Preventing test port connector damage, Safety recommendations – Boonton Average & CW Power Sensors User Manual

Page 4

Wireless Telecom Group Inc.

25 Eastmans Rd

Parsippany, NJ 07054

United States

Tel:

+1 973 386 9696

Fax:

+1 973 386 9191

www.boonton.com

© Copyright 2012

All rights reserved.

B/SensConnCare/0212/EN

Note: Specifications, terms and conditions

are subject to change without prior notice.

Preventing Test Port Connector Damage

• Keep connectors clean and protect using the plastic end

caps provided with each sensor.

• Inspect connectors regularly, and look for metal debris,

scratches or dents.

• Clean contact surface and threads with clean & dry com-

pressed air.

• Align connectors first and only rotate the connector nut.

• Always follow MIL-C-39012 standards for making a con-

nection

• A MIL-C-39012 or precision type “N” connector is recom-

mended for the RF line signal source connection

• After proper alignment, rotate the connector nut by hand

to connect, or disconnect the connector of the sensor from

a signal source or power meter.

• If “N” connector is not equipped with a hex, it is recom-

mended to use a specified mating torque.

• Do not over-tighten the connector by using the sensor

body for additional leverage

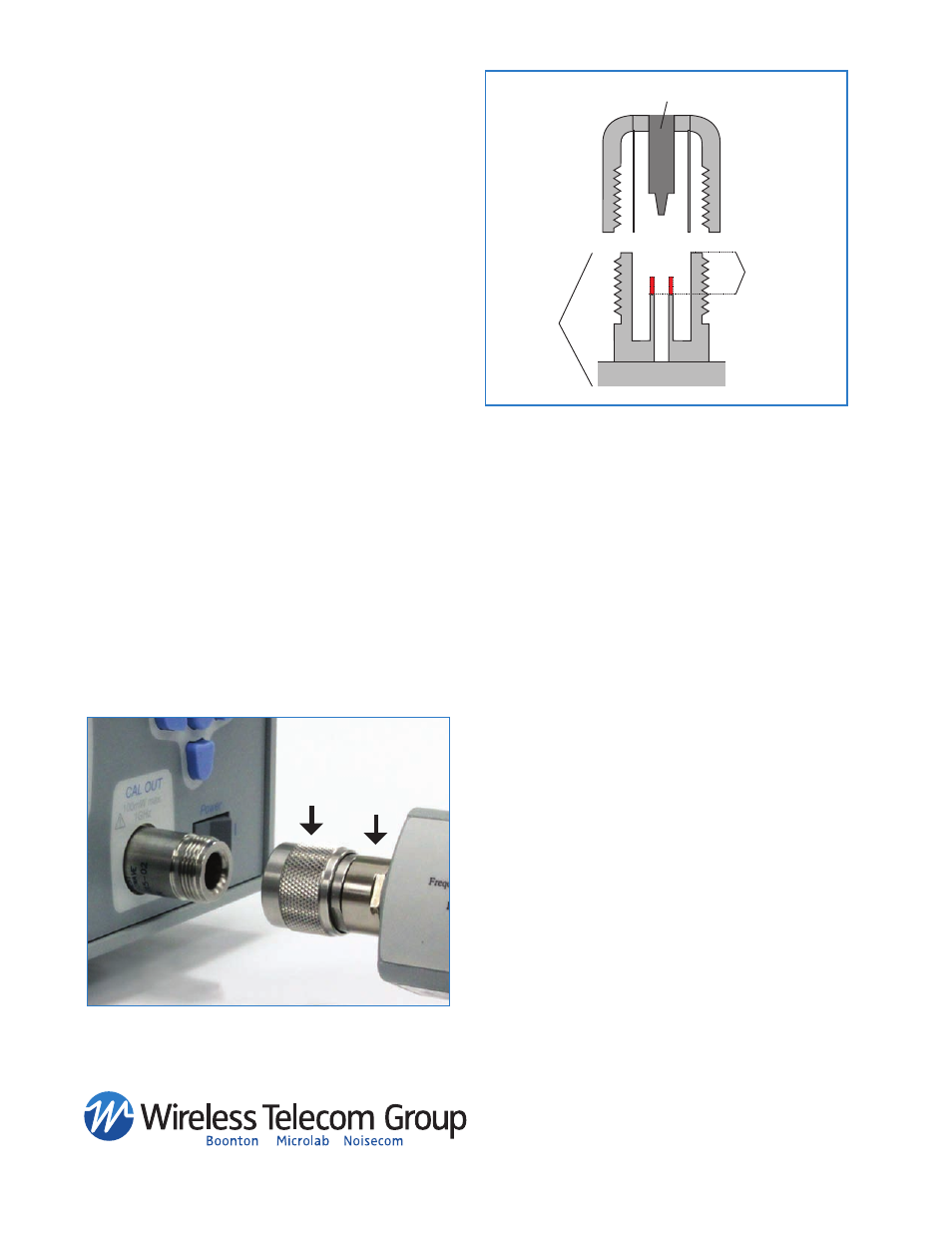

1) Only rotate the connector nut, DO NOT use the sensor body

or device to tighten the connector.

2) Do not use a torque wrench to tighten the connector.

3) Do not use a connector with deformed threads, or a bent or

broken conductor.

4) Do not touch mating-plane surfaces with oily, or wax-like

non-conductive substances

5) Do not apply a lateral force to the center conductor

Safety Recommendations

Figure 12.

TIGHTEN

HOLD

Type-N (m)

Type-N(f)

Required Depth

Conductor Pin

Bulkhead

NOTE: A common cause for “N” Type Connector damage is a bulk-

head without the required mating connector depth (Red Projection).