Instructions, Tools required for assembly, Vapor tight light assembly – LUMATEQ LK848-20-110-00 User Manual

Page 2: Mounting options, Technical specifications

LUMATEQ is a division of TACO Metals, Inc.

To view the entire portfolio of LUMATEQ products and for Warranty and Product Information, go to lumateq.com

Corporate Headquarters 50 NE 179 Street, Miami, FL 33162 • 305.770.2392 • Fax: 305.653.8569 ©2014 All Rights Reserved

INSTRUCTIONS

Note:

•

Always hire a licensed electrician for proper installation.

•

Always mount this fixture to a grounded junction/breaker box.

Tools Required for Assembly:

•

Phillips screwdriver

•

Pliers

Vapor Tight Light Assembly

1)

Turn off the power at the main fuse or breaker box.

2)

Thread wires through wire gland and back cover wire hole.

3)

Connect the wires to the wire terminal L to L, N to N then

fasten the wire gland.

4)

Attach the LED tubes to the lamp holder.

5)

Put the tube fixing board in the back cover, fixing poles

through the board’s holes. Then turn around the head of

fixing poles 90º to fix the board to back cover.

6)

Use the lens and back cover clips to attach lens

to back cover.

7)

Use the wall fixing clips to fix the light fi xture to wall.

8)

Turn on power at main fuse or breaker box.

Mounting Options

WARNING

IN

ST

R

U

C

-L

K8

48

-2

0-1

10

-0

0

Vapor Proof Kit (LK848-20-110-00)

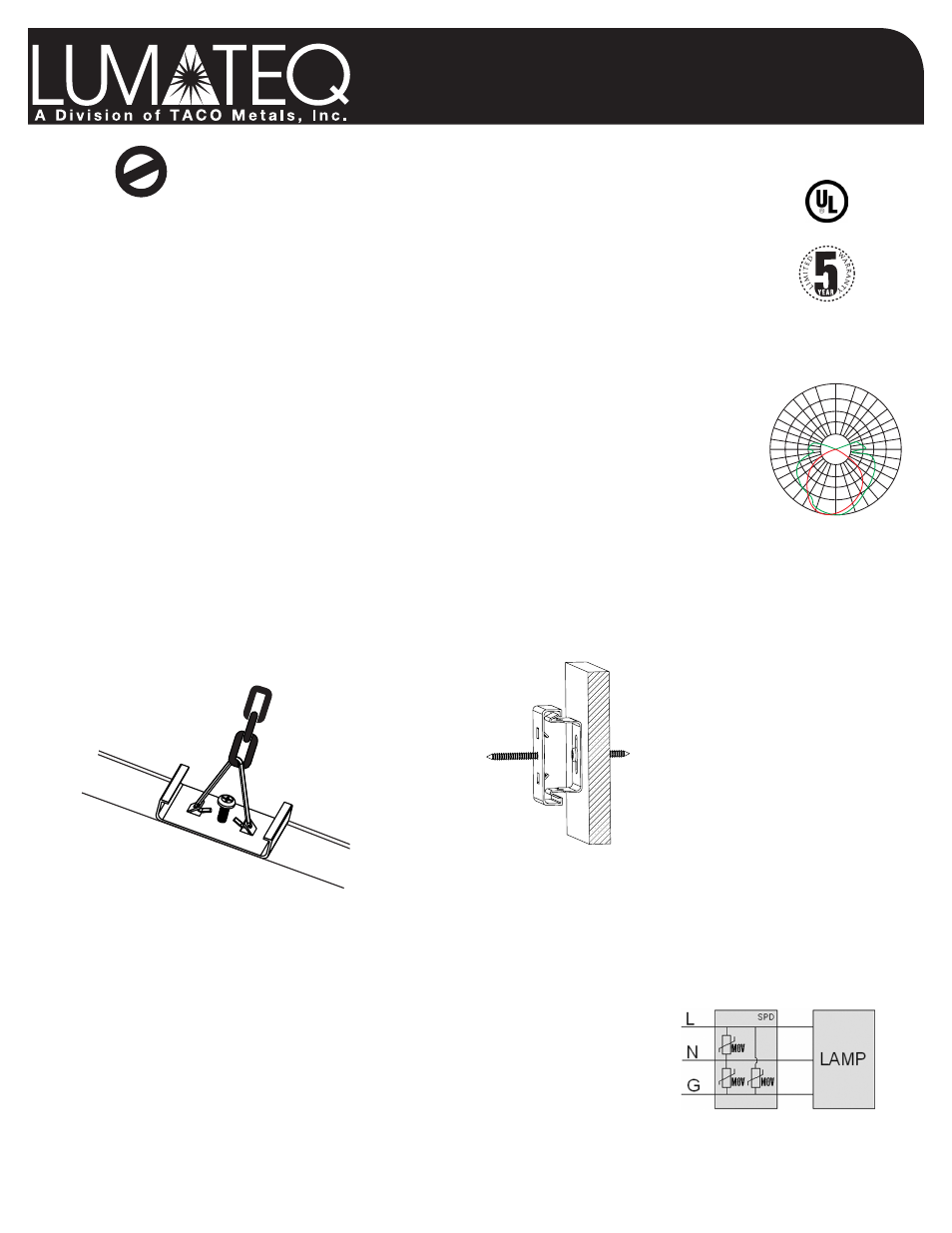

Chain Hanger Mount

Wall Mount Configuration

180

150

120

90

60

30

0

330

300

270

240

210

129.6°

*non-submersible

Technical Specifications:

• Operating Voltage: 110-277VAC

• Lamps: 2, 20-Watt

• Total Lumen Output: 3675 lm

• Amperage: 0.45 amps @120VAC

• Light Spread: 129.6°

• Operational Temperature Range:

-40°F/+180°F

• Material: Impact-Resistant Polycarbonate Lens

• Life Expectancy: Up to 50,000 hours

• UL-Approved for “Wet Location” (non-submersion)

• 5-Year Limited Warranty

Addendum:

LUMATEQ equipment that is directly connected to AC mains (e.g. 120/220/277VAC) can be damaged by short circuit and overload

conditions. In addition, lightning surges or load switching transients (originating outside the bulb) can create voltage spikes or ring waves

that can stress and ultimately damage components and render the fixture inoperable. Given that the value proposition for LED bulbs is

not only lower energy usage, but longer lifetimes, it will be crucial that transient voltage protection is taken into account to eliminate field

failures driven by the electrical environment.

Ensure the following steps are taken to decrease the chance of damage from short circuits and overload conditions:

1. Do not use mechanical timers or contactors to switch on the lamp. These contacts are known

to produce voltage spikes which are detrimental to the circuitry of the lamp.

It is recommended to use a solid state relay to provide power to the fixture.

2. Replace old circuit breakers, as corroded contacts on both the bus bar and internal contacts

of the breaker can cause destructive electrical spikes.

3. Use a surge protection device (SPD) spanning both Line, Neutral and Ground.

These devices contain MOV’s (a metal oxide varistor) which can help protect the LED bulb from

overvoltage surges and ring-wave effects by clamping short-duration voltage impulses as shown in drawing.