see section 1, item 6) in sender hole and tighten securely. Insert

temperature sensor in adapter and tighten sensor nut securely. DO NOT

ROTATE SENSOR OR CAPILLARY TUBE WHILE TIGHTENING NUT OR

CAPILLARY TUBE MAY BE DAMAGED.

NOTE: Adapters for most Domestic/Asian vehicles included (excludes 6500

Series gauges). Additional adapters purchased separately.

4. Secure capillary tube along its route to prevent damage from sharp edges,

moving parts or hot engine components. DO NOT CRIMP, KINK OR MAKE

SHARP BENDS IN THE CAPILLARY TUBE.

5. Reconnect negative (-) battery cable. Start and run engine and check

gauge installation for leaks. Tighten or reseal joints as needed and retest.

OPTIONAL

GROMMET

TEMPERATURE

SENSOR

ENGINE

BLOCK

CAPILLARY TUBE

OPTIONAL

ADAPTER

*

*

USE TEFLON SEALING TAPE ON NOTED THREAD JOINTS.

SENSOR

NUT

*

Figure 6. Mechanical Water Temperature Gauge Connections

The Manufacturer warrants to the original purchaser that this unit is free of defects in

materials and workmanship under normal use and maintenance for a period of one (1)

year from the date of original purchase. If the unit fails within the one (1) year period, it

will be repaired or replaced, at the Manufacturer's option, at no charge, when returned

prepaid to the Technical Service Center with Proof of Purchase. The sales receipt may

be used for this purpose. Installation labor is not covered under this warranty.

All replacement parts, whether new or re-manufactured, assume as their warranty

period for only the remaining time of this warranty. This warranty does not apply to

damage caused by improper use, accident, abuse, improper voltage, service, fire,

flood, lightning, or other acts of God, or if the product was altered or repaired by any-

one other than the Manufacturer's Technical Service Center. Consequential and inci-

dental damages are not recoverable under this warranty. Some states do not allow

the exclusion or limitation of incidental or consequential damages, so the above lim-

itation or exclusion may not apply to you.

This warranty gives you specific legal rights, and you may also have other rights,

which vary from state to state. No portion of this warranty may be copied or dupli-

cated without the expressed written permission from the Manufacturer.

Obtaining Warranty Service:

Products requiring service should be returned as follows:

1. Call the Technical Service Center to obtain a Return Reference Number:

USA & Canada = 1-800-544-4124

Other = 714-241-6805

2. Package the product carefully to prevent shipping damage

3. Include your name, return address, and a day contact phone

4. Enclose a copy of the dated sales receipt

5. Describe the problem

6. Ship prepaid to: Technical Service Center, 17291 Mt. Herrmann Street, Fountain

Valley, CA 92708 U.S.A.

Phone: 1-800-544-4124 or 714-241-6805 Fax: 714-432-7910

Web: www.iEQUUS.com

Email: [email protected]

LIMITED WARRANTY AND SERVICE PROCEDURES

- 8454 - 2-5/8 Oil Pressure Gauge 8453 - 2-5/8 Water Temperature Gauge 8444 - 2-5/8 Mechanical Oil Pressure Gauge 8442 - 2-5/8 Mechanical Water Temperature Gauge 8268 - 2 Voltmeter 8262 - 2 Electric Water Temperature Gauge 8244 - 2 Mechanical Oil Pressure Gauge 8242 - 2 Mechanical Water Temperature Gauge 8200 - 2 Chrome Volt Triple Gauge Kit 8164 - 1-1/2 Electric Oil Pressure Gauge 8100 - 1-1/2 Volt Triple Gauge Kit 7268 - 2 Chrome Voltmeter 7244 - 2 Chrome Mechanical Oil Pressure Gauge 7242 - 2 Chrome Mechanical Water Temperature Gauge 7241 - 2 Chrome Mechanical Water Temperature Gauge 7234 - 2 Chrome Mechanical Oil Pressure Gauge 7232 - 2 Chrome Mechanical Water Temperature Gauge 7200 - 2 Chrome Volt Triple Gauge Kit 7068 - 3-3/8 Chrome Tachometer 6268 - 2 Black Voltmeter 6262 - 2 Electric Water Temperature Gauge 6244 - 2 Mechanical Oil Pressure Gauge 6242 - 2 Mechanical Water Temperature Gauge 6234 - 2 Mechanical Oil Pressure Gauge 6232 - 2 Mechanical Water Temperature Gauge 6200 - 2 Volt Triple Gauge Kit 6100 - 1-1/2 Volt Triple Gauge Kit