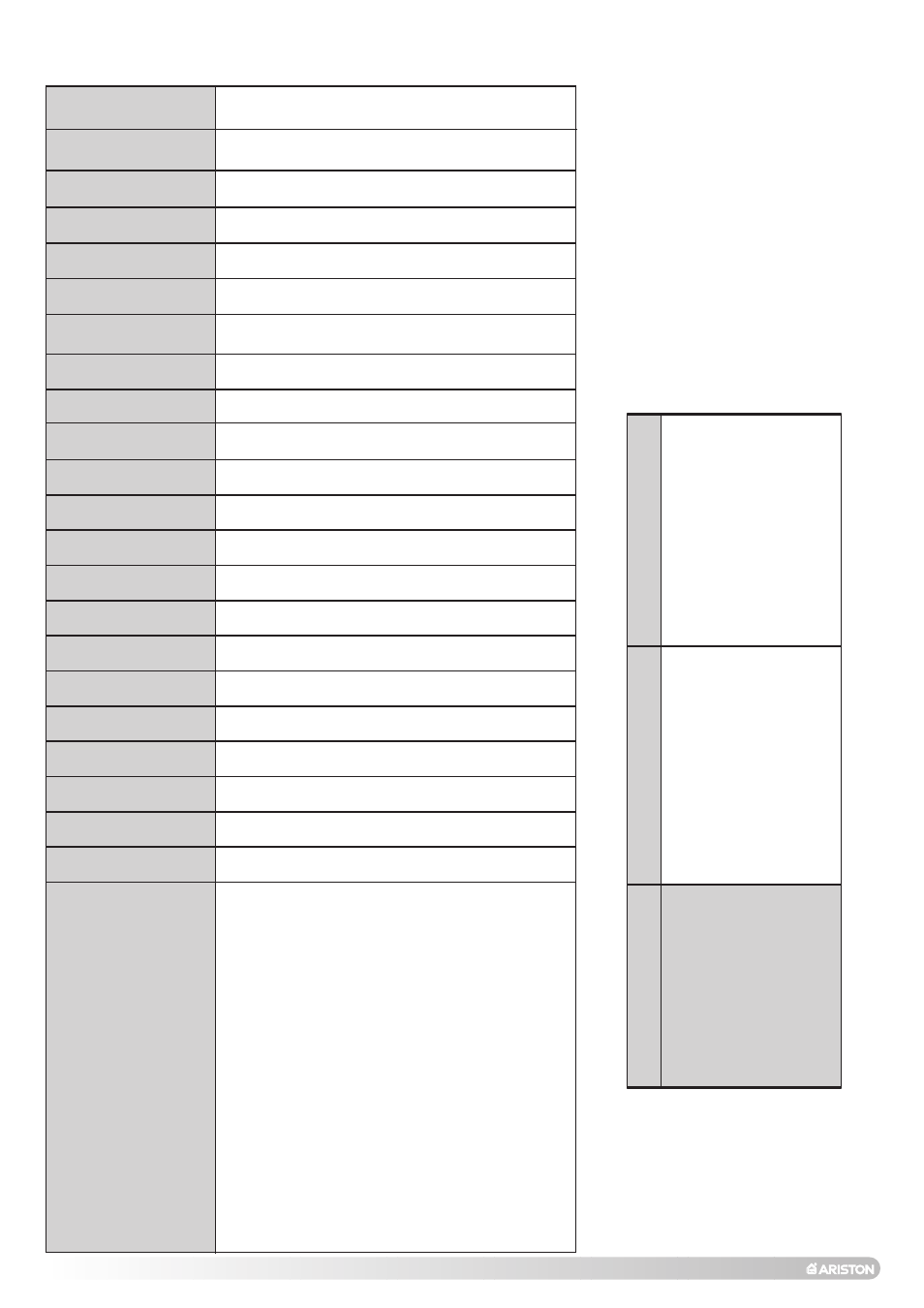

Technical information – Ariston Unvented Hot Water Storage Cylinders User Manual

Page 22

22

6.

TECHNICAL INFORMATION

12

3.5

3.5

6

7/90

3.5

240

3

480

(1)

(3)

60

-

-

-

-

1.15

27

12

3.5

3.5

6

7/90

3.5

240

3

480

(1)

(3)

120

-

-

-

-

1.26

41

*

T

o pressure reducing v

alv

e **Pr

imar

y circuit

80

°C

, 1m

3

/h circulation

.

(1)

Single Phase

(2)

Single Phase/Three Phase

(3)

BS 3456 Section 2.21

ST ProT ech 50

ST ProT ech 80

ST ProT ech 100

STD ProT ech 100

STD/STD ProT ech 125

STD/STD ProT ech 150

STD/STD ProT ech 210

STD/STD ProT ech 300

STI/STI ProT ech 125

STI/STI ProT ech 150

STI/STI ProT ech 210

STI/STI ProT ech 300

ITD 125

ITD 150

ITD 210

High Capacity

500 STD UK

High Capacity

500 STI UK

12

3.5

3.5

6

7/90

3.5

240

3

480

(1)

(3)

90

-

-

-

-

1.40

40

12

3.5

3.5

6

7/90

3.5

240

3

350

(1)

(3)

120

-

-

-

-

1.50

29

12

3.5

3.5

6

7/90

3.5

240

3+3

350

(1)

(3)

150

-

-

-

-

1.70

33

12

3.5

3.5

6

7/90

3.5

240

3+3

350

(1)

(3)

175

-

-

-

-

1.90

40

12

3.5

3.5

6

7/90

3.5

240

3+3

350

(1)

(3)

350

-

-

-

-

2.85

85

12

3.5

3.5

6

7/90

3.5

240

3+3

350

(1)

(3)

240

-

-

-

-

2.10

45

12

3.5

3.5

6

7/90

3.5

240

3

350

(1)

(3)

150

3.5

20.5

0.75

18

2.00

41

12

3.5

3.5

6

7/90

3.5

240

3

350

(1)

(3)

175

3.5

26.7

0.90

22

2.20

51

12

3.5

3.5

6

7/90

3.5

240

3

350

(1)

(3)

240

3.5

26.7

0.90

26

2.40

56

12

3.5

3.5

6

7/90

3.5

240

3+3

350

(1)

(3)

150

-

-

-

-

1.70

13

12

3.5

3.5

6

7/90

3.5

240

3

350

(1)

(3)

350

3.5

26.7

0.90

40

2.85

95

12

3.5

3.5

6

7/90

3.5

240

3+3

350

(1)

(3)

175

-

-

-

-

1.90

14

12

3.5

3.5

6

7/90

3.5

240

3+3

350

(1)

(3)

240

-

-

-

-

2.10

20

ITD 300

12

3.5

3.5

6

7/90

3.5

240

3+3

350

(1)

(3)

350

-

-

-

-

2.85

31

ITI 125

ITI 150

ITI 210

12

3.5

3.5

6

7/90

3.5

240

3

350

(1)

(3)

150

3.5

20.5

0.75

18

2.00

17

12

3.5

3.5

6

7/90

3.5

240

3

350

(1)

(3)

175

3.5

26.7

0.90

22

2.20

21

12

3.5

3.5

6

7/90

3.5

240

3

350

(1)

(3)

240

3.5

26.7

0.90

26

2.40

27

ITI 300

12

3.5

3.5

6

7/90

3.5

240

3

350

(1)

(3)

240

3.5

26.7

0.90

26

2.85

37

12

3.5

3.5

6

7/90

3.5

240/415

6

400

(2)

(3)

290

-

-

-

-

3.60

130

12

3.5

3.5

6

7/90

3.5

240/415

6

400

(2)

(3)

290

3.5

31.8

1.50

54

3.60

149

Model

Time taken to raise tempera

ture

from 15

˚C to 65

˚C

Time taken to raise 70% of th

e

stored volume to 65

˚C

STI/STI ProTech 125***

15 mins

13 mins

STI/STI ProTech 210***

24 mins

21 mins

ITI 125***

?? mins

?? mins

ITI 300***

?? mins

?? mins

High Capacity 500 STI***

44 mins

38 mins

Contract STD 100

2 hrs 30 mins

1 hr 15 mins

Contract STD 210

Contract STD 300****

1 hr 58 mins

2 hr 47 mins

1 hr 39 mins

1 hr 45 mins

*** Indirectly heated. F

igures obtained by WRc-N

SF Limited in accorda

nce with Test Criter

ia 1-50-220 & 1-50-2

22.

**** With 4kW upgrade kit

fitted. Figures obtained

by WRc-NSF Limited i

n accorcdance with

Test Criteria 1-50

-220 & 1-50-222.

ST

ProTech

50

***

63

mins

33

mins

ST ProTech 1

00

***

1 hr 56 mins

72

mins

Maxim

um

W

ater Supply Pressure*

bar

Oper

ating Pressure

bar

Expansion

V

essel Charge Pressure

bar

Expansion Relief

V

alv

e Setting

bar

Pressure &

Temper

ature Relief

V

alv

e Setting

bar/

°C

Pressure Reducing

V

alv

e Set Pressure

bar

Electr

ical Supply

V

Immersion Heater Rating

kW

Immersion Heater Length

mm

Immersion Heater

Type

Immersion Heater Ref

er

nce Number

Direct Reheat

Time

(Single Immersion Heater)

(

∆

T 50

°C)

mins

Maxim

um Pr

imar

y Pressure

bar

Indirect Coil Rating

kW

Coil Surf

ace Area

m

2

Indirect Reheat

Time (

∆

T 50

°C)**

mins

Heat Loss (kWh in 24h) @ 60

°C

Nett

W

eight

Kg

www.tradeplumbing.co.uk Call Sales On 08708034288

www.tradeplumbing.co.uk Call Sales On 08708034288